- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

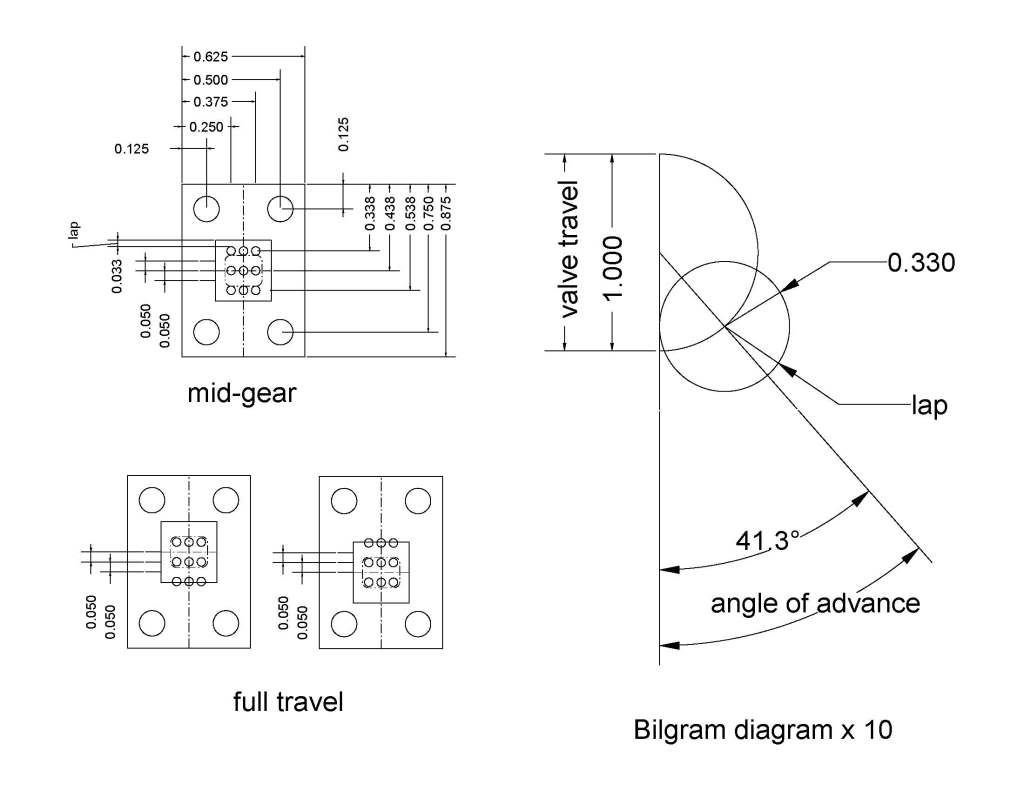

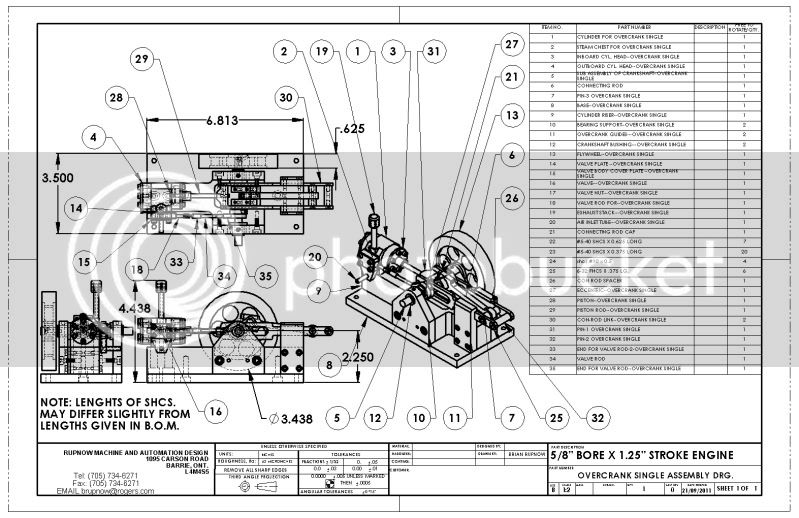

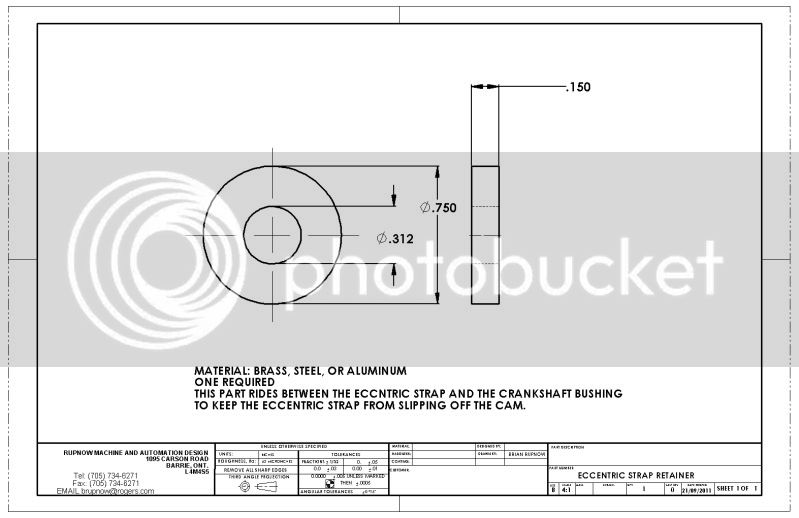

Brian, I drew out your valve assembly to scale and showed it through 135 degrees degrees of rotation. It looks like your inlet port is only open for about 90 degrees of rotation, between 45 degrees (second row down) to 135 degrees (last row). Wonder if maybe you need to increase the throw of your eccentric? Anybody else have any ideas in this area?

Chuck

Chuck