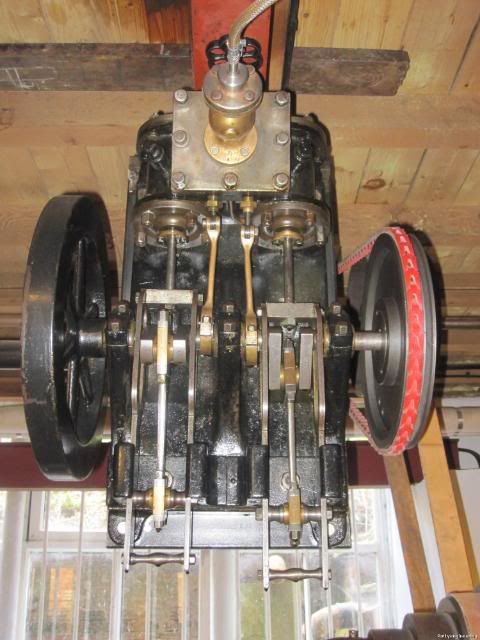

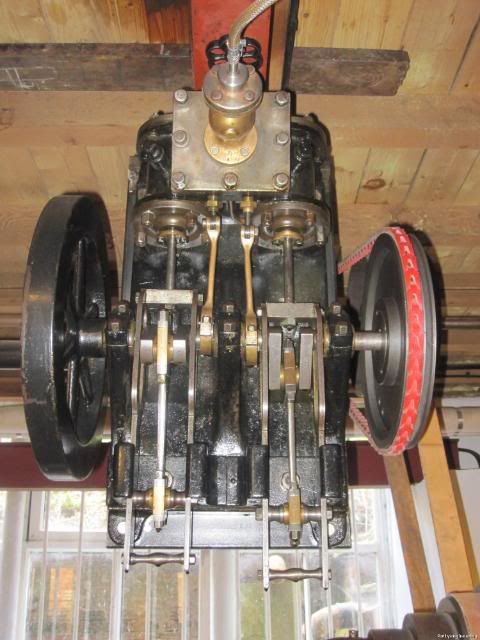

I was so taken by the twin cylinder Potty Overcrank Wall Engine designed and built by Sbwhart http://www.homemodelenginemachinist.com/index.php?topic=12367.0 that I may attempt to design and build a single cylinder Overcrank engine. One or two years ago I built my version of Elmers #33 mill engine, and it turned out quite fine. http://www.homemodelenginemachinist.com/index.php?topic=7340.0 (That was the engine that powers my Pumpjack.) It was a double acting single cylinder engine, with a slide valve arrangement similar to the valve arrangement on the Overcrank engine built by sbwhart. I will probably plaegerize the design of both the aformentioned engines and add some unique design elements of my own. Although I doubt that my work will ever approach that of Elmer Verbourg or Stew's, my engines do seem to run reasonably well. I will be simplifying the design, and configuring it to work with my favourite #5-40 fasteners. The Elmers#33 engine had a 1/2" bore and 1" stroke, while the Overcrank engine by sbwhart had a 20mm dia bore and a 36mm stroke. (Roughly 3/4" dia. and 1 1/2" stroke). I don't like to work on very small parts, however I don't want to design an engine so large that the modellers with smaller capacity lathes and mills are unable to build from my plans. The design will be done in Imperial units----(I can work in metric, but I'm much more comfortable with inches.) I will design in Solidworks 3D software, but the published drawings will be saved and posted here in a .pdf format. Welcome aboard, hope you enjoy the ride.----Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Overcrank Single Cylinder Engine

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jan 17, 2009

- Messages

- 887

- Reaction score

- 81

I'll be following along Brian sounds an interesting engine.

I,ve come across a few single cylinder wall engines that are described as over crank, but their layout is different to mine I'll try and find a few pics and post them.

Stew

I,ve come across a few single cylinder wall engines that are described as over crank, but their layout is different to mine I'll try and find a few pics and post them.

Stew

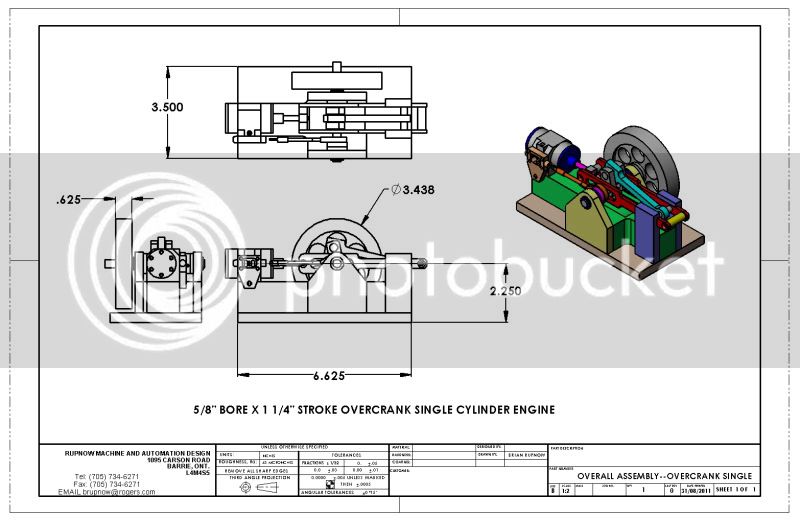

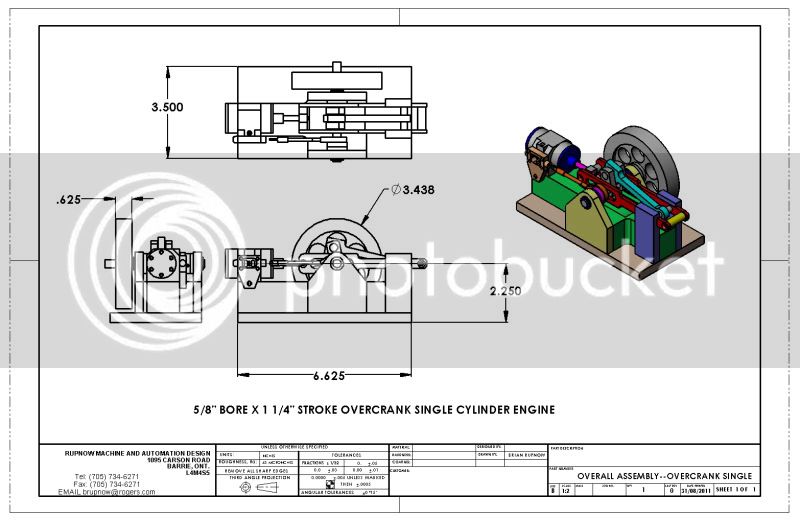

Thank you for the interest. I just checked my inventory of chucking reamers, and see that I have a brand new 5/8" diameter reamer. Since this is "half way" in size between the two engines which I am using as examples, I believe my engine is going to have a 5/8" bore and a 1 1/4" stroke. I like to machine my bores using a reamer, because it gets around the issue of tapered bores very nicely, and I can turn the piston diameter "to suit". This only works when I can machine my cylinder bore as a complete "thru-hole", and since the cylinder will have a bolt on endcap at both ends, this will work out very well.---Brian The following link will take you to the completed twin Overcrank engine by sbwhart.--an amazing piece of work.

http://www.homemodelenginemachinist.com/index.php?topic=14847.0

http://madmodder.net/index.php?topic=4201.msg52284#new

http://www.homemodelenginemachinist.com/index.php?topic=14847.0

http://madmodder.net/index.php?topic=4201.msg52284#new

- Joined

- Jan 17, 2009

- Messages

- 887

- Reaction score

- 81

The following link will take you to the completed twin Overcrank engine by sbwhart.--an amazing piece of work.

Thanks for you kind comment Brian, the single over crank I had in mind was the one Jason gave you the link for.

Thanks again

Stew

Where to begin,Where to begin!!! I have just realized a terrible set-back, namely that when my previous computer crashed early this summer, all of my 3d Solidworks files of my engines were lost. This is not insurmountable---I can recreate the 3D models from .pdf files. I am going to begin this project by designing the cylinder and valve body, as that will determine virtually everything elses position on the engine. I like the cylinder and valve set-up from my "Elmers 33 Kind of", so will use that as my basis for this engines cylinder.

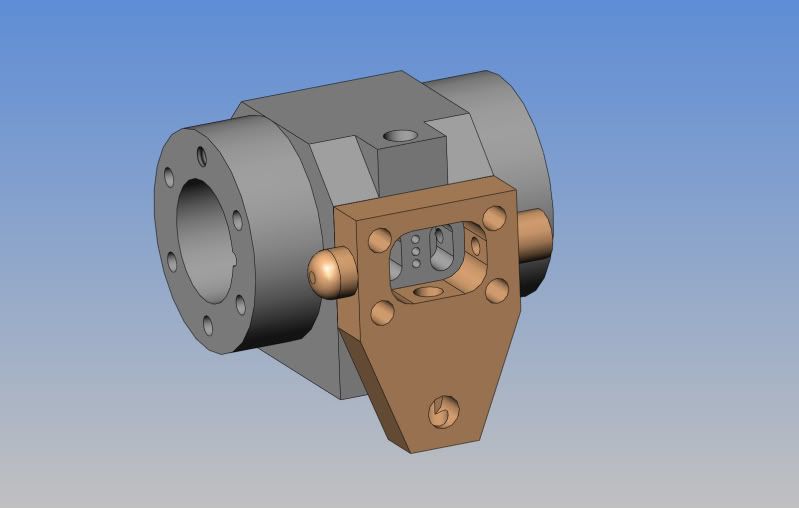

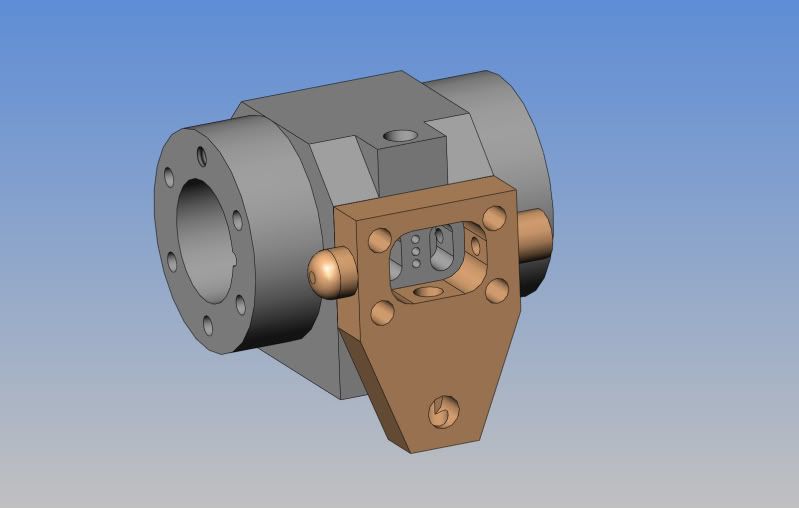

Well, there we go---that wasn't so bad!! Basically, I took the 1/2" bore x 1" stroke cylinder from my version of Elmers 33 mill engine, and redesigned it for a 5/8" bore x 1 1/4" stroke. I am going to use the exact same steam chest and valve, so I kept the cylinder the same in the critical area where the steam chest fits up to it. Of course the raw stock for the cylinder jumped up from 1.031" square to 1 1/4" square to accomodate the larger bore. The #33 engine cylinder was 1.375" long with a 1/4" thick piston and a 1" stroke, so I pro-rated sizes to accomodate a 1 1/4" stroke with a 1/4" thick piston, which changed the overall cylinder length to 1 5/8". This is my starting point only. As this design progresses I may have to change/re-arrange things, but now I have a "baseline" to work outward from.

- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

Brian

I'm in for the ride. Something different and unusual should get a lot of attention.

I wonder if someone could give me a definition of and "Overcrank Engine". There seems to be a fundamental difference between Stew's excellent example and the single cylinder engine in the above link. Although they are both "Wall Engines" on Stew's engine the crankshaft is positioned between the cylinder and the connecting rods and on the single cylinder referenced, the the crankshaft is beyond the connecting rod in the more usual configuration. True, it is very ornate and uses a wishbone connecting rod with an unusual central crosshead guide. It also has an extra eccentric to drive a couple of pumps but it is not the same configuration at all.

Either style should make for an interesting engine. or you might have something very different in mind. I'm just wondering what the term "overcrank" means.

Jerry

I'm in for the ride. Something different and unusual should get a lot of attention.

I wonder if someone could give me a definition of and "Overcrank Engine". There seems to be a fundamental difference between Stew's excellent example and the single cylinder engine in the above link. Although they are both "Wall Engines" on Stew's engine the crankshaft is positioned between the cylinder and the connecting rods and on the single cylinder referenced, the the crankshaft is beyond the connecting rod in the more usual configuration. True, it is very ornate and uses a wishbone connecting rod with an unusual central crosshead guide. It also has an extra eccentric to drive a couple of pumps but it is not the same configuration at all.

Either style should make for an interesting engine. or you might have something very different in mind. I'm just wondering what the term "overcrank" means.

Jerry

Thats enough for tonight. Wife and I drove 218 kilometers and back earlier today to look at a cottage and reserve it for a vacation next july. I'm whipped. Time to go drink my Sleepytime tea and read for a while. Tomorrow I'll get to the exciting part of this design.---Brian

Jerry---To me, an Overcrank engine is what Stew built. I don't know what I would call the other single in the link. It is interesting, but mine will mimick Stew's.

- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

Good plan.

Jerry

Jerry

Wow!!!---I actually felt like getting out of bed and "Getting at it" this morning. After a summers laziness, a new project gets my blood going!!!

- Joined

- Jan 17, 2009

- Messages

- 887

- Reaction score

- 81

Hi Bryan

I didn't follow the prototype exactly I used a little descretion mainly to help me make it, the main diference was with the main bearing housing, on the prototype this was a twp part casting, the crank bearing making up one part and the guide bars the other.

Her's a close up pic so you can see whats going on

Doing a single certainly gives you a lot of oportunity to try different layouts, you could have the slide bars outside of the bearing instead of inside, giving more room, or even put the ecentric on the outside.

I'll be watching with great interst.

Enjoy your build

Stew

I didn't follow the prototype exactly I used a little descretion mainly to help me make it, the main diference was with the main bearing housing, on the prototype this was a twp part casting, the crank bearing making up one part and the guide bars the other.

Her's a close up pic so you can see whats going on

Doing a single certainly gives you a lot of oportunity to try different layouts, you could have the slide bars outside of the bearing instead of inside, giving more room, or even put the ecentric on the outside.

I'll be watching with great interst.

Enjoy your build

Stew

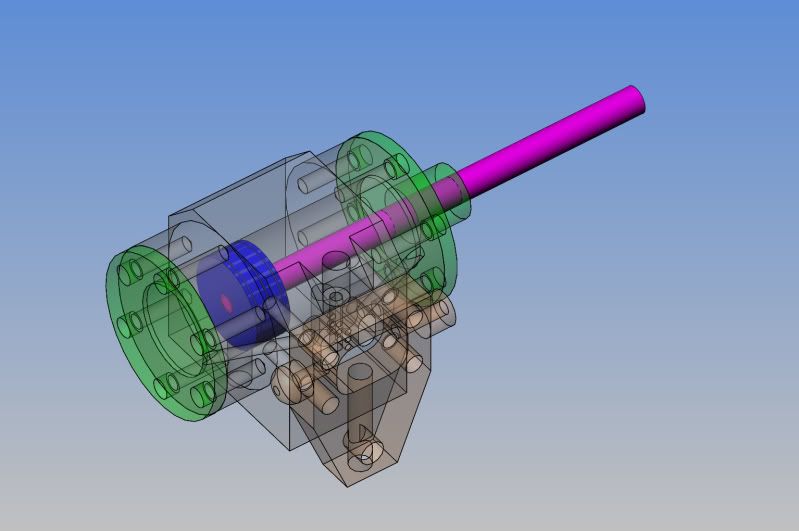

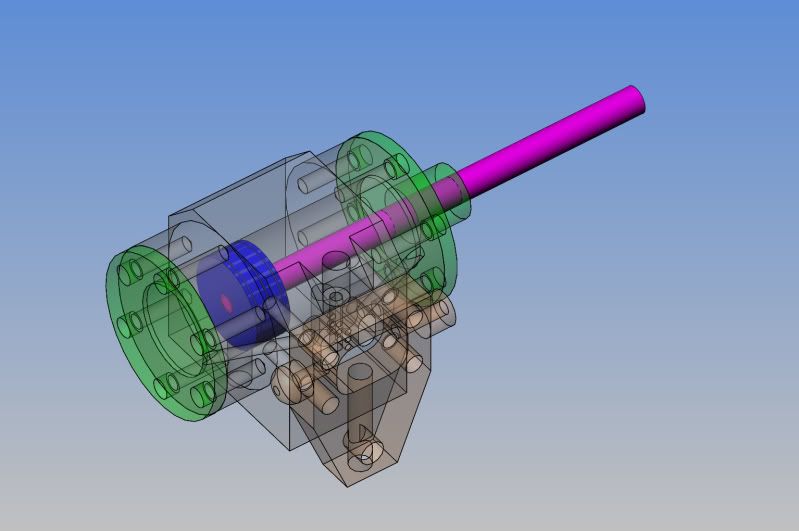

Thanks Stew.---After a quick check of available stock, a corporate decision has been reached to use 5/16" diameter stock for the crankshaft with 1/4" x 1/2" bar stock for the crankshaft "webs" or "throws" depending n what you call them. the crank will be built up, pinned, and loctited.

I am going to post one of Stew's video links here so I can find it for reference as I build.

http://www.youtube.com/watch?v=FBEsz7imfh8&feature=youtu.be

I am going to post one of Stew's video links here so I can find it for reference as I build.

http://www.youtube.com/watch?v=FBEsz7imfh8&feature=youtu.be

Lesmo

Well-Known Member

- Joined

- Mar 1, 2011

- Messages

- 142

- Reaction score

- 16

Hi Brian

I was just watching the video which I found by following the earlier link in your thread, and was mightily impressed by the slow running capability of this engine. I will certainly be on board for your version of it, and who knows, when I finish my present build which is your Elmer 2x scale, maybe I will have enough confidence to have a go myself. I just love those old steamers.

Les

I was just watching the video which I found by following the earlier link in your thread, and was mightily impressed by the slow running capability of this engine. I will certainly be on board for your version of it, and who knows, when I finish my present build which is your Elmer 2x scale, maybe I will have enough confidence to have a go myself. I just love those old steamers.

Les

Dang!!! I got this far this morning, and then an engineering job thats been on hold for 3 weeks was released. That means I have to stop this fun stuff for a while and do some real "money earning" work for a bit. Don't ya just hate it when you have to stop playing so you can earn some dirty old money!!!

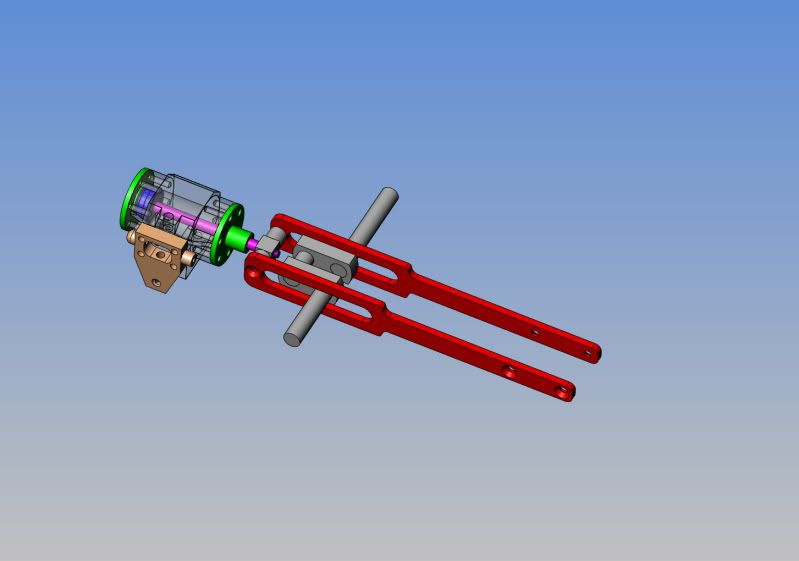

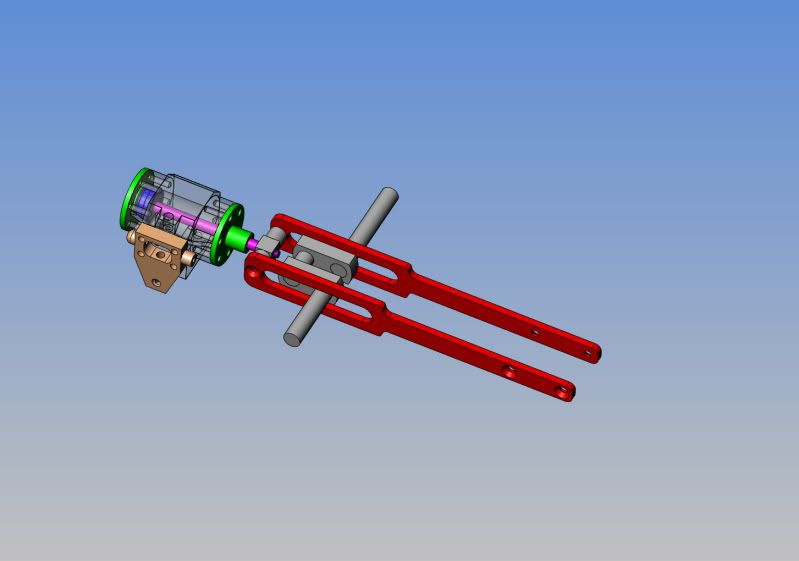

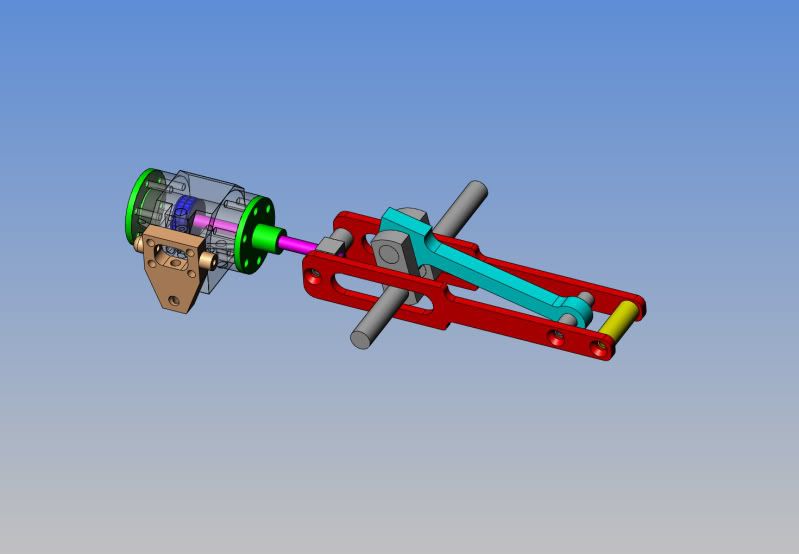

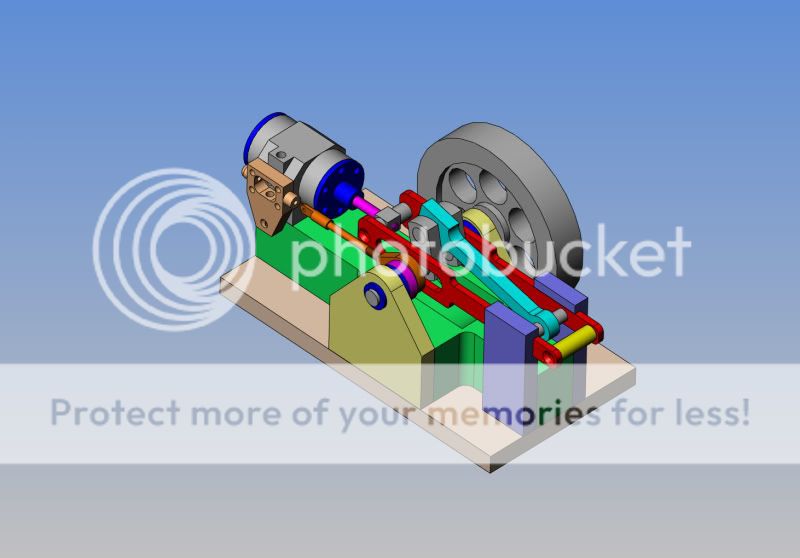

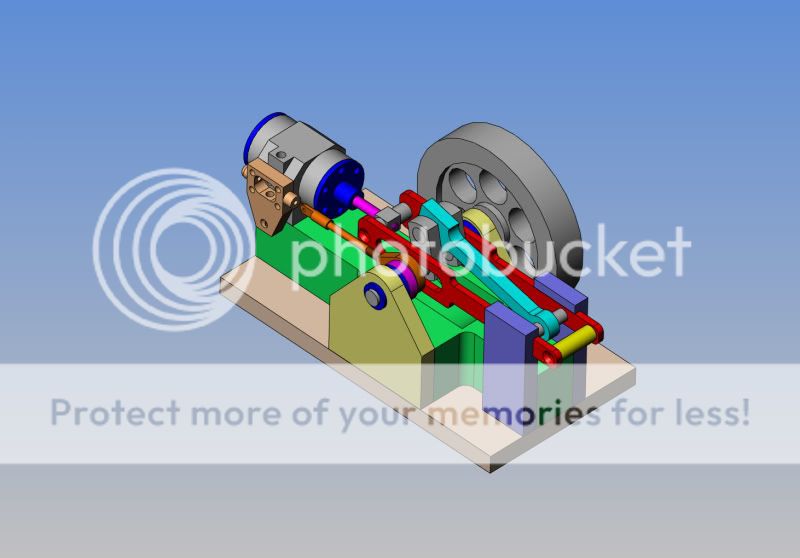

Job is on temporary hold again. Thats okay---I have sussed out the overcrank guides and the connecting rod. It all works well and everything clears okay. if you click on the top picture you will see an animated video of it working. I just spent 20 minutes talking to my Solidworks provider figuring out how to make an animated video that lasted longer than 10 seconds.

This is about 90 percent of the finished design. I have to add the appropriate fastener holes and a bit around the valve body.

- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

Brian

That is a really good looking design! I was thinking of trying my hand at this one but my materials inventory is different from yours so I will probably have to make some minor alterations. You have put a lot of thought and work in this engine so before I got to much into it, I thought I should ask. How critical is the 3.438" OD on the flywheel? The most I can work out is 3.124" x 3/8" steel. Do you think that will work OK? Or should I plan on using two flywheel?

Jerry

Similar threads

- Replies

- 413

- Views

- 39K

- Replies

- 25

- Views

- 3K

- Replies

- 6

- Views

- 3K

- Replies

- 61

- Views

- 8K