Cogsy

Well-Known Member

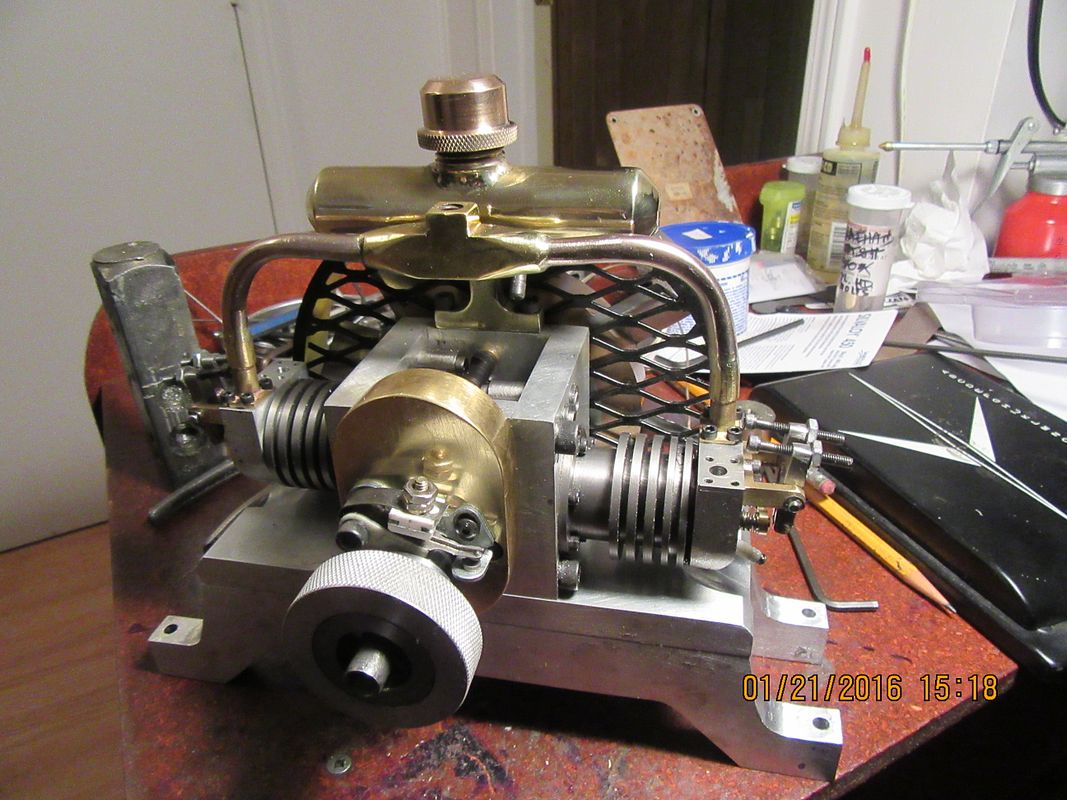

Looking mighty fine but I think the stacks need their angle cuts.

I agree Cogsy--I won't cut them though until I get the intake system sorted out and installed, because the intake system is going to visually have some effect on just how long the stacks should be.Looking mighty fine but I think the stacks need their angle cuts.

I don't really buy this bit about the condenser giving a stronger spark, but I have been wrong before.

I'm not sure about the mild steel mounting bracket having any effect on the magnetic field either, but I will make one up to see if it makes a difference.

I am basing my negatives on the fact that when you hook up a 12 volt automotive coil as I have this dual output coil,

Enter your email address to join: