- Joined

- Feb 17, 2014

- Messages

- 41

- Reaction score

- 6

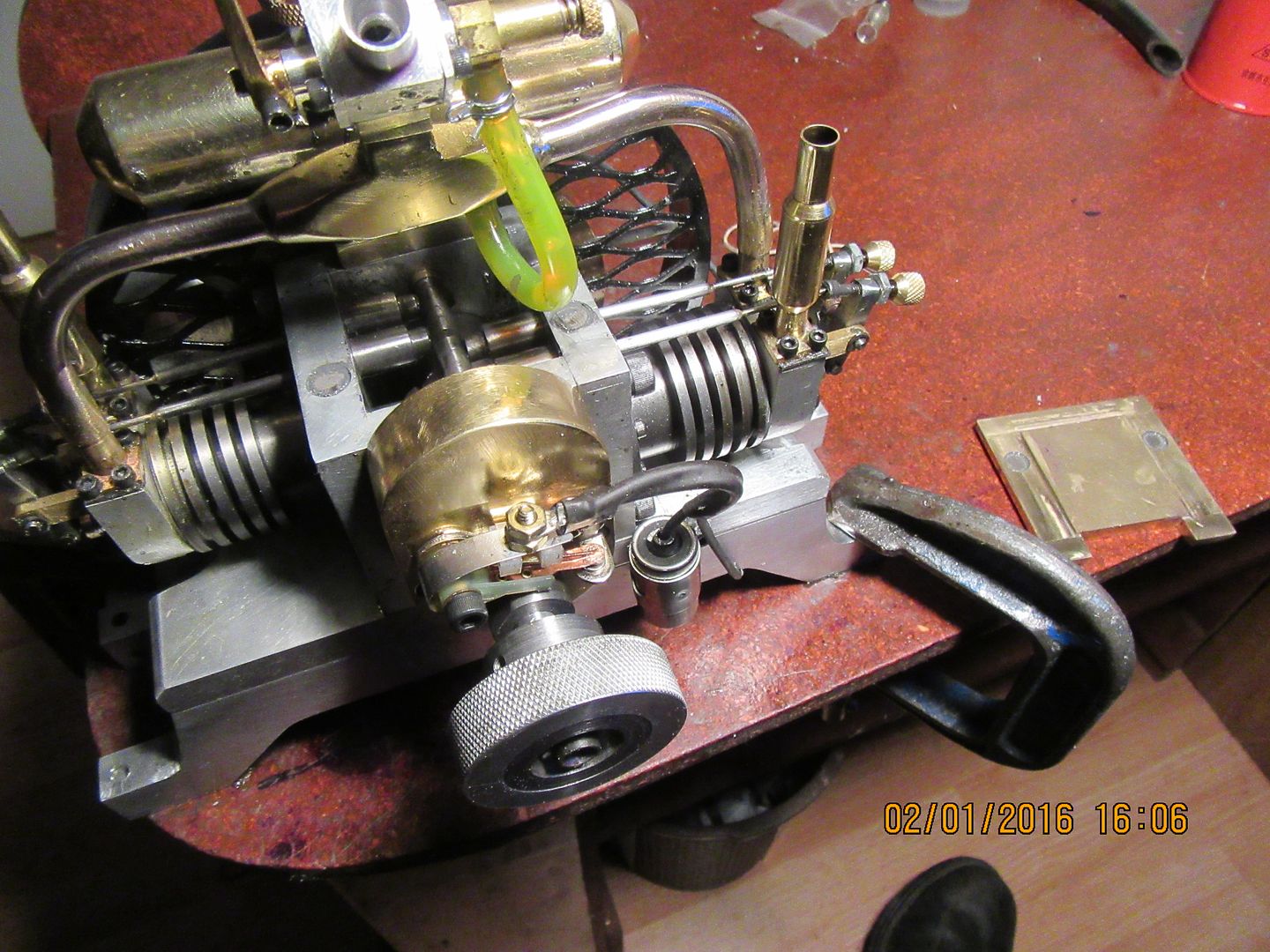

Congratulations, that sounds just like it should and clearly this thing wants to run, start was so easy

e. I might need three men and a bulldog to get it off to oil the engine with my squirt-can.--- J.B. Weld takes a terribly long time to "set up", at least 24 hours, so I won't know until then if I have the magnets in the right way or not.

It runs 10 to 12 minutes on the amount of fuel in the tank.Beautiful easy runner!Thm: Enjoyed the video. What kind of "mileage" or run time does your fuel tank provide for your twin? ------Dave

Enter your email address to join: