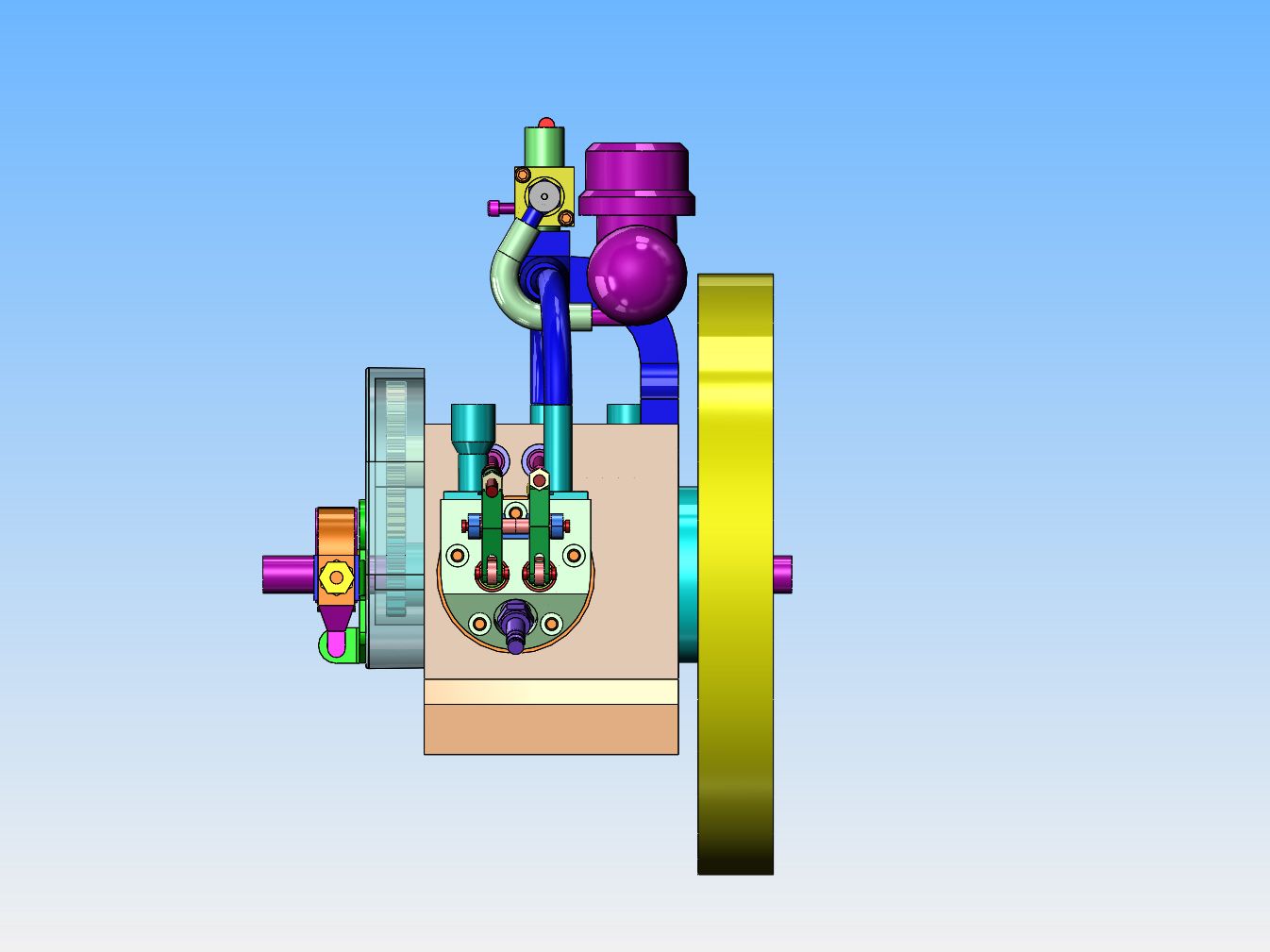

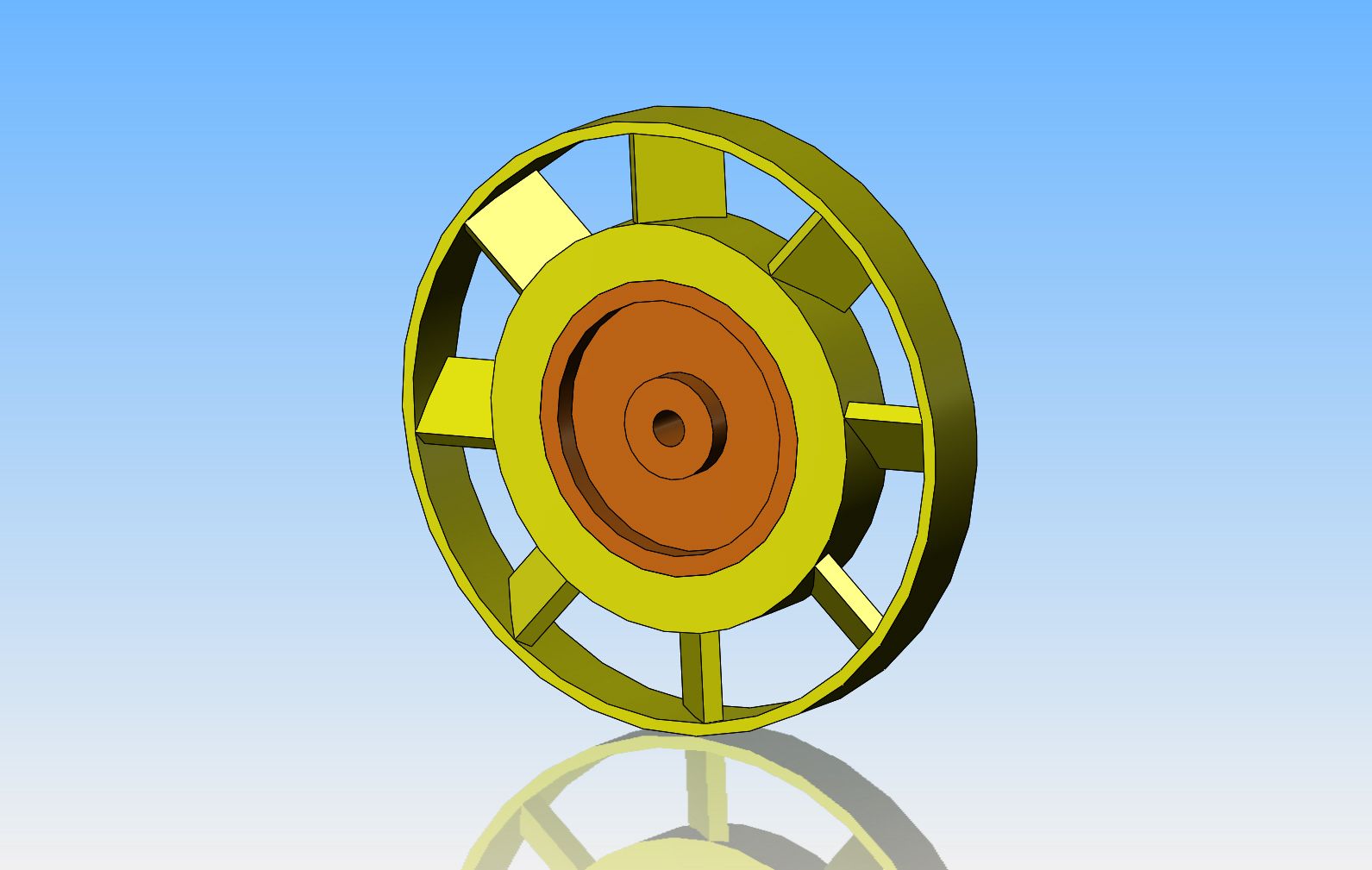

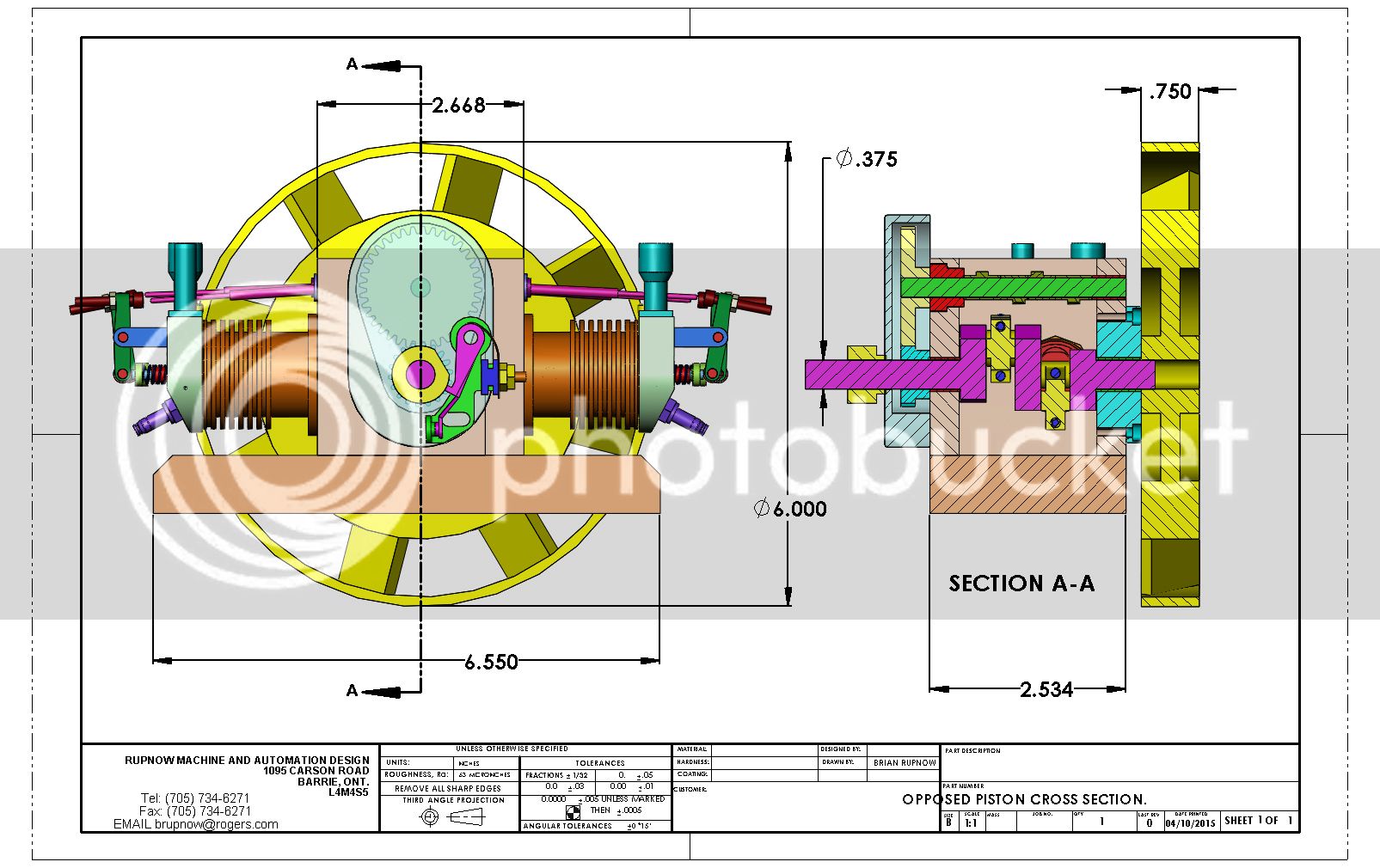

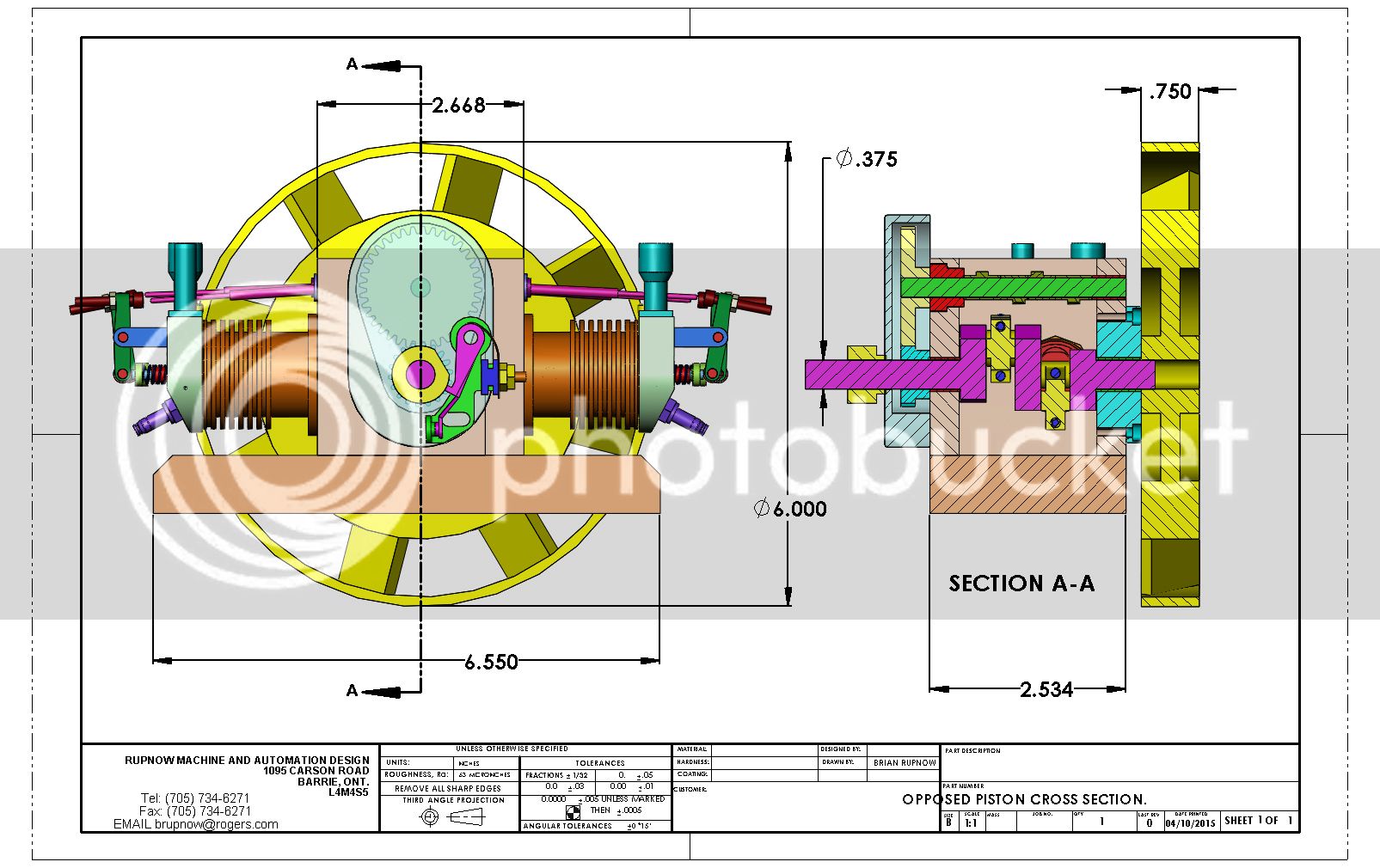

I resorted to a little hocus pocus when I designed the bushings for the crankshaft and camshaft. I wanted to be able to pull the crankshaft or the camshaft straight out of the engine without splitting those two main frame angles. So---I have a large "bushing insert" with the bushing pressed into it, bolted into a counterbore in the frame angle which supports the end of the crankshaft closest to the flywheel. If I remove the flywheel and the blue "bushing insert" the entire crankshaft should pull straight out through the side of the housing. I did something very similar at the opposite end of the camshaft, only there the bushing itself has a large enough outer diameter that by unbolting it and pulling it out, the whole assembled camshaft can be pulled out thru the side of the main frame.

Last edited: