Time to stop. It's not been a good night.

(But stay tuned...the story has a twist.)

Although I had some happy time making my first tool (cut-off blade from a hack saw) and using my grinder for the first time...I had crummy luck trying to thread a part with a die. It got worse when I switched to the mill.

Using my new dial test indicator to square my vise was a (frustrating) experience. After some time I got okay with it. (That or frustrated enough to think 'good enough').

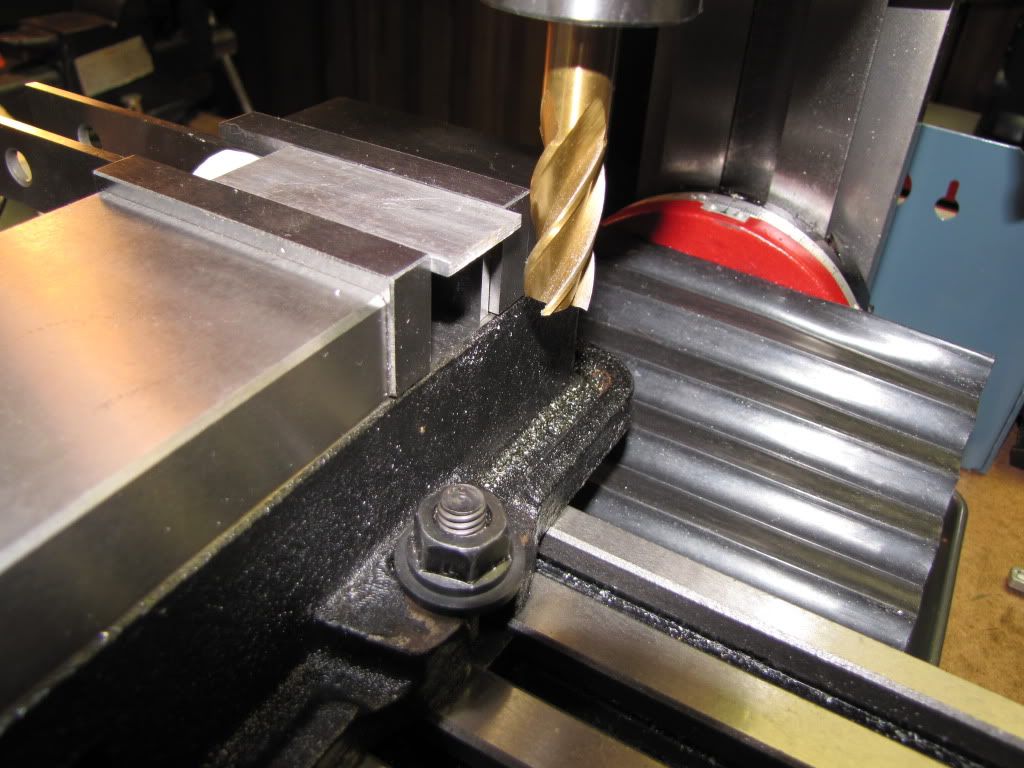

Then it came time to trim one edge of the engine base.

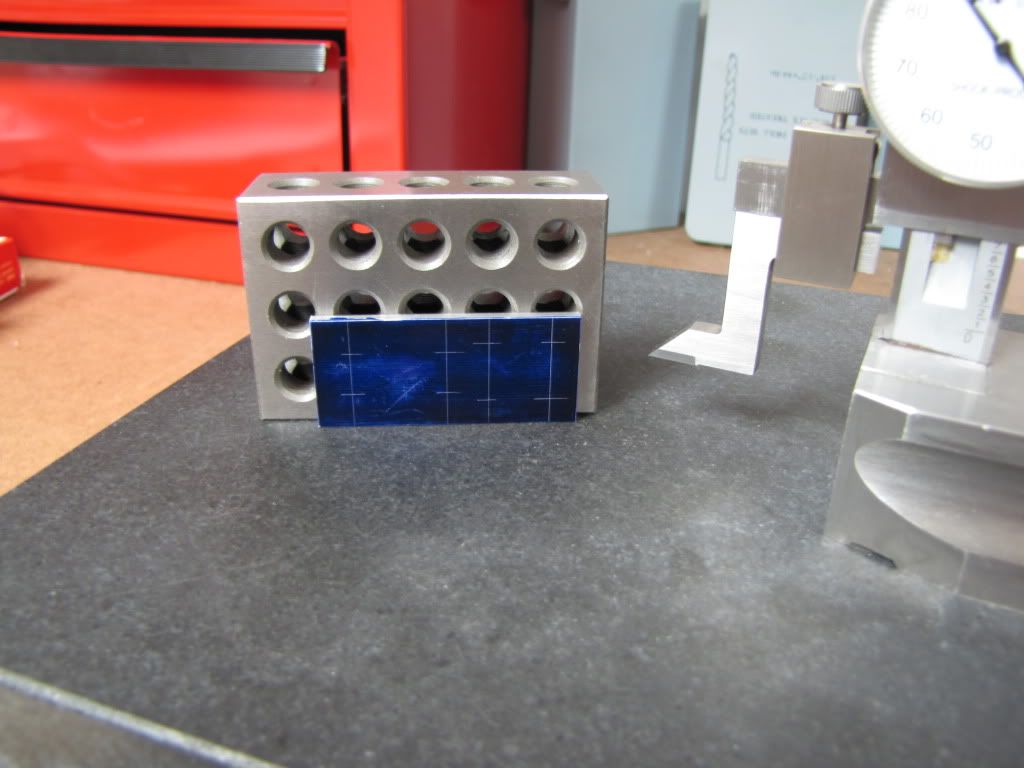

The setup. The white thing to the left is a peanut. Got that from 4156df.

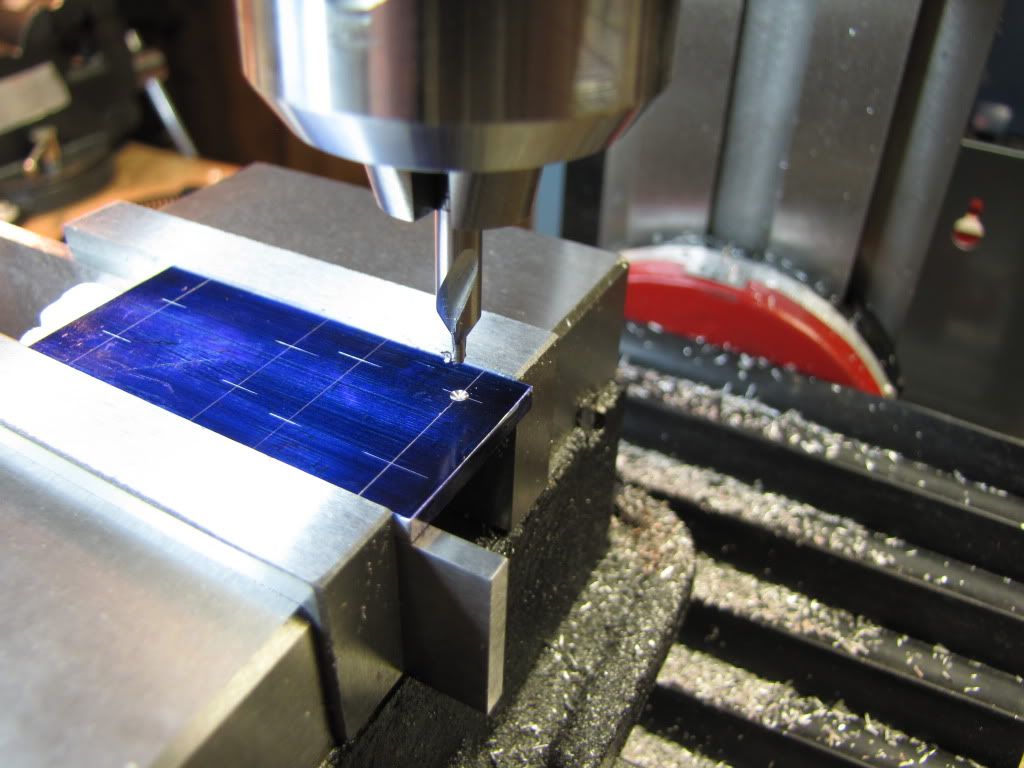

No vise stop and maybe that's part of the problem.

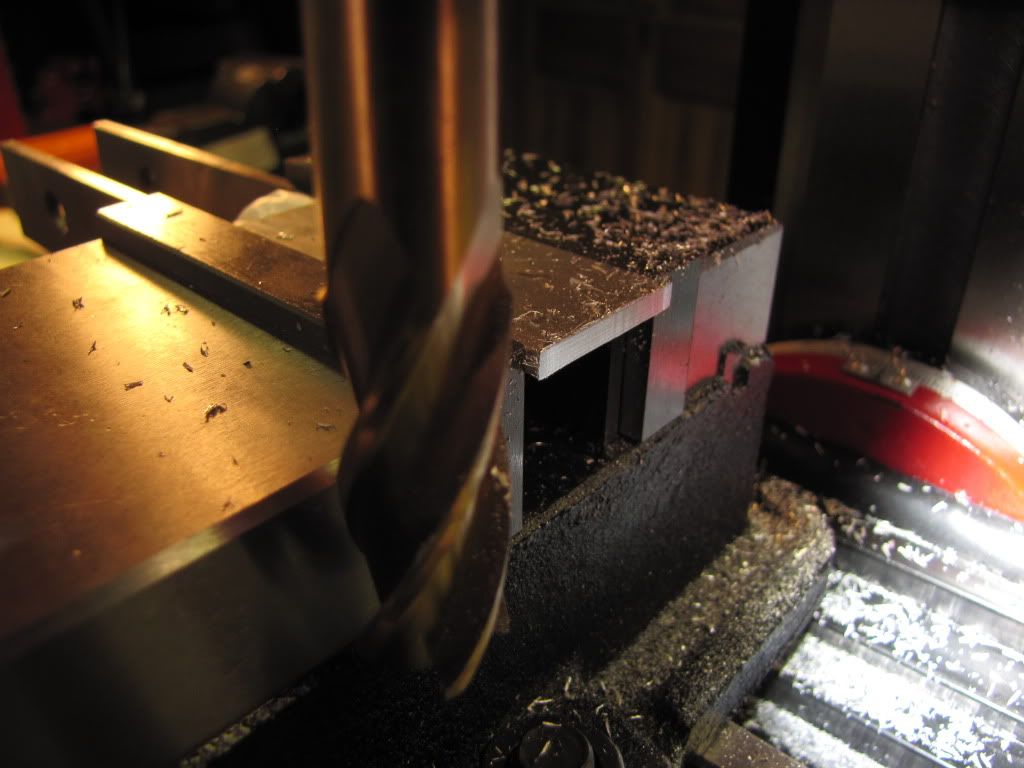

This is after cutting...

[Edit: Apparently my comments about climb/conventional milling were wrong. I'm removing them so as not confuse others who may follow. More likely, those that follow are more knowledgeable and I'll just end up continually embarrassing myself.]

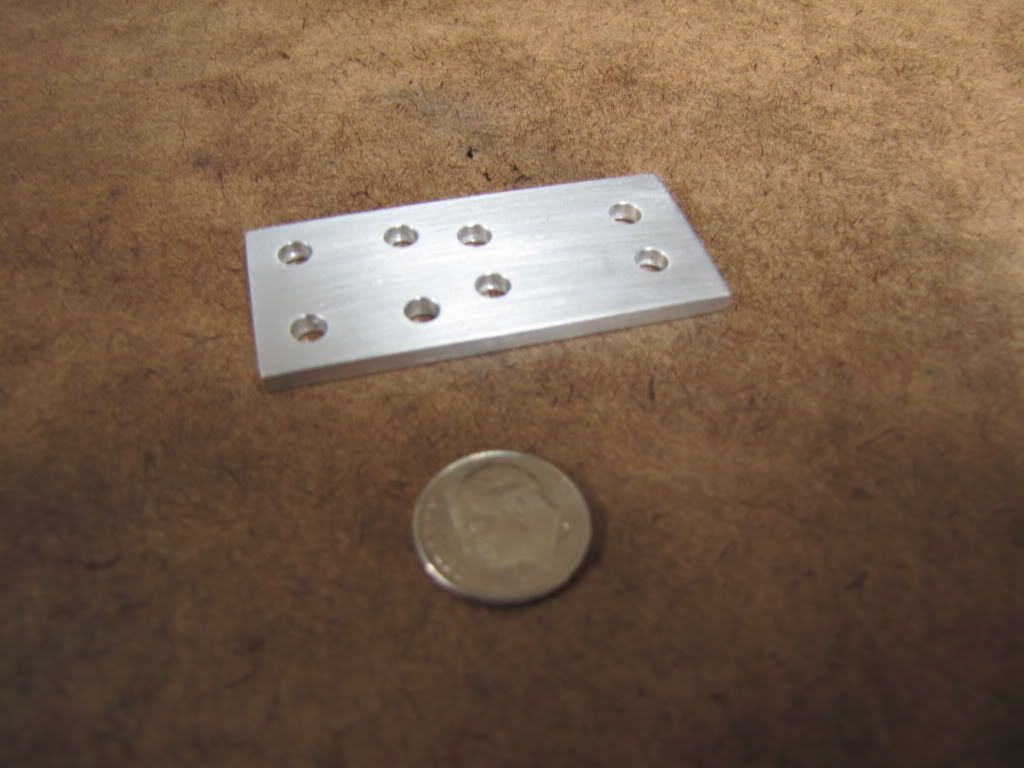

See the wavy edge?

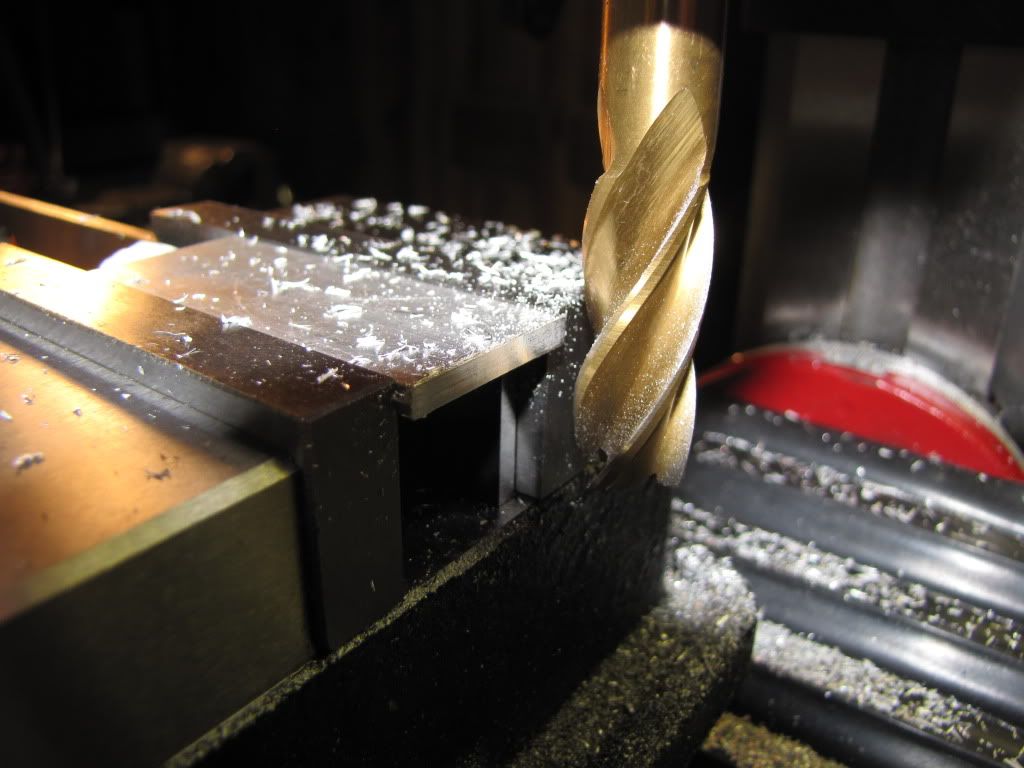

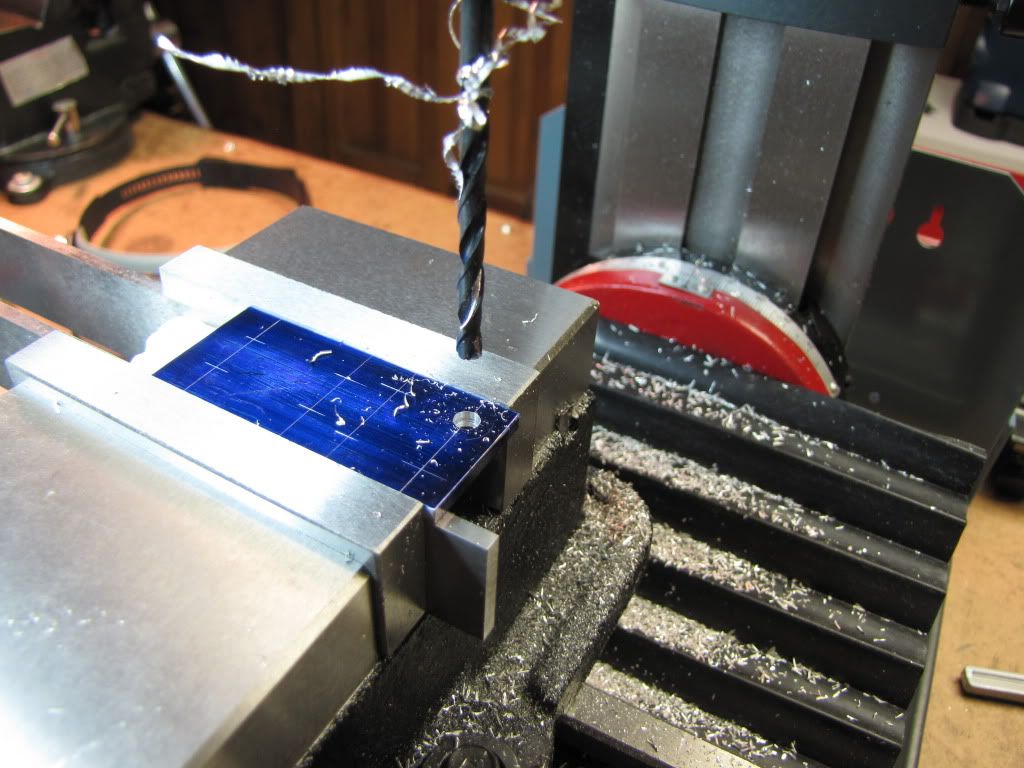

Then I wondered about the lock on the Y axis. I couldn't reach it because of the vise. So I went back. [Edit: Originally said X axis. The lock that affects the X axis is on the Y axis. Sorry.]

Duh. Used an Allen wrench and got to the lock. Locked down the X axis. Didn't even move the X axis - prayed there was some flex that would spring back.)

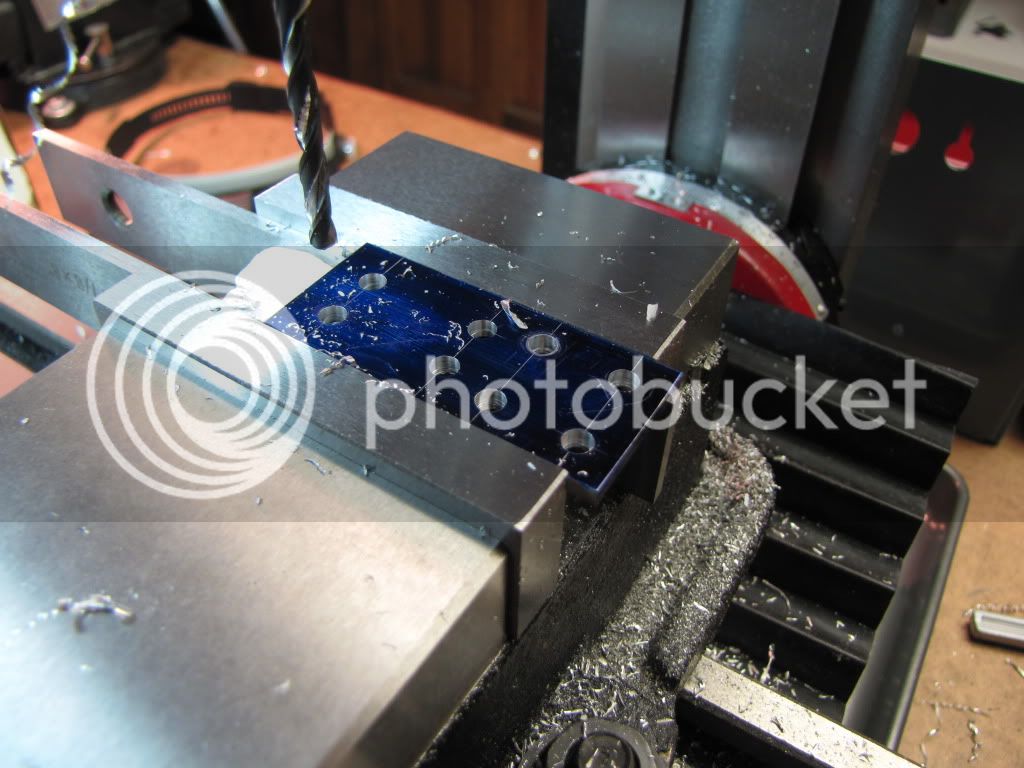

Result...

Seems pretty smooth to me.

[Edit: See where the part ended up? I'm told, and now believe, that's a conventional cut - shovel action. So I should be able to do still better with a final light climb cut. I'll experiment so more.]

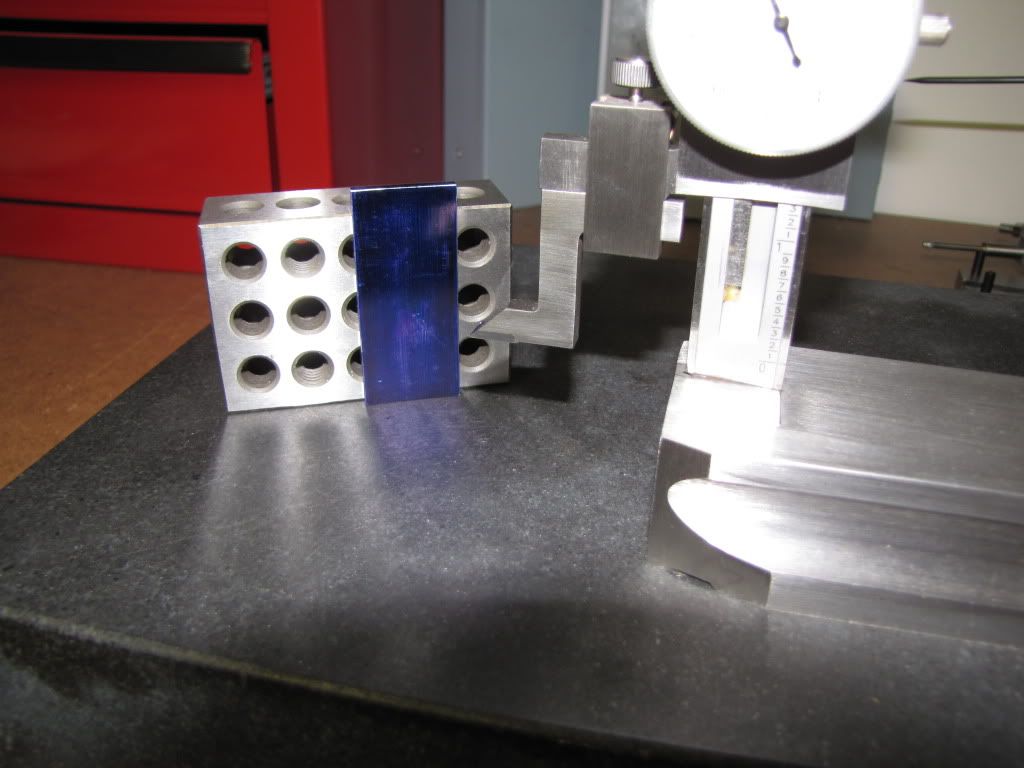

Back to happy guy (except for the thread fiasco [Edit: And now the mistakes I've in this post.]).

Stopping while I'm ahead [Edit: ahead? I think not.].

When I remove the part from the vise I'm supposed to file the edges to deburr. I'm thinking it won't look good - that is - not smooth. One thought is to hold the part and slide across sandpaper. Better but there might be a taper to it (one end deeper than the other). I know I don't want to use a deburr tool. Jumpy. Any suggestions? ???

Thanks! ;D