Brian,

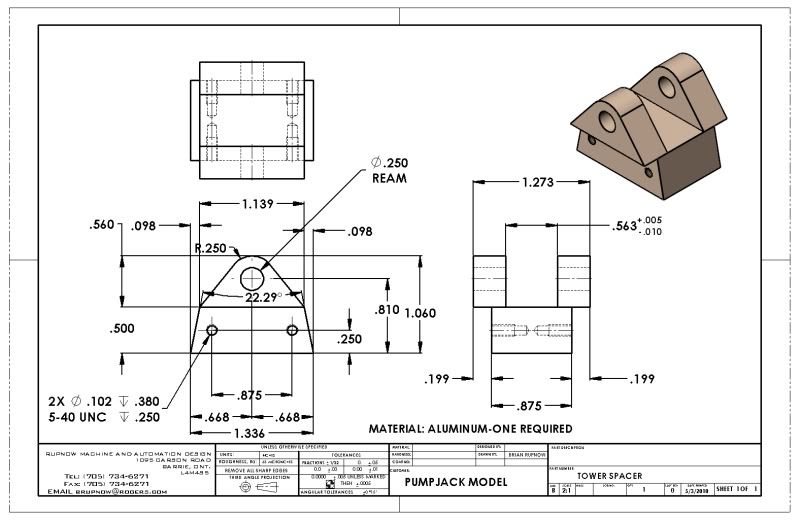

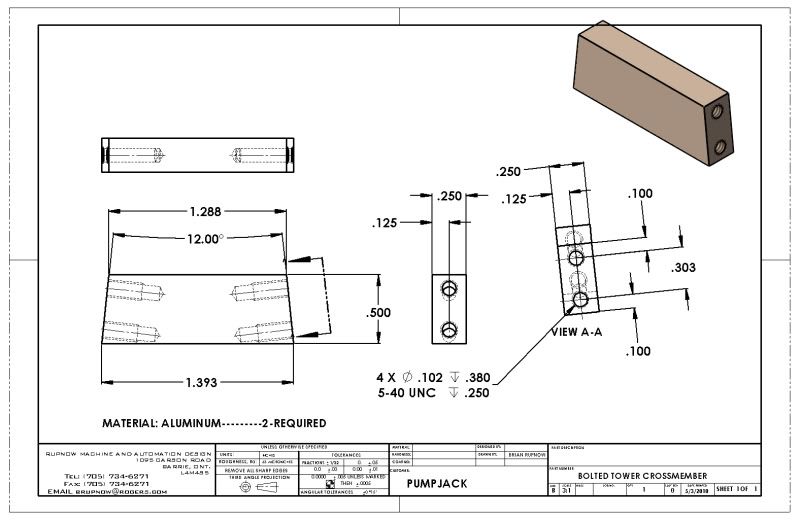

Very nice drawings indeed, and I am not nitpicking at all. Because your drawings show the correct dimensions with allowances made for the angles of the faces.

But some people can make a mistake sometimes by not showing the dimensions for the correct end to take your measurement from for machining the part, and because yours has both shown to perfection, I thought I would take the opportunity to explain a problem that can and does occur.

The part of your drawing shows a very good example, in that it has two different angles on it, both acute (from 0 to 90 degs) and obtuse (from 90 to 180 degs).

This can lead to a common mistake by machinists who are new to this game, and it isn't an obvious one, even though it would be obvious to many of us more experienced ones.

If you try to take an edge finder reading from the obtuse end (larger than 90 degs), your dimensions will be incorrect when you come to drill the holes, as your edge finder will be picking up the face lower than the corner rather than exactly on the corner, which would not happen if you used the acute end.

How do I know this? I can still remember the clip around the ear from my instructor over 40 years ago. They could use corporal punishment in those days.

Just to try to explain, I have shown a red arrow pointing to the acute angled end, which should be used for taking your measurements from.

Bogs