michaelj199

Active Member

- Joined

- Aug 27, 2011

- Messages

- 26

- Reaction score

- 13

i believe the effective volume of the crank case will stay the same. while one piston is going up another is going down. the crank case pressure will only get as high as boost pressure and cylinder pressure will always be greater then or equal to boost pressure. therefor there should not be much if any air/fuel pushed up past the rings. there is only one point in time that the crank pressure could be higher then cylinder pressure and that's with the exhaust valve open right before the intake port is uncovered but that would be for only a very short period. with this V8 design and an open crank case ( not divided) there will always be an intake port open to the intake valley. so pressure increases caused by blow by of the rings will vent back into the intake valley. so there's no reason the crank case should become excessively pressurized.

i plan on running around 6-7 psi. this is a calculated figure so most likely closer to 5psi. my initial compression ratio is ~8 to 1 and after boost my effective compression ratio will be around 9 to 1. i plan on using brass chim stock for head gaskets so i can adjust compression ratio at will. timing can be controlled by the heat of the plug. i will start out with a medium and work from there.

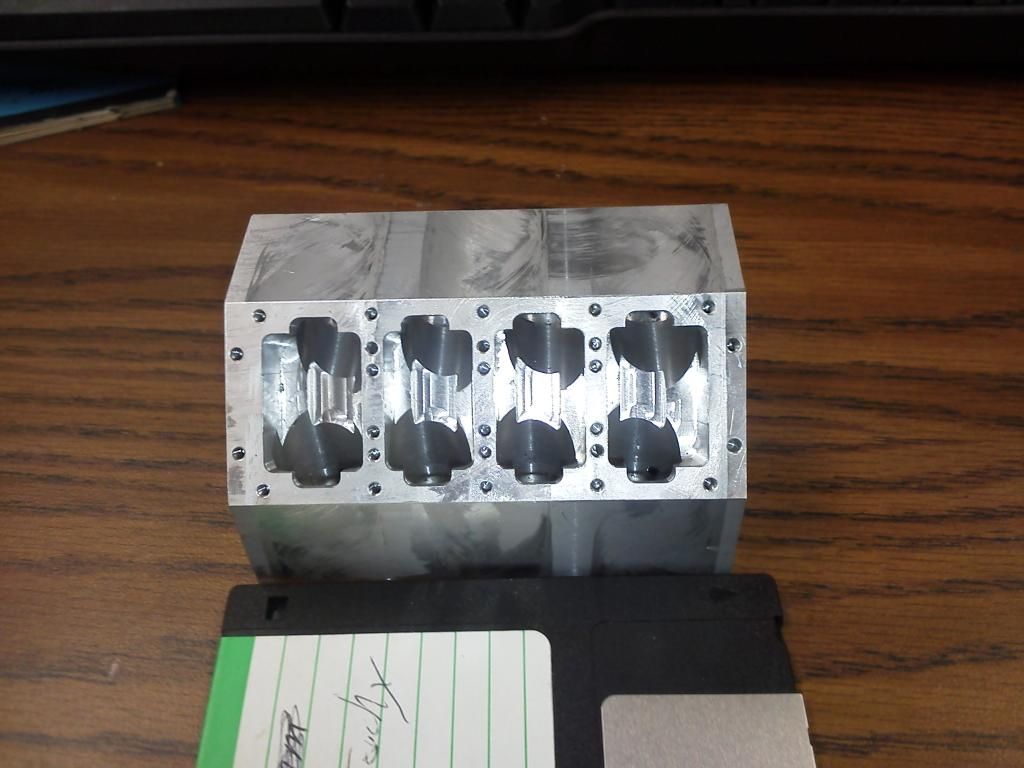

~.78ci engine

~.88ci per rev supercharger

1.25 overdrive on pulleys

=~6-7 psi boost

i plan on running around 6-7 psi. this is a calculated figure so most likely closer to 5psi. my initial compression ratio is ~8 to 1 and after boost my effective compression ratio will be around 9 to 1. i plan on using brass chim stock for head gaskets so i can adjust compression ratio at will. timing can be controlled by the heat of the plug. i will start out with a medium and work from there.

~.78ci engine

~.88ci per rev supercharger

1.25 overdrive on pulleys

=~6-7 psi boost