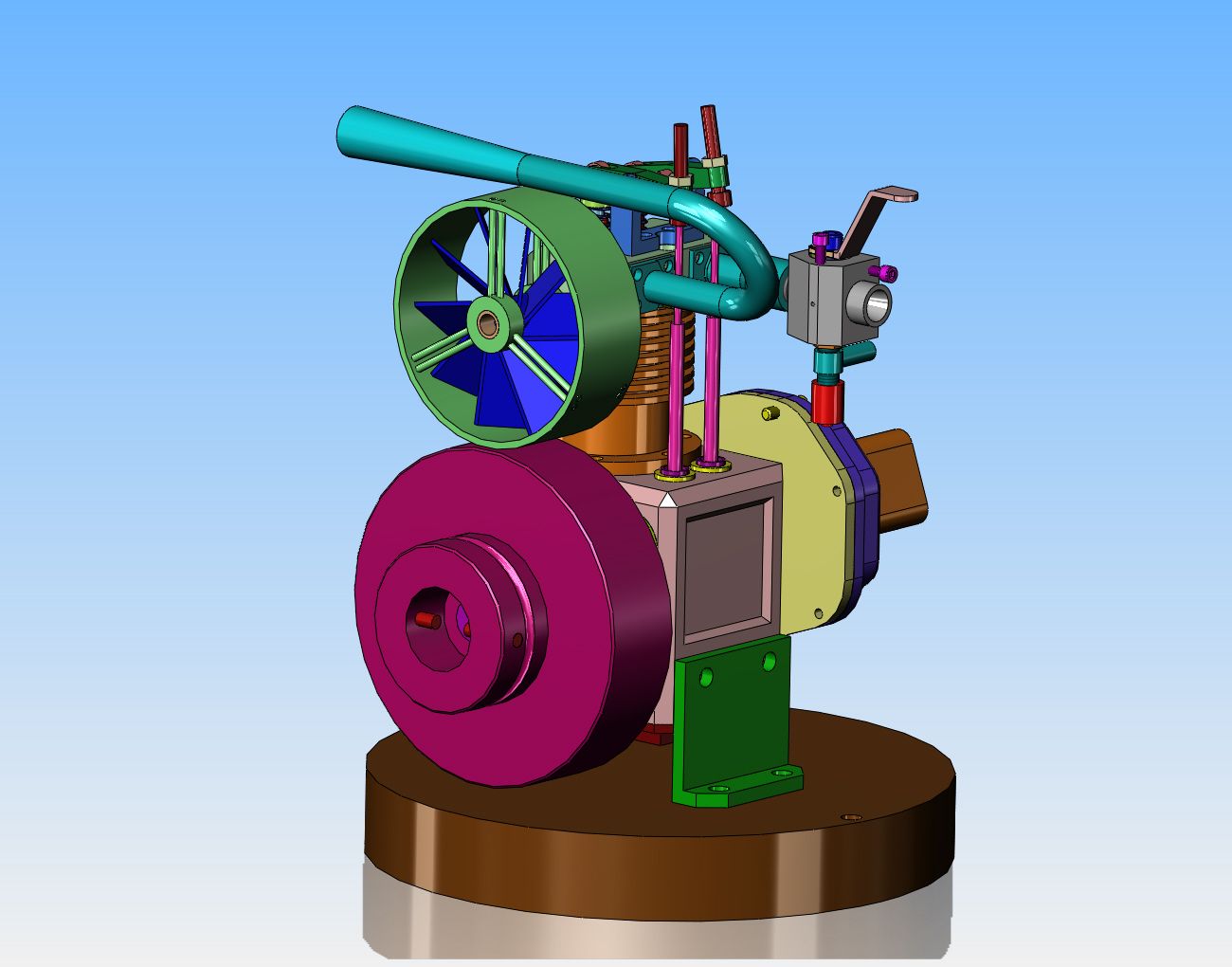

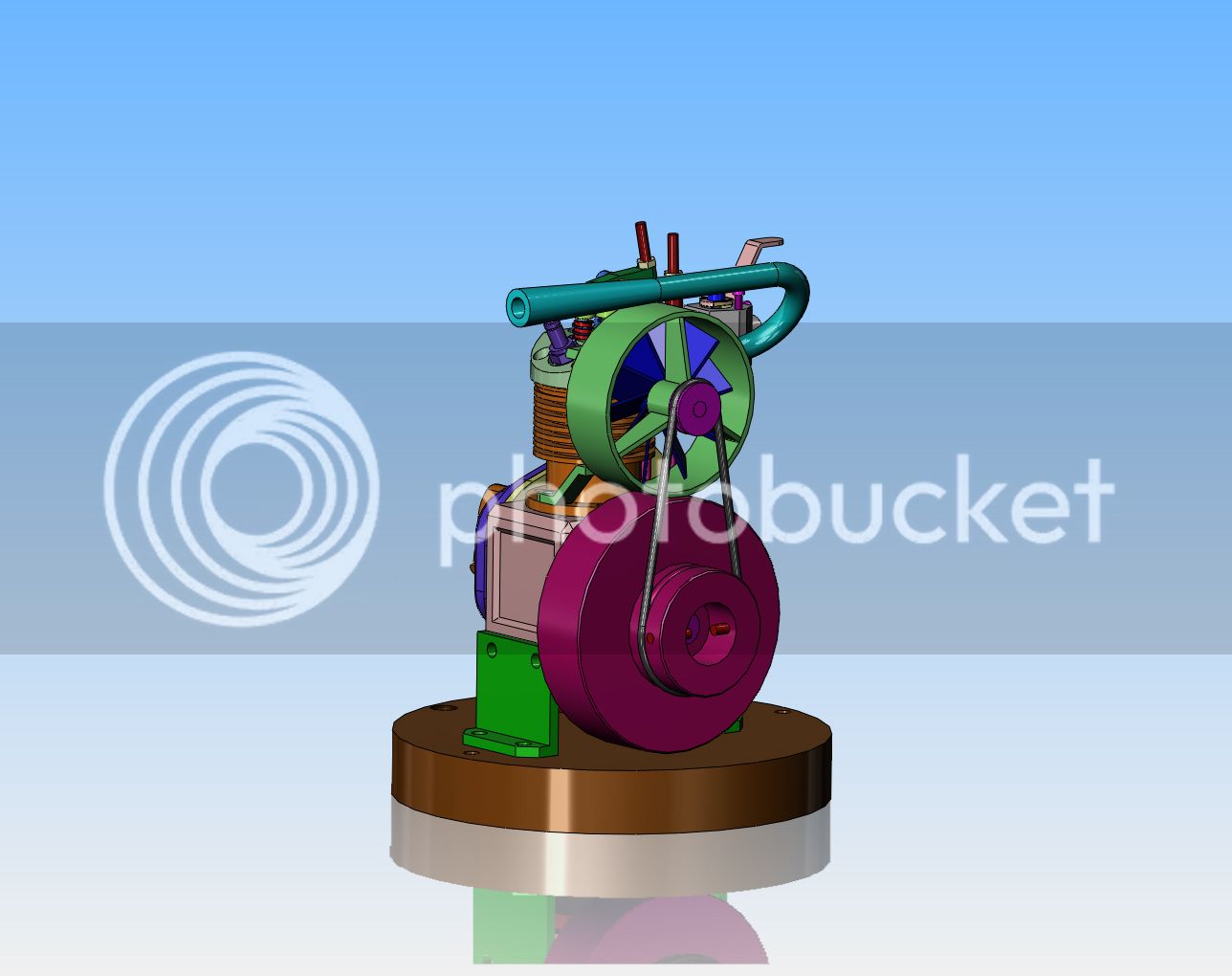

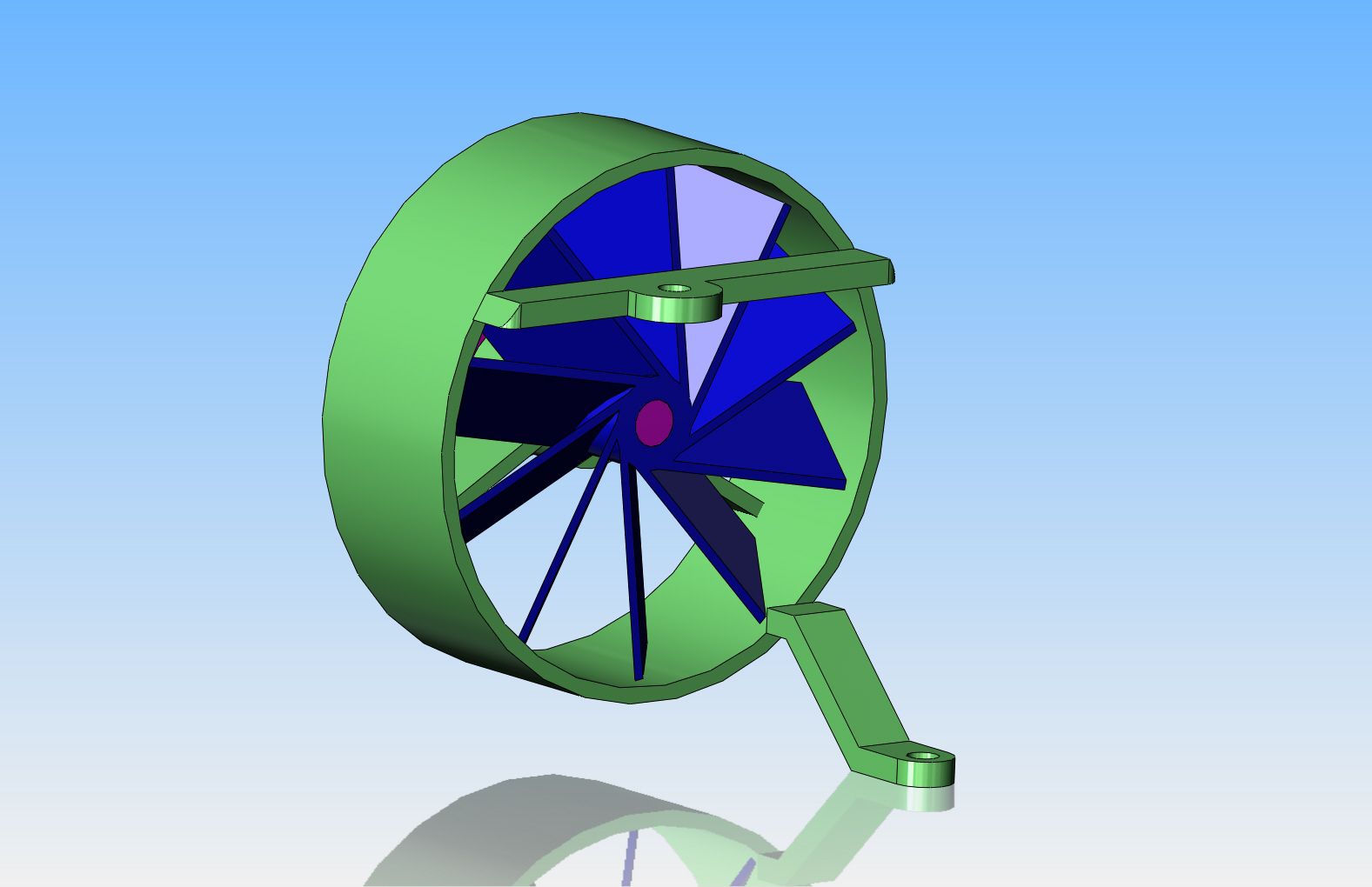

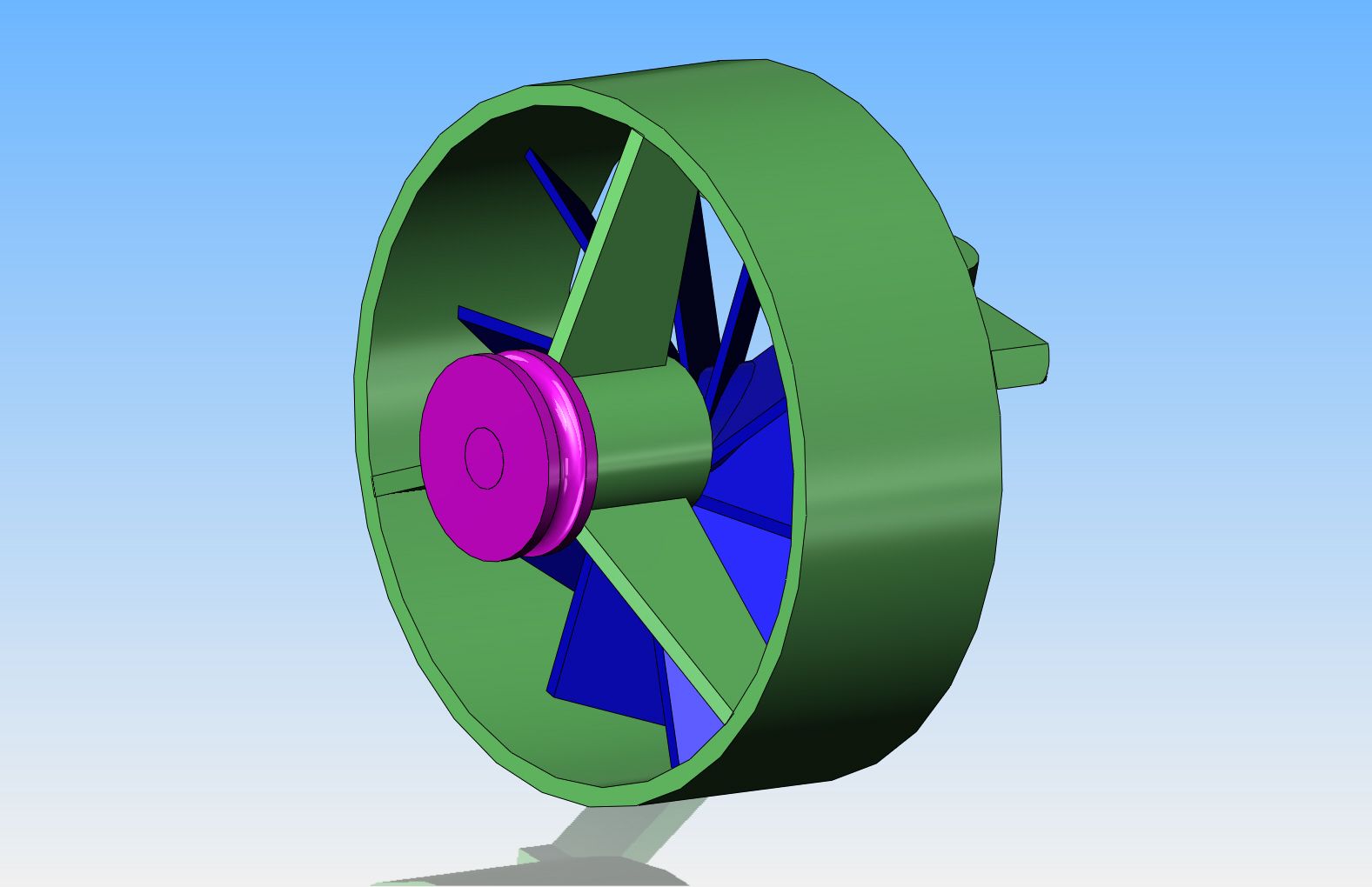

After much searching, I found a fan at Acklands-Grainger, aluminum, 10 blades, 2" diameter, small hub bored for 3/16" shaft. Its about 21 down from the top of the attached link. The store in Barrie was able to bring it in for me, but its going to take about a week. That's fine by me---I don't feel like any more machining right now anyways, at least for a while. The engine is running excellently, and I'm not going to mess with it for a week. I did download 9 pages of information on making piston rings that Steamer had posted as a pdf file. The cylinder now has such a high polish inside from running the Viton ring that I may just build a water cooled cylinder and a new piston, and play with that until I can make a set of rings that will really seal.

http://www.grainger.com/category/fan-blades-and-propellers/hvac-and-refrigeration/ecatalog/N-jr8Zh9e

http://www.grainger.com/category/fan-blades-and-propellers/hvac-and-refrigeration/ecatalog/N-jr8Zh9e