You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

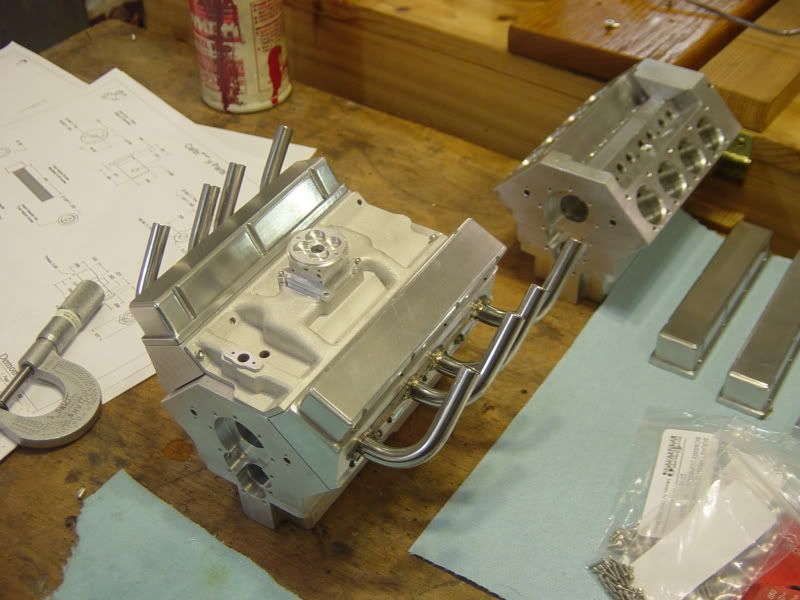

My start to Steve's V8

- Thread starter bob shutt

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

ukmachinist

New Member

- Joined

- Jan 4, 2012

- Messages

- 4

- Reaction score

- 0

Great v8 were can i purchase plans from?

Robby

Robby

Looks good. How did you make the half inch radius on the end?

Looks like a great start.

- Joined

- Jul 16, 2007

- Messages

- 2,987

- Reaction score

- 1,056

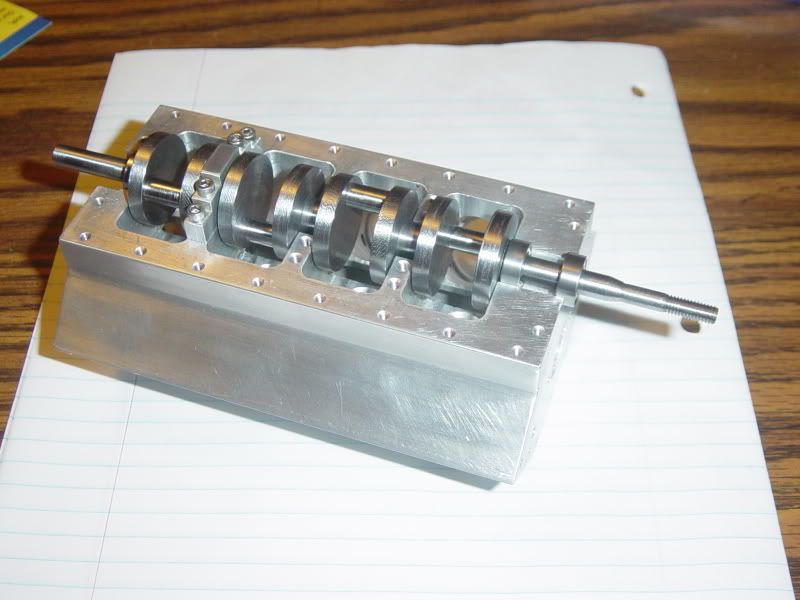

It looks like the turning part on the throw is coming out fine but I have found that by using a bifurcated tip on your tool lessens the load and prevents it from chattering, although I was reaching much deeper than you are. It looks like its coming along very nicely.

gbritnell

gbritnell

Your home free now. That was the worst part and now it's behind you.

- Joined

- Jul 16, 2007

- Messages

- 2,987

- Reaction score

- 1,056

The crank looks great Bob. Like Steve said this is probably the most challenging piece to make. Although it looks simple compared to a cylinder head the chances for a catastrophe are just waiting to happen.

gbritnell

gbritnell

I have about 8 to 10 hrs in the crank. 5 or 6 on saturday and about 4 on sunday. It was very nerve racking when the supports fell out. I ended up taping them in place to get thru the cuts. This whole project is going pretty good.

Similar threads

- Replies

- 1

- Views

- 673