zeusrekning

Well-Known Member

- Joined

- Dec 21, 2007

- Messages

- 448

- Reaction score

- 0

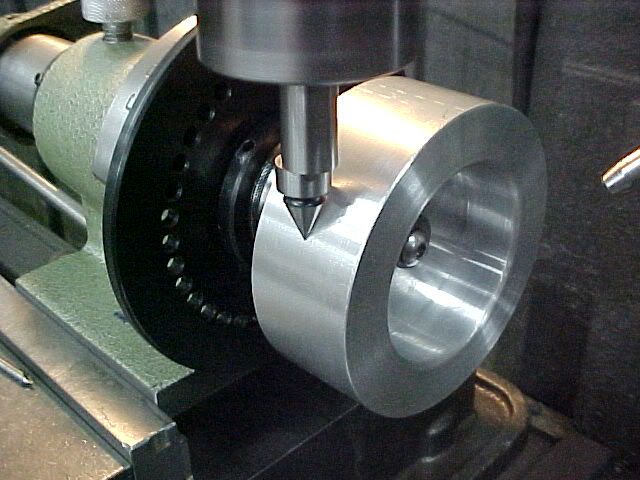

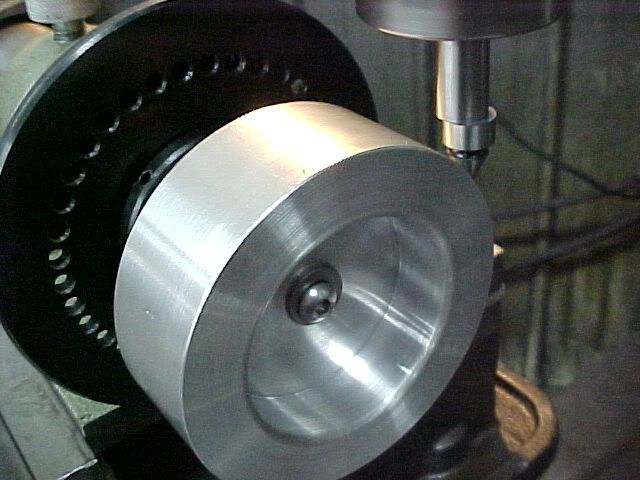

I finished my transistorized ignition a few weeks ago and tried it out on an engine today. I picked up a small trimmer engine a couple weeks ago when Cedge and I were scrap yard hoping. I got the engine to halfway run this evening (high rpm needle seat is busted so no high rpm). I mounted my magnetic pick up and used the magnet in the flywheel. The switch is a magnetic switch from McMaster (used on machines to recognize the door is closed). Not sure if it is considered a hall effect switch or a "reed switch".

Anyways, comparing how the engine ran with the stock ignition versus the new one, it ran a lot better. It started with one light pull of the pull starter, ran up to a slightly higher RPM (judging by sound) and it did not shut down at wide open throttle. With the original ignition it would shut down because of too much fuel when it tried to reach high RPM (I think).

I had to let someone know it worked :big:

Side note: I had my wife come out and watch the initial firing. I had the spark plug out trying to see where TDC was so I could mount my switch. The switch turns on the ignition and when the magnet is removed the plug fires. I came into contact with the spark plug. It lit me up very well. Made the elbows hurt

I hope to try it soon an a different engine to see if it works at high RPM. ALSO thanks to Swede for the help he gave me on this project.

Tim

Anyways, comparing how the engine ran with the stock ignition versus the new one, it ran a lot better. It started with one light pull of the pull starter, ran up to a slightly higher RPM (judging by sound) and it did not shut down at wide open throttle. With the original ignition it would shut down because of too much fuel when it tried to reach high RPM (I think).

I had to let someone know it worked :big:

Side note: I had my wife come out and watch the initial firing. I had the spark plug out trying to see where TDC was so I could mount my switch. The switch turns on the ignition and when the magnet is removed the plug fires. I came into contact with the spark plug. It lit me up very well. Made the elbows hurt

I hope to try it soon an a different engine to see if it works at high RPM. ALSO thanks to Swede for the help he gave me on this project.

Tim