spedding84

Member

- Joined

- Jan 1, 2011

- Messages

- 6

- Reaction score

- 0

So last week after owning my mini-lathe for over a year I cleaned off the grease and turned a small finger ring out of stainless. Man did that put a bug in me. So this weekend a friend let me use his machine shop to start my first engine. It's a simple wobbler I got from these plans: http://people.wku.edu/andrew.ayre462/Wobbler_Design.pdf.

I know it is very simple compared to some projects on this site, but I have already learned some useful machining skills from this project. The owner of the shop was very helpful and showed me alot. Here are some pics of what I have done so far...

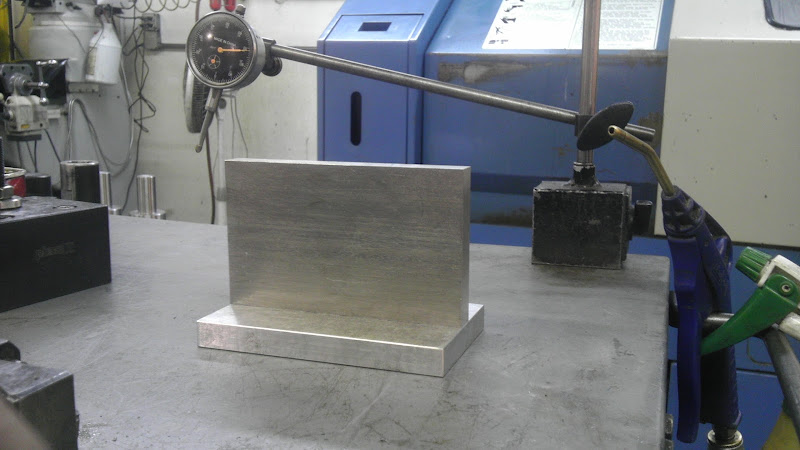

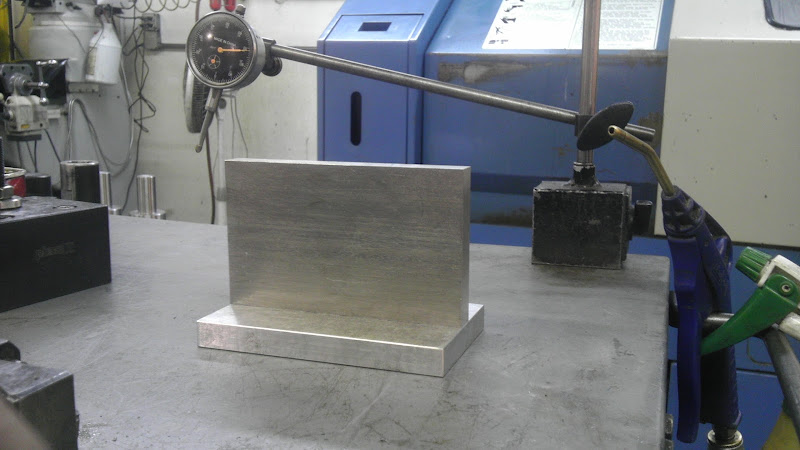

Truing the base and upright to 3" x 5":

Finding the edge, a neat process:

Drilling the holes to secure the upright:

Tapping the upright holes with a tap handle and center finder:

What I accomplished so far:

Next week I will drill the holes in the upright at his shop. Then, I will turn the crank, flywheel, etc. I hope to do this on my mini-lathe so I can do it at home because the shop is a hour away in North Atlanta near my job.

Stay tuned....

I know it is very simple compared to some projects on this site, but I have already learned some useful machining skills from this project. The owner of the shop was very helpful and showed me alot. Here are some pics of what I have done so far...

Truing the base and upright to 3" x 5":

Finding the edge, a neat process:

Drilling the holes to secure the upright:

Tapping the upright holes with a tap handle and center finder:

What I accomplished so far:

Next week I will drill the holes in the upright at his shop. Then, I will turn the crank, flywheel, etc. I hope to do this on my mini-lathe so I can do it at home because the shop is a hour away in North Atlanta near my job.

Stay tuned....