Wow. I'm in awe.

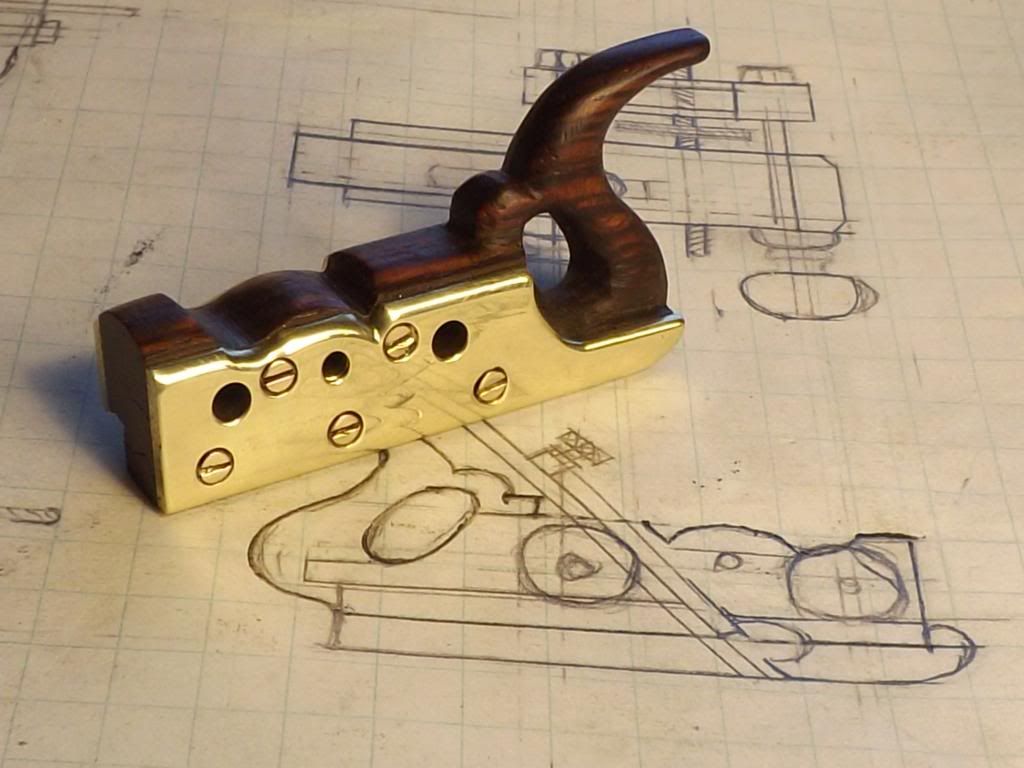

I hesitate to voice any suggestion, since that level of work is far beyond me, but one thing I see that detracts from the tools is that the sharp edges and corners have been polished away. Polishing without rounding over edges is very difficult, so it's not surprising. The book "Gunsmith Kinks #1" from www.brownells.com has a good discussion of polishing.

I hesitate to voice any suggestion, since that level of work is far beyond me, but one thing I see that detracts from the tools is that the sharp edges and corners have been polished away. Polishing without rounding over edges is very difficult, so it's not surprising. The book "Gunsmith Kinks #1" from www.brownells.com has a good discussion of polishing.