Other Gus,

Yes I will get it running, sooner or later, probably next in line. I now have to concentrate on Lil Henry. Have you got anything new planned after you get the Rupnow engine hitting and missing?

Chuck,

The bearing surfaces held up pretty good, crocus cloth, should be all they need. I've already decided to abandon the enclosed bearings and go with bronze. First factor is the metric sizes and second is cost, (more important to my deep pockets, my free time is free). The crank is a concern, I'm hoping I can get it run true. The throw is trapped inside the connecting rod, which means I will have to reassemble with the rod and bearing in place. Not the best situation. Worst case, I'll make a new conn rod and crankshaft.

Thanks Phil,

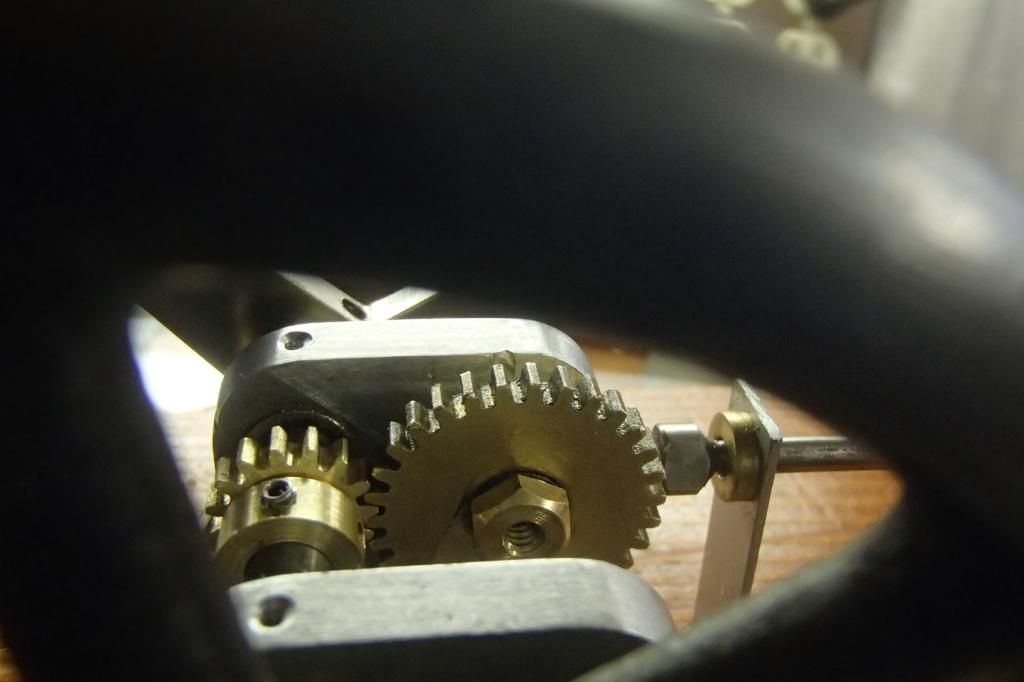

The cutters have the gear tooth range marked on them. I don't anticipate any problems. I opened the package, looked at one of them and set them back on the my work bench.

After the Lil' Henry project stalled, I worked on a few other things, the William for one and started making improvements on my Wyvern.

At this point I proudly can say it is finally a finished project.woohoo1

In the past couple months I've managed to evict the little devil that resides in a lot of the engines we amateurs build.

I'm walking on clouds, it's running great. I spent most of yesterday looking and grinning while it ran for almost 6 hours, only stopping when I fiddled with the fuel mix trying to get it to run consistently somewhere in the 300 rpm range, 430 was it's best. It will run for hours like that.

In my somewhat less than humble opinion, that ain't bad.

You should see it soon in the Finished Projects forum and you can bet I'll bring it to CF, if I don't wear it out by then.

Today if, I can manage to stay away from it, I'll try my hand at the gear for Lil' Henry, maybe.

GUS