You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

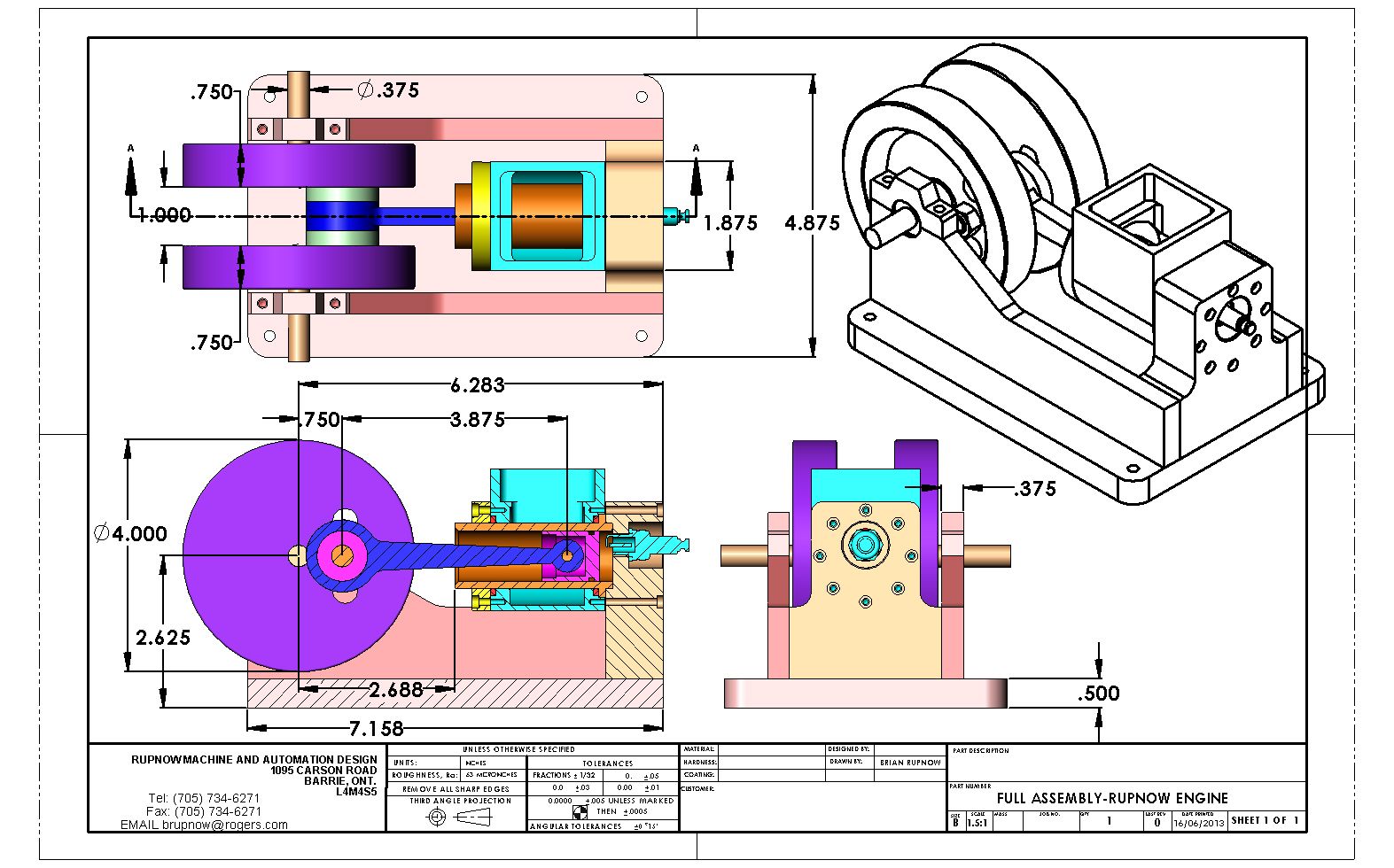

I may design an I.C. engine---

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Cogsy

Well-Known Member

Looking great so far. No need to worry about me starting before you get the design tweaked - my idea of soon and yours are vastly different. I have to finish my 2 Upshurs first, and the way they're going it'll be another few months yet...

4 inch looks doable on my 7X lathe, in fact probably just as easy as 3.5, but I doubt 7 or even 6 inch would be possible.

Looks like I'll have to research cutting bevel gears next .

.

Keep up the good work!

4 inch looks doable on my 7X lathe, in fact probably just as easy as 3.5, but I doubt 7 or even 6 inch would be possible.

Looks like I'll have to research cutting bevel gears next

Keep up the good work!

Well, it looks like this is going to be an all ball bearing show. I called Canadian Bearings today, and a 3/8" i.d. ball bearing is only $4.98, so I ordered 3 of them, one for the big end of the con rod and two for the crankshaft bearings.. The only bushing will be in the small end of the con rod, and MAYBE (I'm not sure yet) in the governor stem-post.

Yes, but not too much. As soon as I got back from my ill fated holiday I stepped in a big pile of engineering work for one of my current customers and haven't had much time today. The valves in the Webster and the Kerzel are both 1/4" heads with .093" stems. I find that size very difficult to work with. Those engines have 7/8" and 3/4" bores, respectively. The Atkinson and the Odds and Ends are both 1" bores, and both have 3/8" valves with 4MM and 1/8" stems which are a heck of a lot easier to work with. I don't really know if a 3/8" valve would be over-carbureting my engine or not. That may be a "Suck it and see" answer. I will be using valve cages with them, and the valves will exit thru the "cylinder head", similar to the Kerzel design, with the intake valve being atmospheric and the exhaust valve actuated by a rocker arm. My next real step is going to be exploring the arcane science of a vertically aligned governor and how to tie it into the valve train. One of the chaps who built my sawmill and posts regularly on the other forum I post on has sent me some pictures of a governor set up like this, but I haven't had time to study on it too much. The gears will be 24DP because that is the size of cutters I have, and they will be 1/4" wide because I have a bunch of 1/4" brass plate, but I haven't thought about diameters yet.--Of course it will be the conventional 2:1 ratio.--Brian

Someone on another forum has asked why I didn't use needle bearings, because they are much smaller than a ball bearing and would be easier to fit into a small engine. My answer is as follows: There's a little trick to needle bearings that a lot of people aren't aware of.--The friggin' things don't come with an inner race. You can't run them on a plain old cold rolled shaft, because they just chew it up, ruining both the needle bearing and the shaft. They are meant to run only on hardened shafts. You can buy the inner race as a separate part, but then the needle bearing has to be proportionally larger to account for the diameter of the inner race. I checked with the bearing folks yesterday before ordering the ball bearings. A needle bearing to fit a 3/8" shaft was 9/16" o.d. However, if you bought an inner race to fit a 3/8" shaft, then the needle bearing jumped to 3/4" o.d. and cost $17 for one inner race and needle bearing. A ball bearing is only 1/8" larger than that, at 7/8" o.d. and costs less than $5 per bearing. An additional factor is that size for size, needle bearings are considerably longer. For a 3/8" inner diameter, a ball bearing is only 5/16" wide. A 3/8" needle bearing without an inner race is .515" long, and with an inner race jumps to .569" long.---Not great when you are trying to fit them into 3/8" sideplates.

- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

I've also read that needle bearings must be run on hardened shafts. However, I've had 3/8" ID needle bearings running on my Hit n Miss engine for a number of years now and there is no sign of any wear. Of course, I only run my engine maybe an hour every couple of months. I think the "chewing" problem is more likely to occur if your shafts are under moderate to heavy loads or only after many hours of running them.

Either way, the note of caution is worth heeding for anybody contemplating the use of needle bearings. If someone chooses to take the risk, they can't say they weren't warned! :fan:

Chuck

Either way, the note of caution is worth heeding for anybody contemplating the use of needle bearings. If someone chooses to take the risk, they can't say they weren't warned! :fan:

Chuck

RonGinger

Well-Known Member

Cooling reservoirs are always somewhat of a pain, but I am thinking in terms of a plain o.d. cylinder, with a separate reservoir made from aluminum and mounted with o-ring seals.

I do not believe that a hopper full of water on the cylinder of an engine does anything to help cooling. There are 3 methods of heat transfer, conduction, convection and radiation.

A hopper of water does neither of these- I does not conduct heat any better than a metal, it does not convect heat away, and it does notradiate better than a black metal. If the water was so hot it was evaporating away it would carry off some heat, but no model engine Ive ever seen runs this hot.

Having a separate reservoir of water will also not carry away heat, unless the reservoir is finned, or has some air flow over it to carry the heat off by convection.

Of course, water run through a radiator with air flow over it can carry off heat. A friend of mine runs a Duclos odd and ends hit and miss engine at shows. He never puts water in it, and it runs all day without trouble.

jwcnc1911

-jwcnc191

- Joined

- Mar 19, 2013

- Messages

- 603

- Reaction score

- 86

I think a radiator brings a whole level of complication that would defeat the purpose of this engine. It's directed towards beginners after all.

IMHO bearings are better for this application any way. Needle bearings are for areas of higher radial load which just isn't seen in a model engine. You can get thin section bearings for about the same cost as a "regular" bearings.

Also, shouldn't this thread be titled "I am designing an I.C. engine---"

IMHO bearings are better for this application any way. Needle bearings are for areas of higher radial load which just isn't seen in a model engine. You can get thin section bearings for about the same cost as a "regular" bearings.

Also, shouldn't this thread be titled "I am designing an I.C. engine---"

- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

Brian,

3/8 ID bearings also come in a 5/8 OD flavor. Standard base part number is R1038 with a suffix for plain, shielded or with seals. Shielded work well for low friction as they do not add any friction to the bearing. The shield can be removed easily if necessary.

Although a little bit late for you for this build, AVID has ball bearings for radio control cars at a very reasonable price. Most are US$1 each. Have always shipped to me within a day with a $2 per order handling charge plus their cost for the shipping. They do ship to Canada.

http://www.avidrc.com/product/9/standard-bearings/

Gail in NM

3/8 ID bearings also come in a 5/8 OD flavor. Standard base part number is R1038 with a suffix for plain, shielded or with seals. Shielded work well for low friction as they do not add any friction to the bearing. The shield can be removed easily if necessary.

Although a little bit late for you for this build, AVID has ball bearings for radio control cars at a very reasonable price. Most are US$1 each. Have always shipped to me within a day with a $2 per order handling charge plus their cost for the shipping. They do ship to Canada.

http://www.avidrc.com/product/9/standard-bearings/

Gail in NM

Ron ginger--You are probably right. That being said, I remember as a boy seeing many of these engines in sawmill and agricultural use and they all had water reservoirs. They all were worked hard all day, and at noon lunch break they were always topped off with water to replace what had evaporated. Probably not needed for small model engines, as has been said, but I like them with a reservoir. I know that my Odds and Ends gets pretty hot, even with the water in the reservoir. I am going to design an alternate "bolt on" air cooled cylinder, so that people can build it either way.---Brian

Cogsy

Well-Known Member

I do not believe that a hopper full of water on the cylinder of an engine does anything to help cooling. There are 3 methods of heat transfer, conduction, convection and radiation.

A hopper of water does neither of these- I does not conduct heat any better than a metal, it does not convect heat away, and it does notradiate better than a black metal. If the water was so hot it was evaporating away it would carry off some heat, but no model engine Ive ever seen runs this hot.

Having a separate reservoir of water will also not carry away heat, unless the reservoir is finned, or has some air flow over it to carry the heat off by convection.

Of course, water run through a radiator with air flow over it can carry off heat. A friend of mine runs a Duclos odd and ends hit and miss engine at shows. He never puts water in it, and it runs all day without trouble.

Water has a much higher Specific Heat Capacity than most metals (over 4 times that of Aluminium for example), which means that it absorbs much more heat (energy) to raise it's temperature per degree than metals can (in general). So a lit match under a 1 gram piece of Aluminum will heat it to a much higher temperature than a lit match under 1 gram of water.

So the water acts as a big heat sponge and releases it into the surrounds through the normal means.

Surely to God if someone has enough mechanical smarts to build an engine, they will have enough brains to know how to figure out a belt driven fan!!! I will offer up the air cooled cylinder as an alternate design. I don't intend to build it. People who build the engine with the air cooled cylinder are on their own, fan wise.Cool Brian, are you going to put a belt driven fan on it for additional cooling?

Well Poop!!! I can't remember where I bought the small brass bevel gears that I used on my 3 ball governor. I have checked with the McMaster Carr catalogue and the W. M. Berg catalogue, and it doesn't seem to be either of them. I have lost the computer files from the time that I built that 3 ball governor with the gears on it to use on the Webster engine, in one of various computer crashes. I have a fairly good idea of what I want to do for a governor on this engine, but I first have to either buy the gears and then model them, or find somewhere with cad models of small bevel gears which I can download. I really hate to buy them first, because if they won't work for what I want to do, then I'm stuck with them. Its a lot safer to create an accurate model to see if it can be made to work with my assembly and THEN buy the gears.

jwcnc1911

-jwcnc191

- Joined

- Mar 19, 2013

- Messages

- 603

- Reaction score

- 86

Surely to God if someone has enough mechanical smarts to build an engine, they will have enough brains to know how to figure out a belt driven fan!!! I will offer up the air cooled cylinder as an alternate design. I don't intend to build it. People who build the engine with the air cooled cylinder are on their own, fan wise.

I literally laughed out loud at that. Was just wondering how far you were going to take it.

weez

Project Of The Month Winner

- Joined

- Dec 11, 2012

- Messages

- 193

- Reaction score

- 141

Try http://www.sdp-si.com/. They have downloadable models of the gears in their catalog. I have not bought anything from them but their prices seem reasonable.first have to either buy the gears and then model them, or find somewhere with cad models of small bevel gears which I can download.

Thanks Weez!!! Jwcnc1911--Yer going to make me crazy!!! ---And I did find a great site that lets you set up whatever your gear requirements are, and it will create a 3D model in whatever format you are using and let you download it.

http://www.rushgears.com/Tech_Tools/PartSearch8/partSearch.php?gearType=BEVEL

http://www.rushgears.com/Tech_Tools/PartSearch8/partSearch.php?gearType=BEVEL

Similar threads

- Replies

- 25

- Views

- 3K