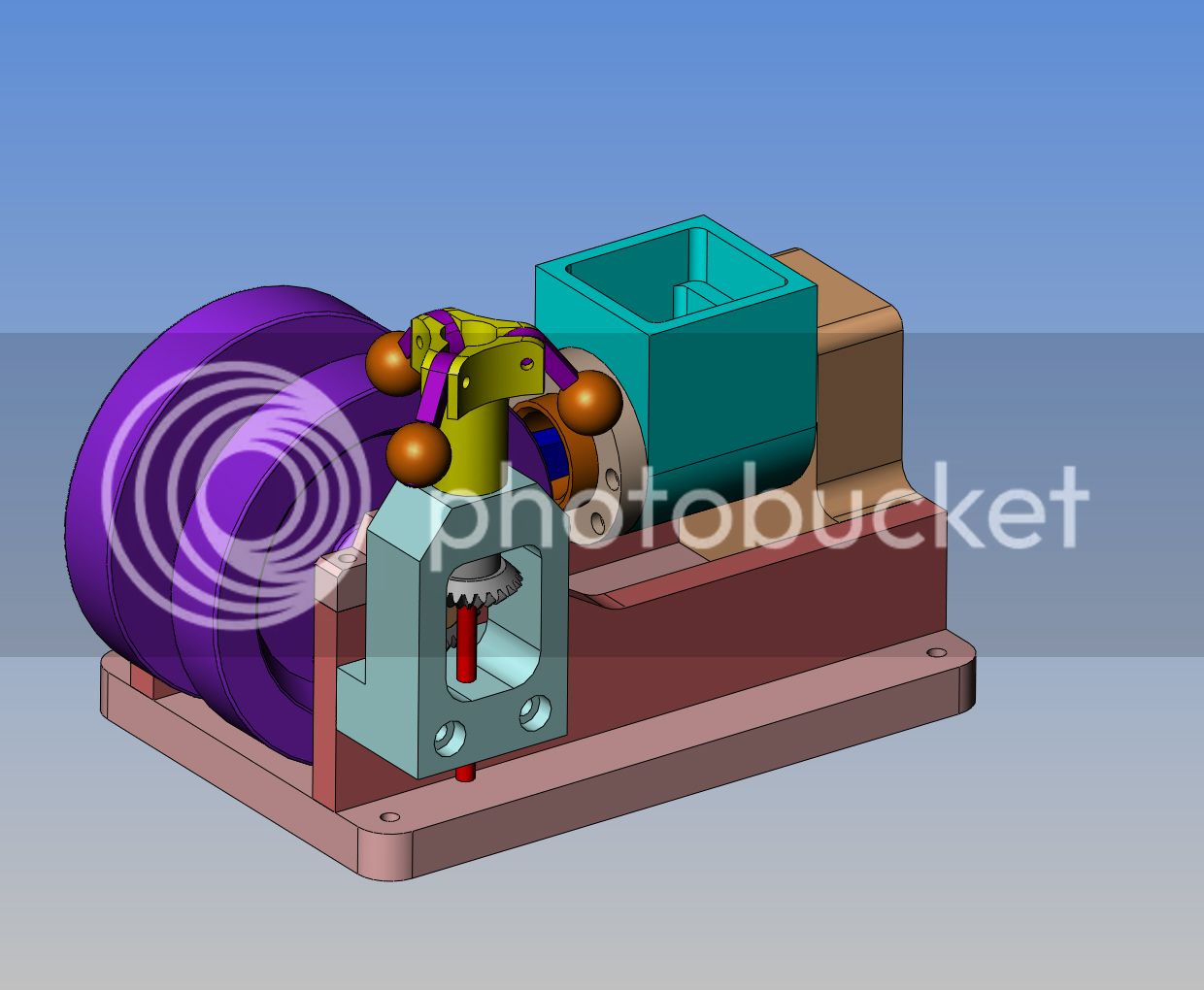

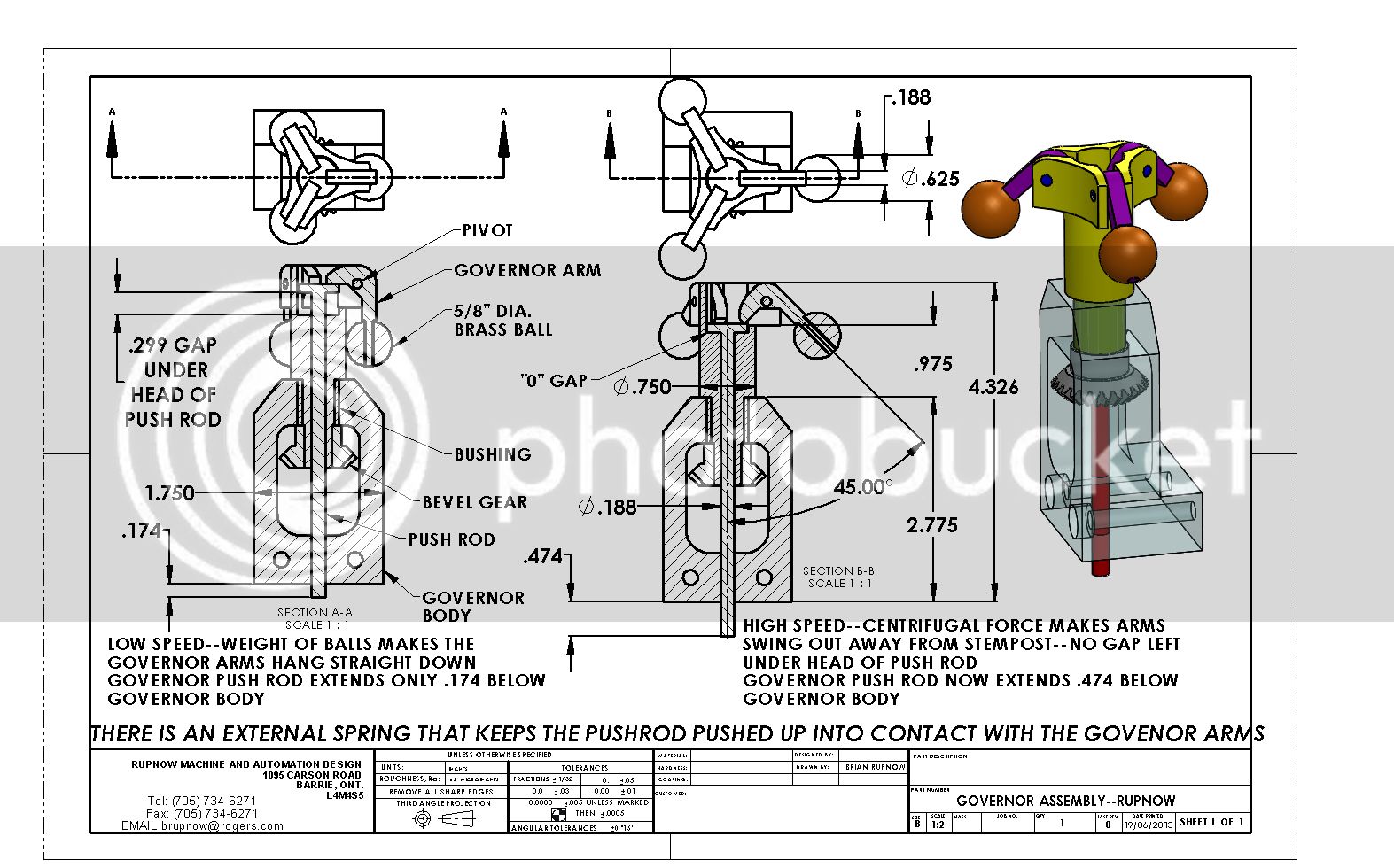

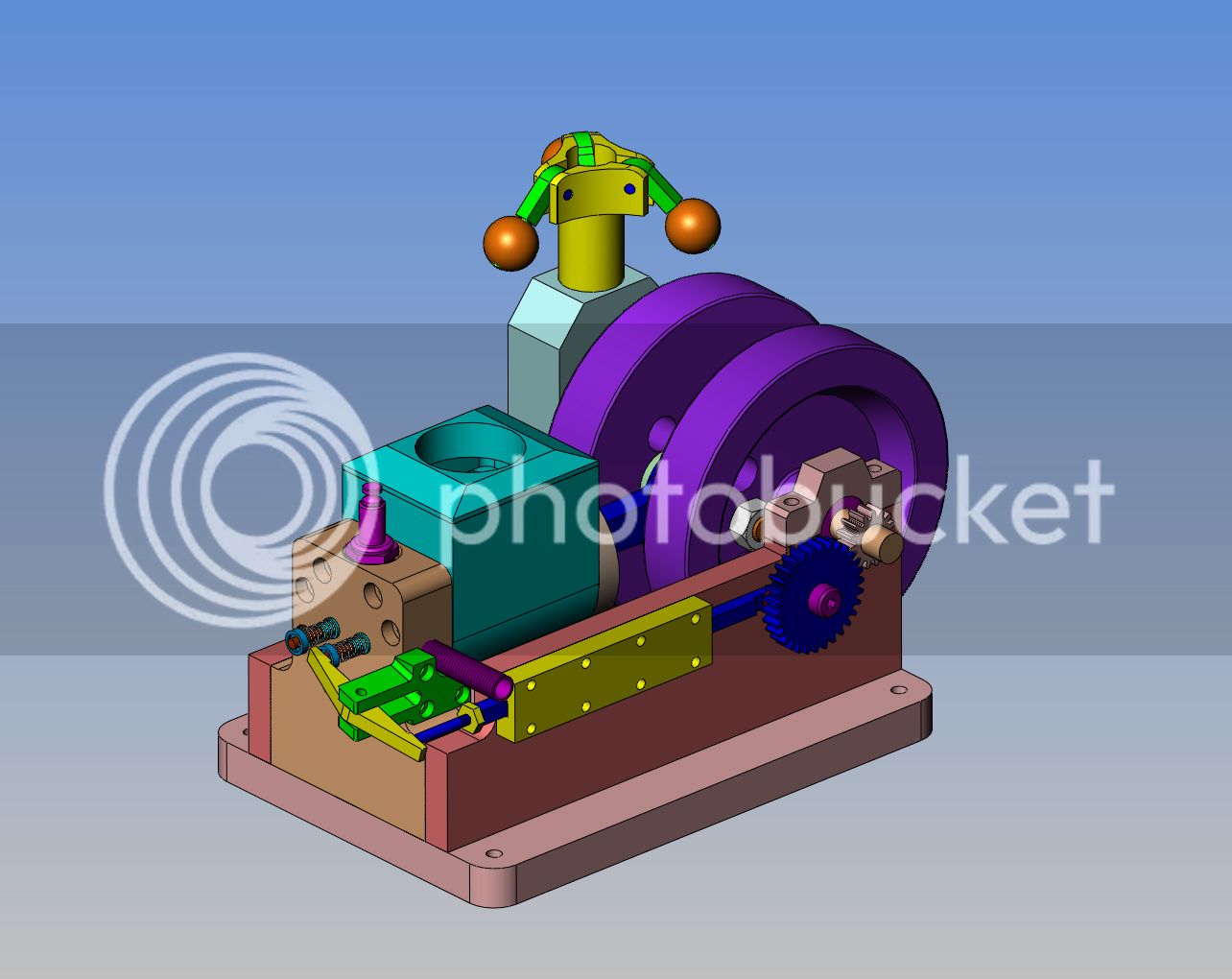

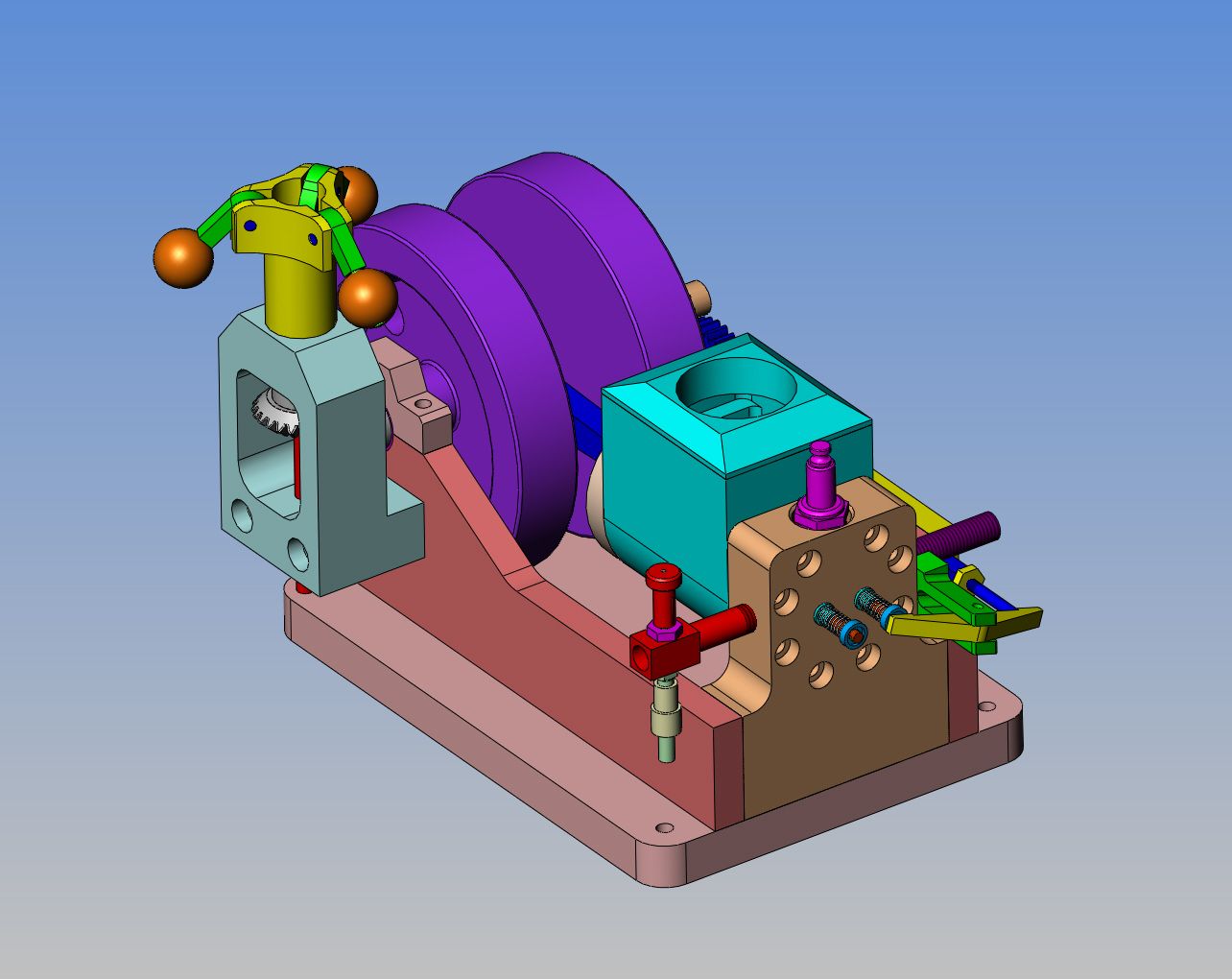

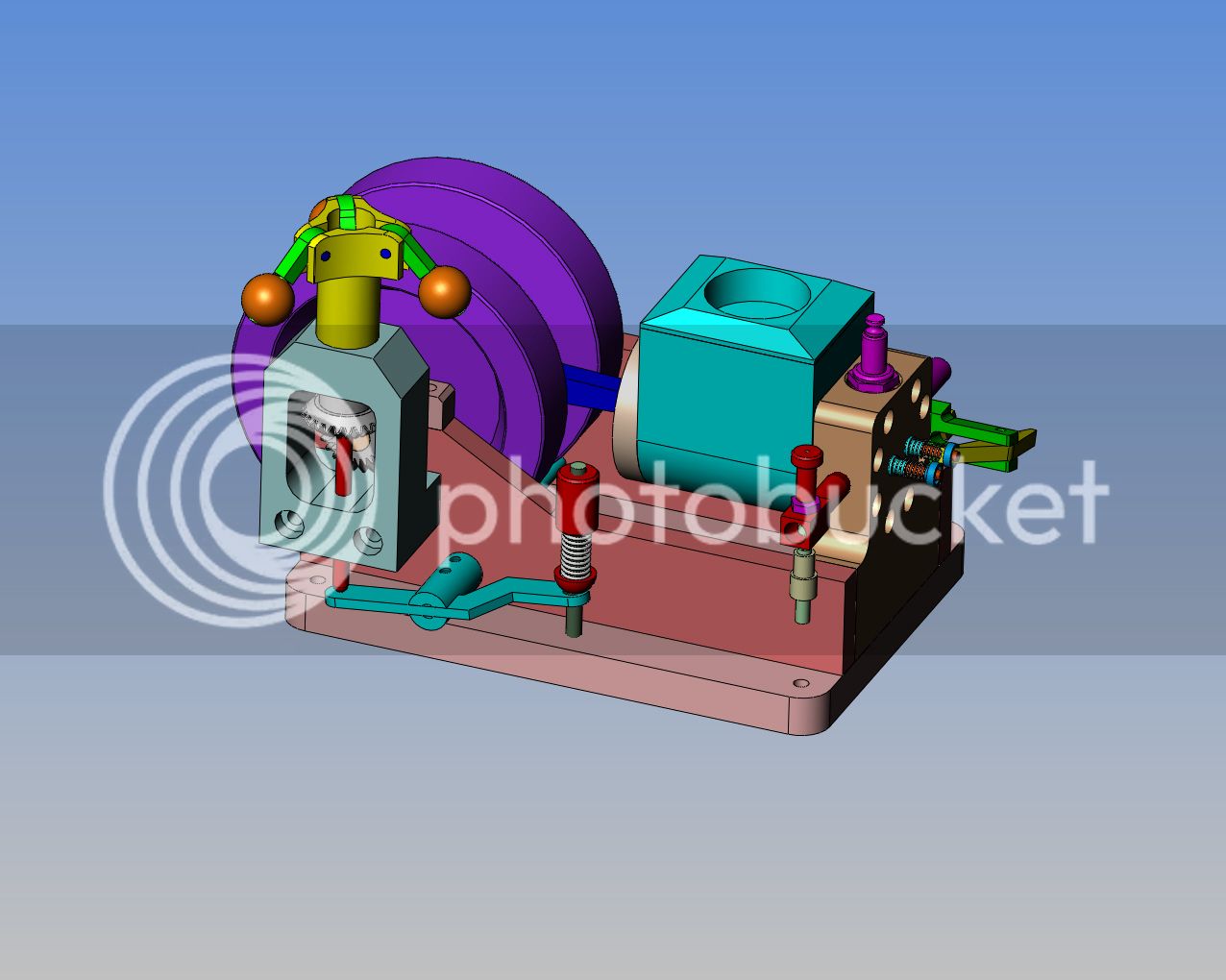

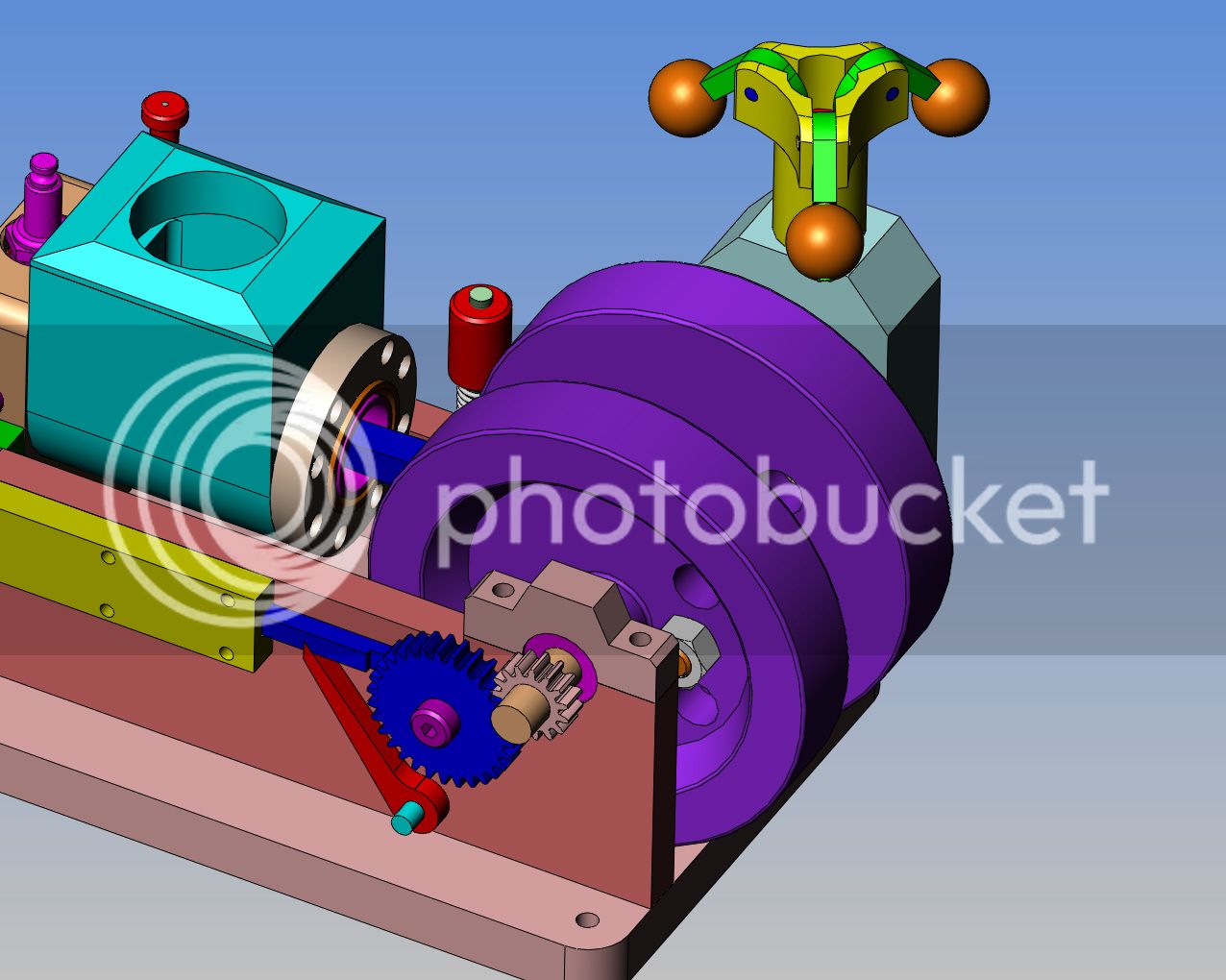

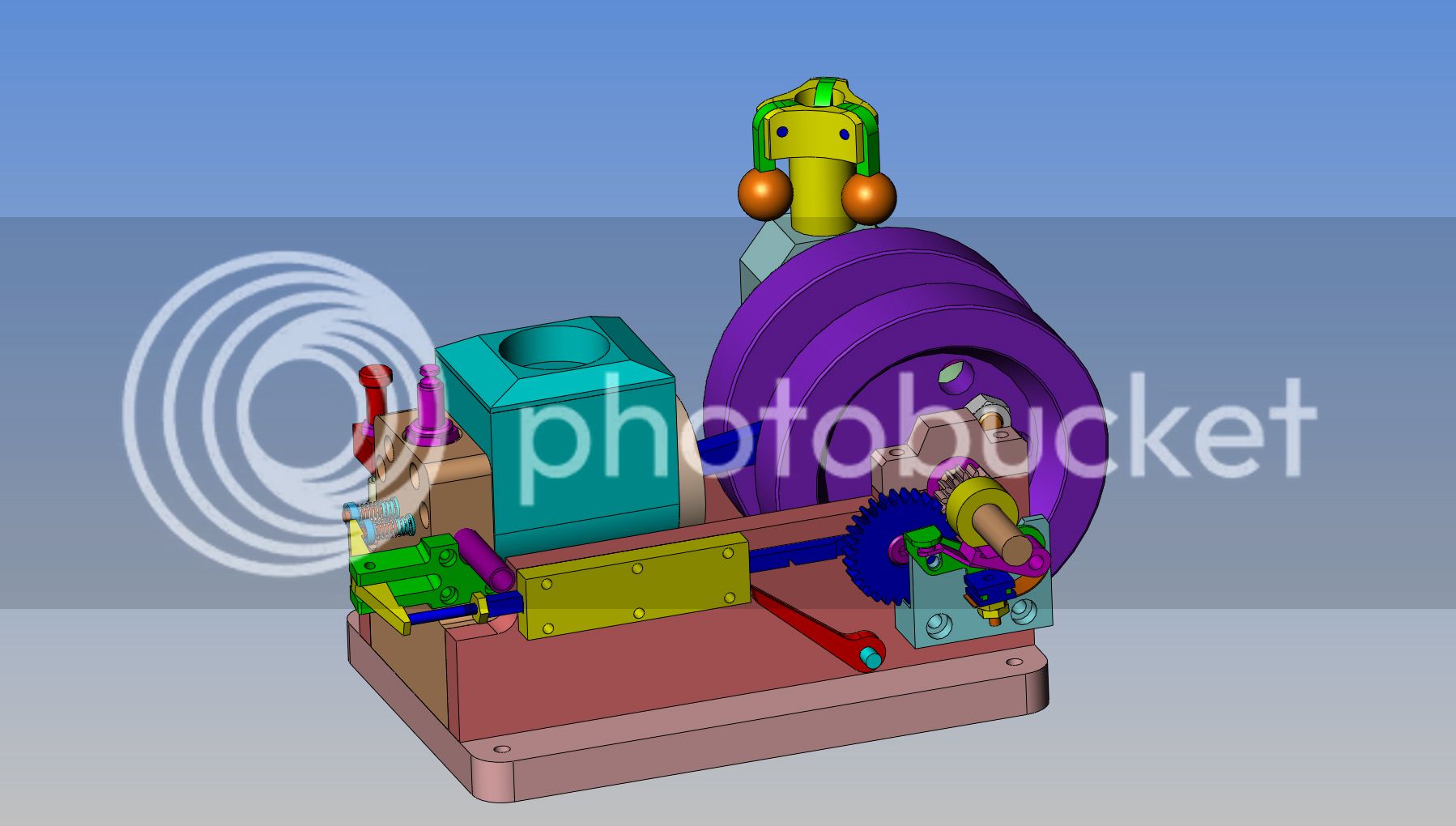

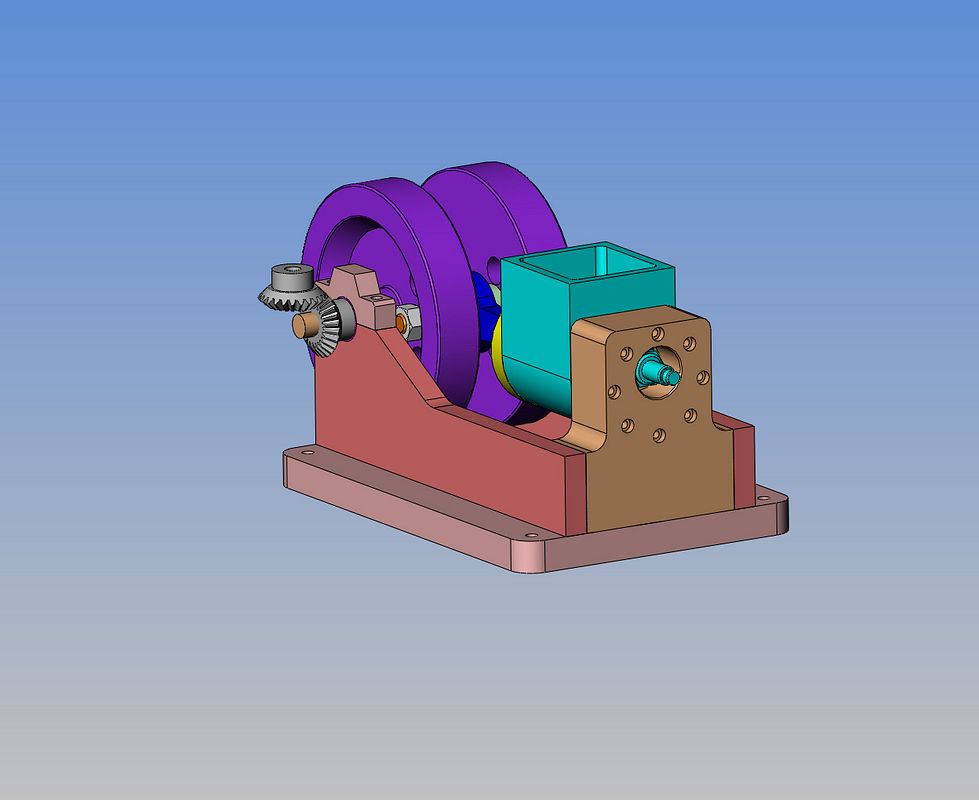

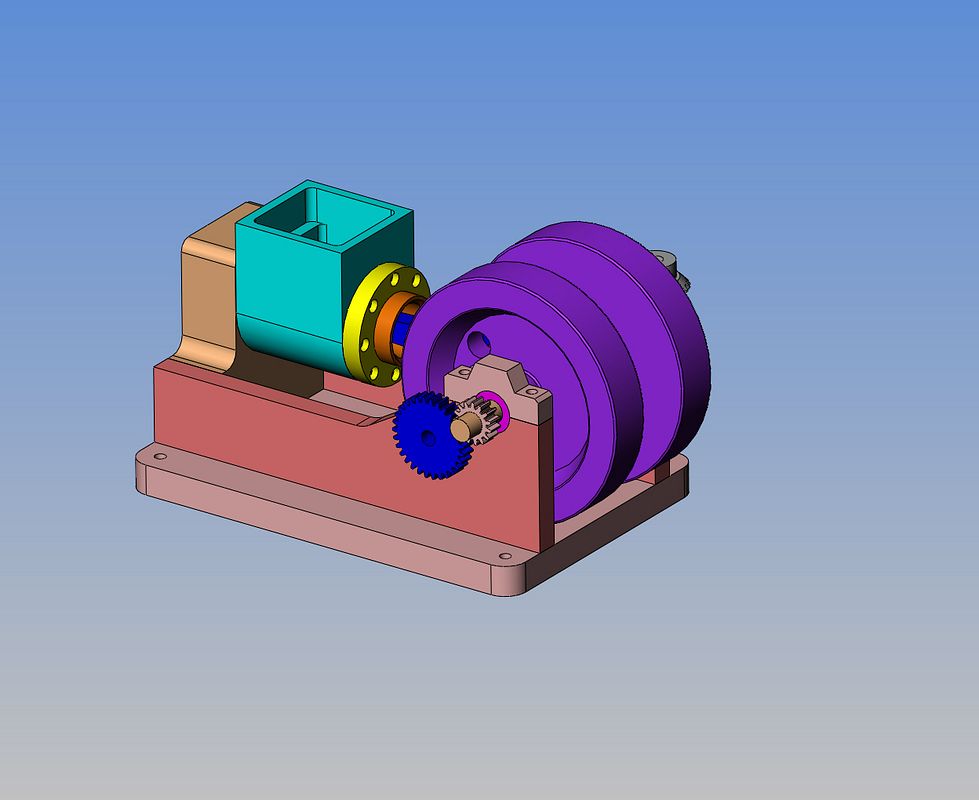

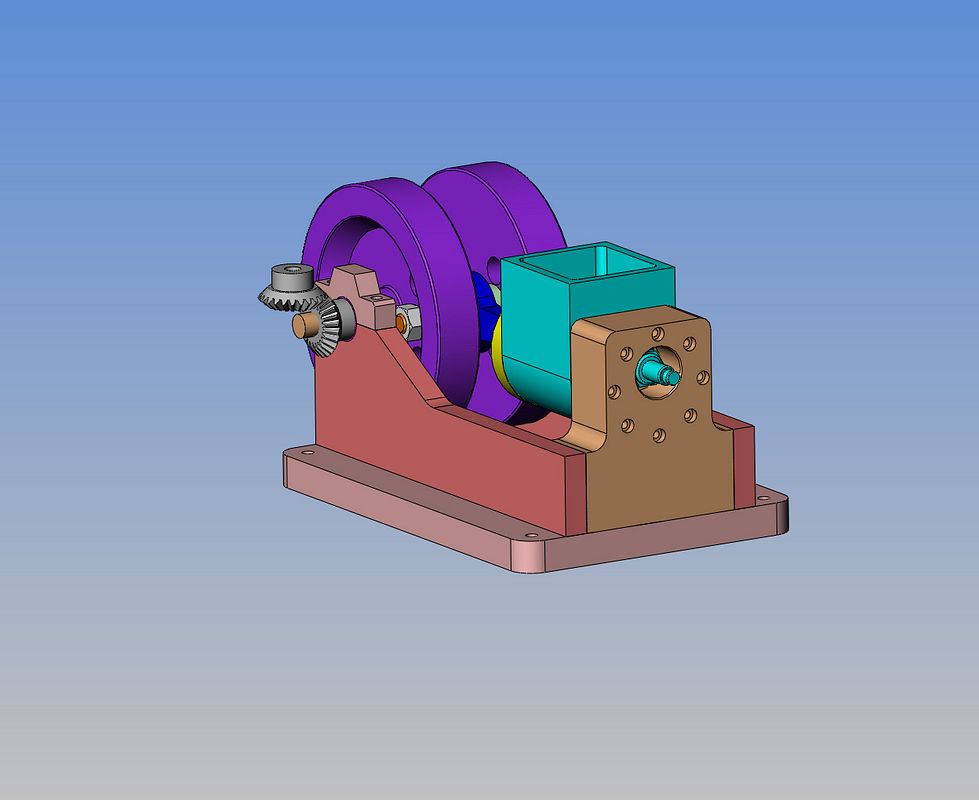

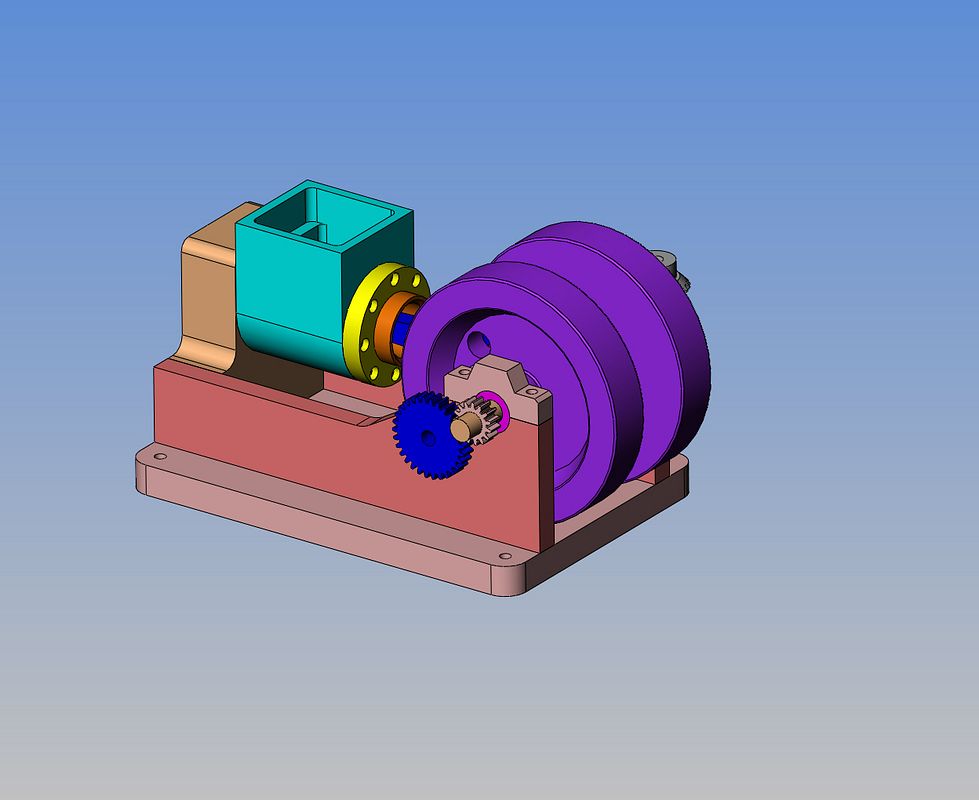

Okay---Now we're cooking!!! We got gears!!! The bevel gears are 24DP x24 teeth x 1" p.d. I have taken a good hard look at this thing, and at the size we are dealing with here, there is just no way to get the timing gears and the governor gears all on the same side of the engine. That's okay though. It makes the engine look more balanced with the governor on the opposite side. Of course this means I will have to run a pivot shaft across to the other side of the engine to latch the exhaust lifter rod, but I don't see that as a problem. The spur gears are 15 and 30 teeth 24DP x 1/4" wide, much the same as the Odds and Ends engine, just 1/16" wider.

Last edited: