After having built 4 i.c. engines and 12 different styles of air/steam engines, plus numerous "things" to run with these engines I may design an engine of my own. One of the most popular first time builders i.c. engines has been the Webster. It is a good running, 4 cycle, single cylinder air cooled engine, and has been built by many people around the world. The plans are free on the internet. The Kerzel hit and miss is another great i.c. engine, and is a single cylinder water cooled engine, with free plans on the internet. Both are simple engines to build from bar stock. I won't be designing a multi cylinder engine, nor a radial. My preference is leaning towards a single cylinder hit and miss engine, which uses a fly-ball governor rather than a flywheel mounted governor. If I do proceed with this, I will post free plans and "in process" pictures and technical write ups as the engine develops. My preference for the hit and miss water cooled engines stems from the fact that these engines can be run all day without overheating issues. Air cooled engines can only be ran for relatively short periods of time, (which is fine for presentation pieces) but they do have a tendency to overheat and seize if ran too long. I would like to hear input from other model engine builders to see which directions my design should take. I would like it to be an engine which is easy to build for first timers, uses only "bar stock" with no castings, and requires only a small lathe and mill and (possibly) a rotary table.----Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I may design an I.C. engine---

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Cogsy

Well-Known Member

Sounds like a brilliant idea Brian. I'd be very interested in building just such a beast from your plans.

motmaluk

Member

- Joined

- Apr 30, 2013

- Messages

- 23

- Reaction score

- 13

I too will be looking for a project engine in a few months,please persevere with your design,I will watch your progress with interest. The only point that I would like to make,and it's purely personal,I do prefer a pure IC engine,the hit and miss part I find a little fussy,let the thing run I say,but that's just my 2 cents worth.Good luck with your design!

Even a hit and miss engine will run like a standard 4 stroke engine if you don't build the governor part. All that is required in that case is a throttled style carburetor.

- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

Brian, if it's going to be a hit n miss, I don't think the water cooling is really necessary. My inverted hit n miss which has only a few, widely spaced fins, never gets above about 120 degrees F, even after 30 minutes or more. Being air cooled would certainly make it a lot simpler to build.

Also, running it with a vapor fuel tank would simplify things.

[ame]http://www.youtube.com/watch?v=cNm4idhYJZA[/ame]

This video was done before I cut the fins in the cylinder and painted it.

Chuck

Also, running it with a vapor fuel tank would simplify things.

[ame]http://www.youtube.com/watch?v=cNm4idhYJZA[/ame]

This video was done before I cut the fins in the cylinder and painted it.

Chuck

If you are going to do that, you might want to read Malcom Stride's book "Miniature Internal Combustion Engines." He kind of walks you through the design process. A lot of it is pretty self-evident, but some of it, I think, would be really helpful. Having built so many things, you might not need it, but if I were going to design one, I'd find it very helpful. I'd be glad to lend you my copy by mail, if you are interested.

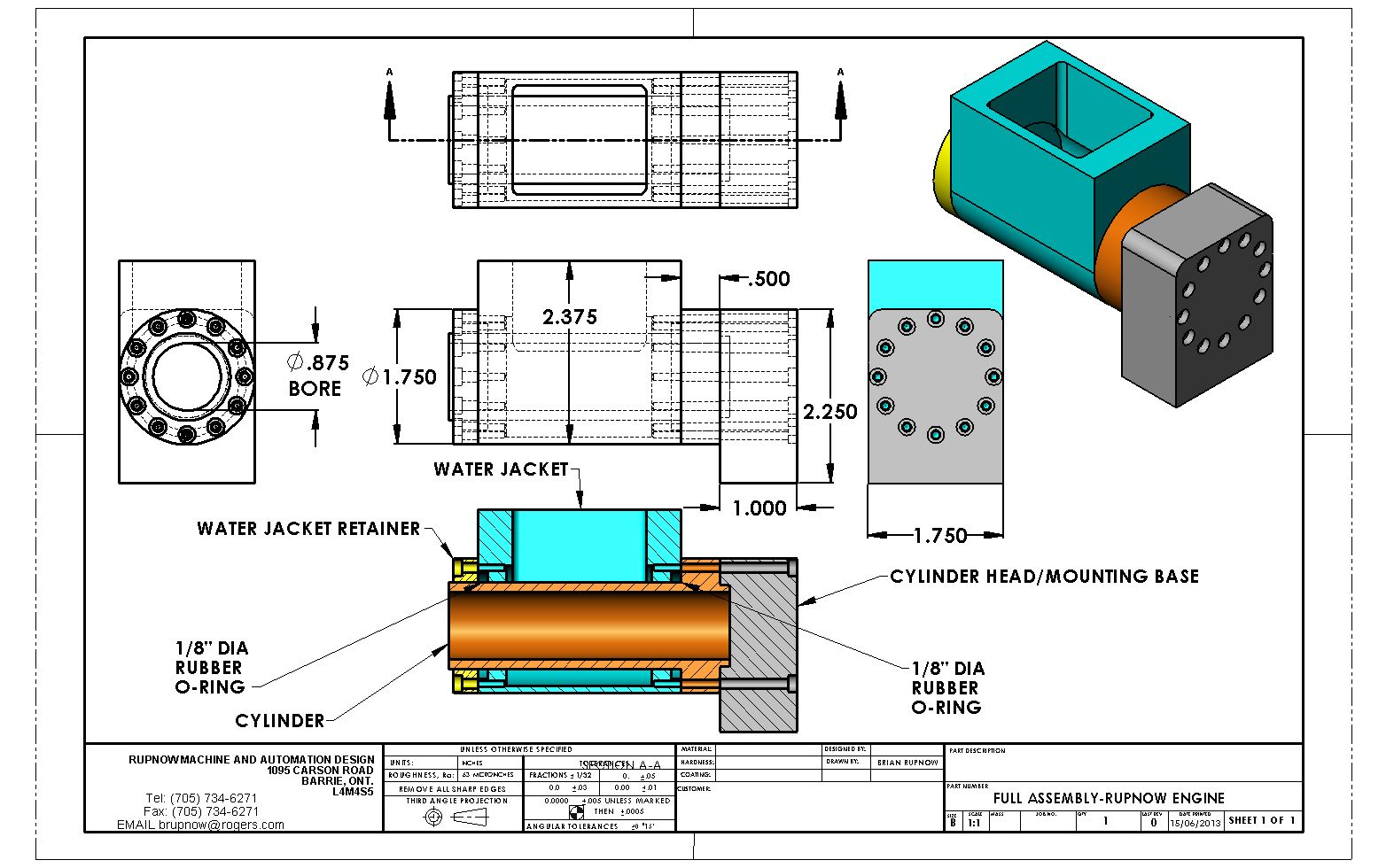

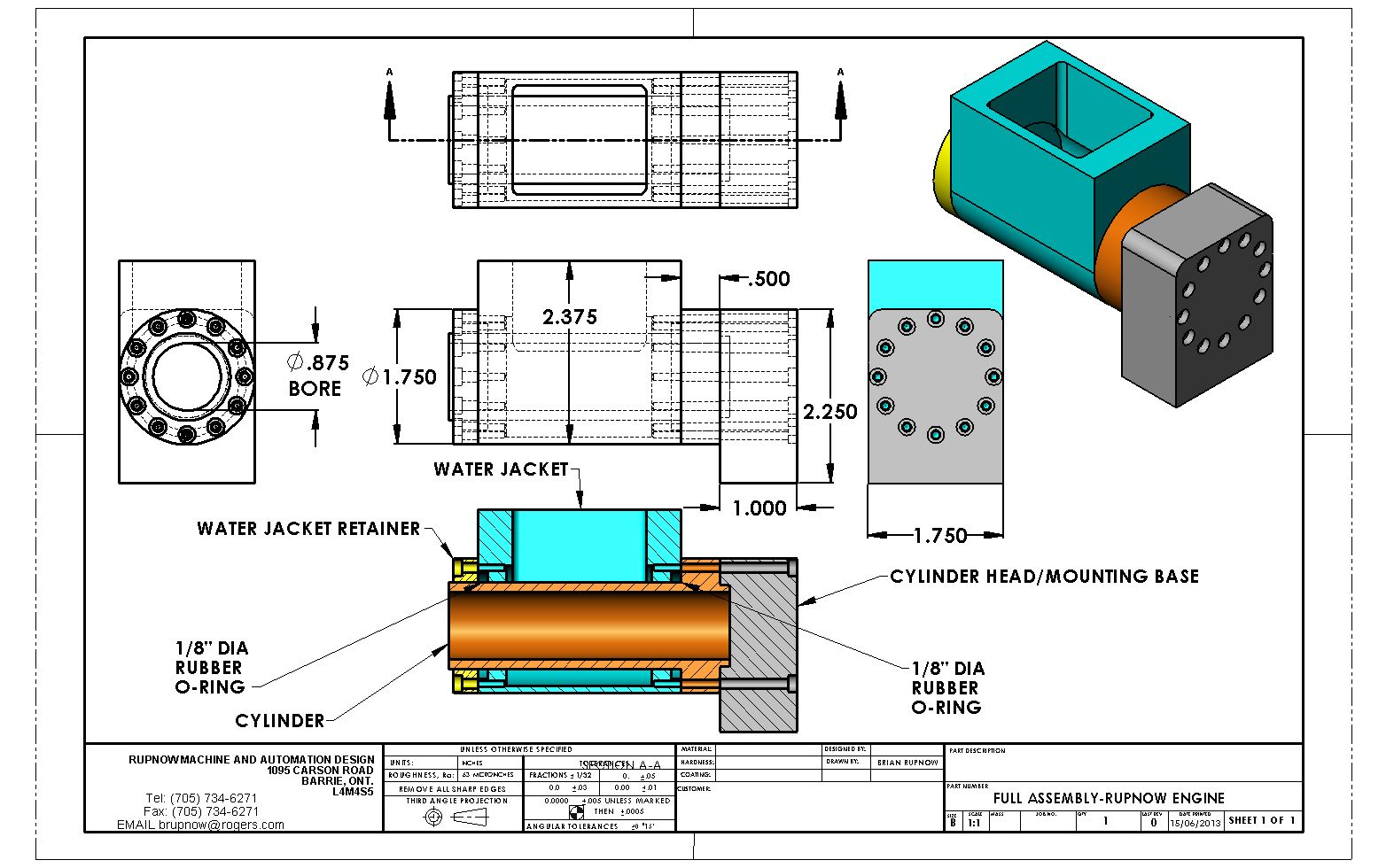

Thanks chuck.--Actually, I would like the engine I design to be somewhat generic.---That is to say, it could be built with the governor to give a hit and miss action, or without the governor but with a different carburetor to act as a simple 4 cycle engine. Cooling reservoirs are always somewhat of a pain, but I am thinking in terms of a plain o.d. cylinder, with a separate reservoir made from aluminum and mounted with o-ring seals.----Brian

Last edited:

The other reason for using a flyball governor, is that I would like to be able to adjust the spring tension on the governors while the engine is running, to dial in the "perfect" engine speed. On conventionally governed hit and miss engines, this can only be achieved by trying many different spring combinations until you find the engines "sweet spot". I would much prefer a system where that could be adjusted by means of a counter-spring mechanism while the engine was actually running.

Last edited:

I like the Idea of a simple bar stock engine whether it be of open or enclosed crankshaft design. Something along the lines of a single cylinder hoglet appeals to me. and being of a reasonable size so that the valves etc are not to fiddly.

- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

Brian, I'm sure what ever you come with will be a winner. It would be nice to have an alternative to the Webster, especially for first timers. You may already be familiar with this site, but if you go to the Gallery, there are lots of single cylinder engines that others have built. There is a vertical gallery and a horizontal gallery.

http://www.floridaame.org/

Chuck

http://www.floridaame.org/

Chuck

Cogsy

Well-Known Member

If I can make a suggestion it would be to use 2 smaller flywheels rather than 1 big one. I've just made 2 of them at 3.5 inches OD and that was stretching my nerve and abilities on my small lathe. I'd hesitate to attempt something with a 5 or 6 inch flywheel as a newbie.

I agree with Chuck - whatever you design will be brilliant.

I agree with Chuck - whatever you design will be brilliant.

roxwellmax

Active Member

- Joined

- Nov 9, 2011

- Messages

- 26

- Reaction score

- 14

Hello Brian,

I think your intension to design an engine along the lines mentioned is a great idea, I'll love to build it.

I have just completed a air cooled hit & miss engine, sort of my own design but based on the economy engine. I built this using material i had around the workshop so not the most beautiful but starts first time and runs perfectly using a flyball governor, trembler coil and vapor carburetor. I"m quite new to model engineering and completely self taught so much of the machining process is completed according to how I think it might be done which may not be the correct way but it's a great feeling to turn a pile of metal into something that resembles an engine and then fires up and runs, very satisfying.

Regards,

Max

I think your intension to design an engine along the lines mentioned is a great idea, I'll love to build it.

I have just completed a air cooled hit & miss engine, sort of my own design but based on the economy engine. I built this using material i had around the workshop so not the most beautiful but starts first time and runs perfectly using a flyball governor, trembler coil and vapor carburetor. I"m quite new to model engineering and completely self taught so much of the machining process is completed according to how I think it might be done which may not be the correct way but it's a great feeling to turn a pile of metal into something that resembles an engine and then fires up and runs, very satisfying.

Regards,

Max

Cogsy--I agree with you. Although my machines can handle fairly large stock (biggest being 6" o.d. as in the "Atkinson" flywheel, I think I will keep the flywheels to 4" maximum diameter for guys with smaller machines. By the same token, the bore will be kept to 7/8", and the stroke will be 1 1/2". This allows for a cylinder of 1 1/8" o.d. and a water jacket of 1 1/2" o.d. I may even go to 1 5/8" o.d. for the water jacket. I don't want to make the water jacket part of the supporting frame, because this engine will be designed in a somewhat "modular" style, allowing people to run either a water jacketed cylinder or a cylinder with cooling fins. I think the cylinder head will also be the main support for the cylinder, similar to the Webster. Will your machine handle that size of stock?---Brian

Last edited:

This is just some preliminary sketches, sorting out what I want to do in my own mind. The length of the cylinder is not to scale, as I haven't figured that out yet, but the rest of the drawing is to scale as far as regards the bore of the cylinder and a cross section thru the water jacket (which will be dependent on finished cylinder length.) The backing on the cylinder head is just a guess, and I know I haven't shown a sparkplug hole nor provision for valving, etc.--That will come as things develop.---Brian

Last edited:

Hi Brian,

Nice to see a new design coming along.

Have you considered eliminating the complication of actually surrounding the cylinder liner with coolant? The cylinder block and bore could be one solid piece with a fake hopper added for looks. My three hit & miss engines run almost continuously at the shows with no coolant at all. Granted, they idle and are not driving a load.

You could also design the cylinder block to look like the screen cooled engines which have no hopper. Again, no need to cool the liner.

Good luck with your project.

Regards,

Chuck Kuhn

Nice to see a new design coming along.

Have you considered eliminating the complication of actually surrounding the cylinder liner with coolant? The cylinder block and bore could be one solid piece with a fake hopper added for looks. My three hit & miss engines run almost continuously at the shows with no coolant at all. Granted, they idle and are not driving a load.

You could also design the cylinder block to look like the screen cooled engines which have no hopper. Again, no need to cool the liner.

Good luck with your project.

Regards,

Chuck Kuhn

Hi Brian,

Nice to see a new design coming along.

Have you considered eliminating the complication of actually surrounding the cylinder liner with coolant? The cylinder block and bore could be one solid piece with a fake hopper added for looks. My three hit & miss engines run almost continuously at the shows with no coolant at all. Granted, they idle and are not driving a load.

You could also design the cylinder block to look like the screen cooled engines which have no hopper. Again, no need to cool the liner.

Good luck with your project.

Regards,

Chuck Kuhn

In this case, the liner is the cylinder. In keeping with the "modular" concept, one could use a finned cylinder without any water reservoir at all.----Brian

Right, I see that the liner is the cylinder, but what I was getting at was eliminating the need for the O-ring seals. The cylinder and hopper could all be one piece of metal with no water passage surrounding the cylinder. Just a thought. Maybe I didn't say it clearly.

Regards,

Chuck

Regards,

Chuck

Similar threads

- Replies

- 25

- Views

- 3K