Metal Mickey

Well-Known Member

- Joined

- Jul 5, 2008

- Messages

- 612

- Reaction score

- 6

Hello all. I have some very expensive special steel for making a crankshaft for my Seal 15cc Westbury engine build. The size I have means that if I can slice it I can have enough left over for another and it seems a shame to just mill it away.

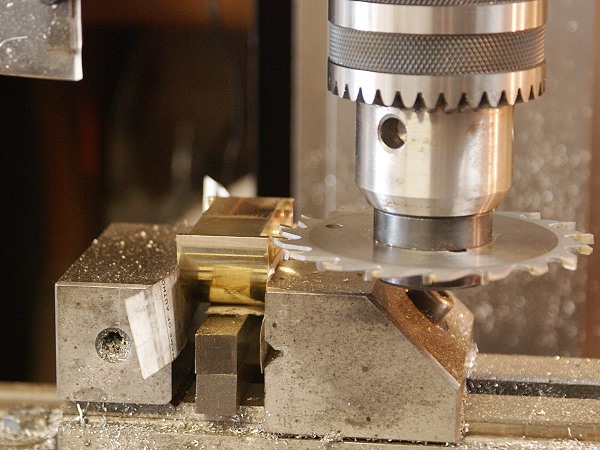

It is two long to use my bandsaw and if I use a slittling saw how would I hold it in a fixture to cut all the way through? Thats if I can get a saw with enough cutting depth and it would take some time as well. Any ideas?

MM

It is two long to use my bandsaw and if I use a slittling saw how would I hold it in a fixture to cut all the way through? Thats if I can get a saw with enough cutting depth and it would take some time as well. Any ideas?

MM