- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

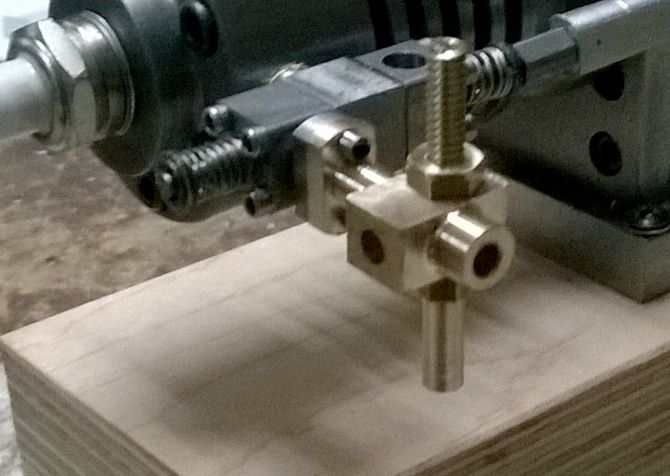

Chuck--I just checked in my machinists handbook, and the maximum o.d. of a #1-72 fastener is .073". that is REALLY small. Hard for me to imagine putting a thread that small in to mild steel. Amazing work!!---Brian

Thanks, Brian. I actually have better luck with the smaller threads. I've gone down to 0-80 in aluminum. I think 4-40 is the worst. I've broken more 4-40 taps than any other.