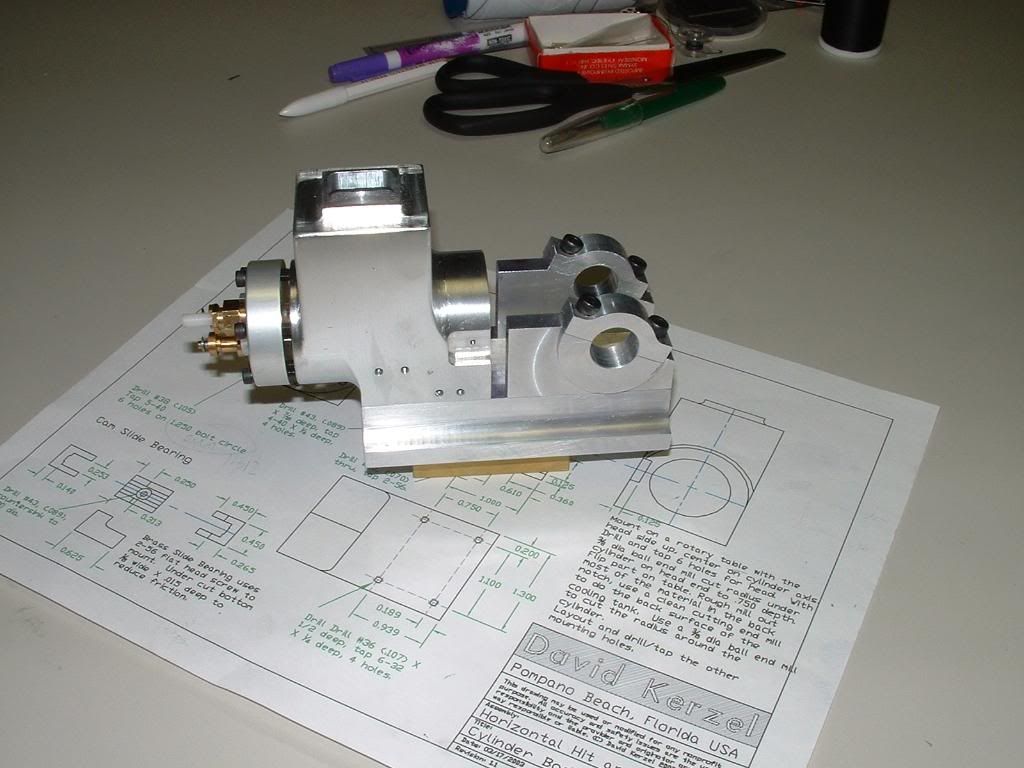

Hi guys, here are a few shots of my Horizontal Hit and Miss that has been cooking for the past ... 3 years at least (so long that I lost when it started)

It has been put aside many time to move other projects forward.

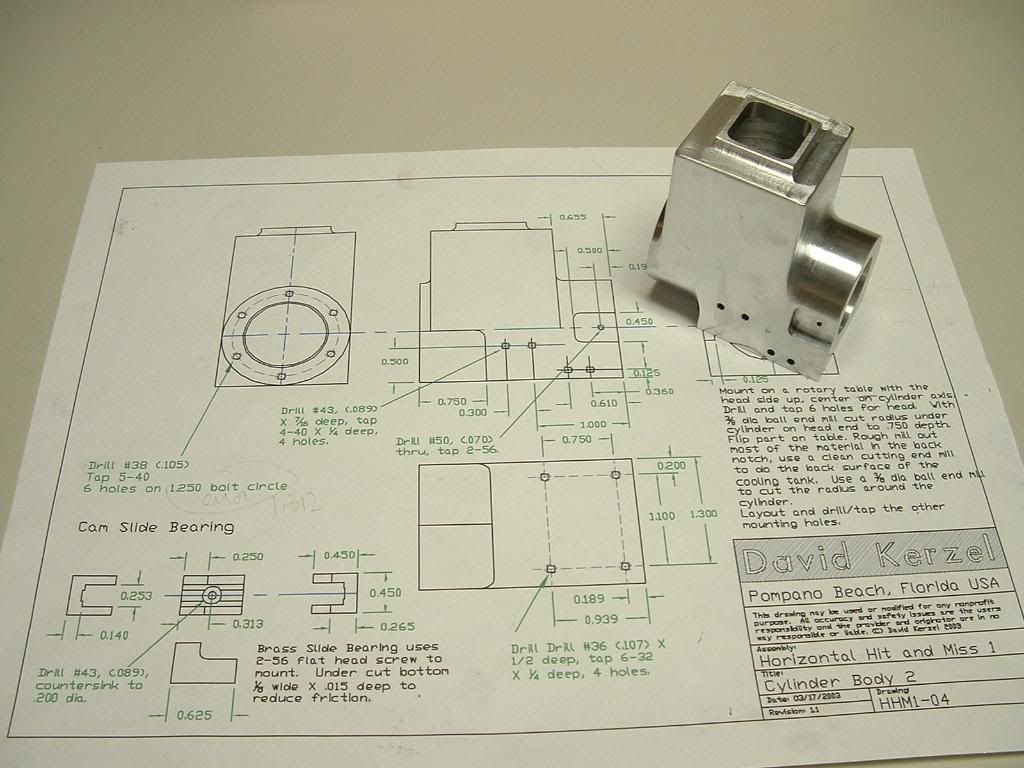

It is a design from David Kerzel , FL which was available for download at that time but seems no longer to be. Many thanks again to David for sharing his top quallity drawings with the community on the other forum ...

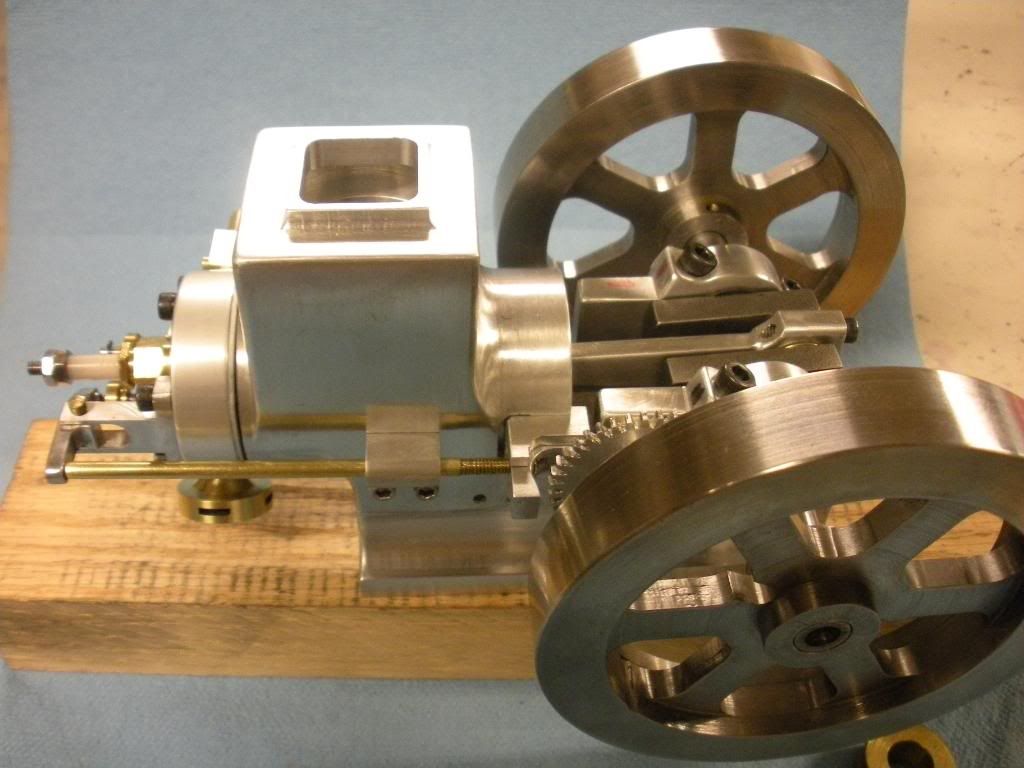

The engine is .75" bore x 0.8" stroke, water cooled jacket around cast iron sleeve / piston. All parts made from bar stock.

Here we go.

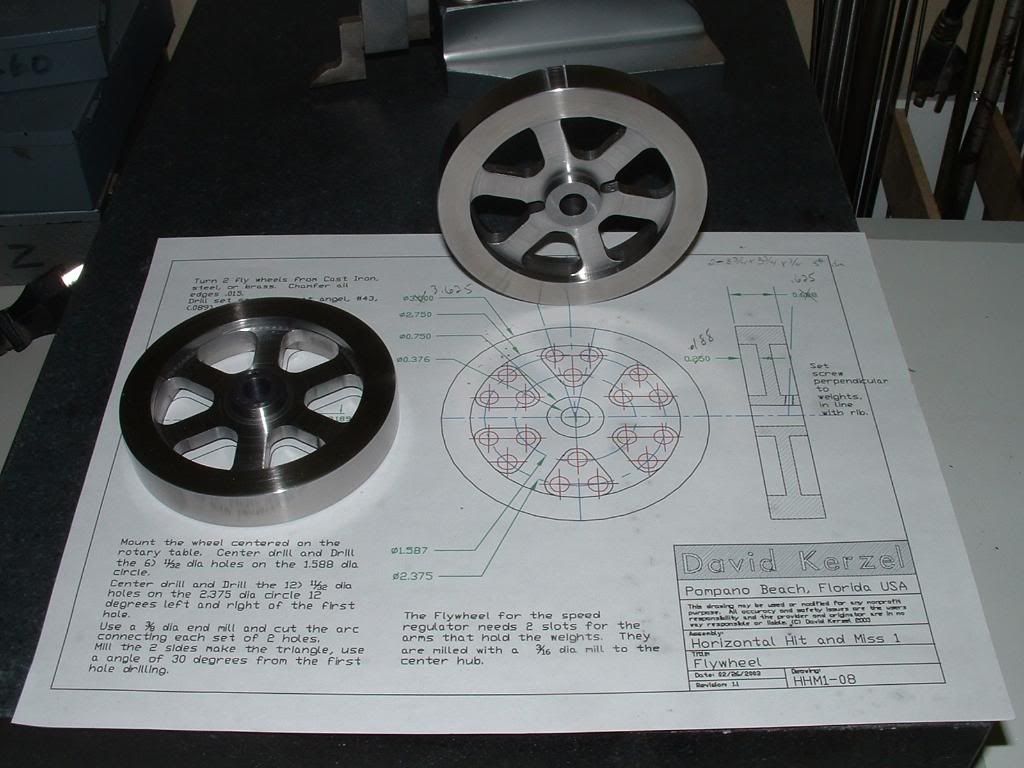

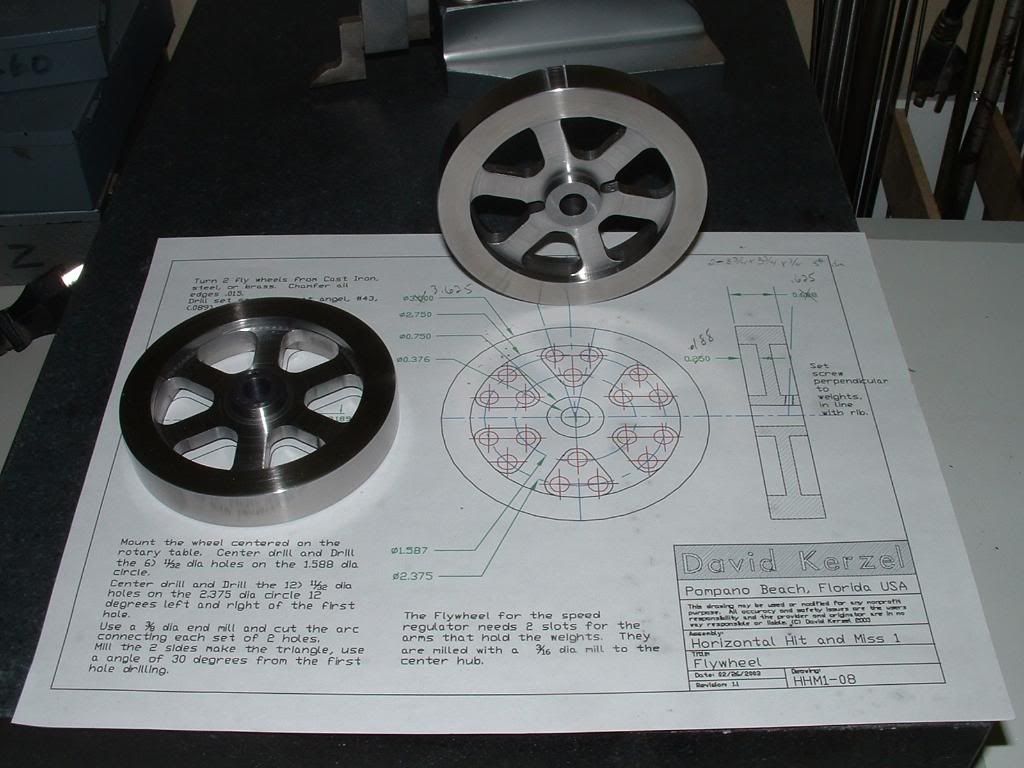

First thing done were the flywheels which took tremedous amount of time as they were first cut from a plate then turned. Cutting operation itself took the most time on my taiwanese band saw.

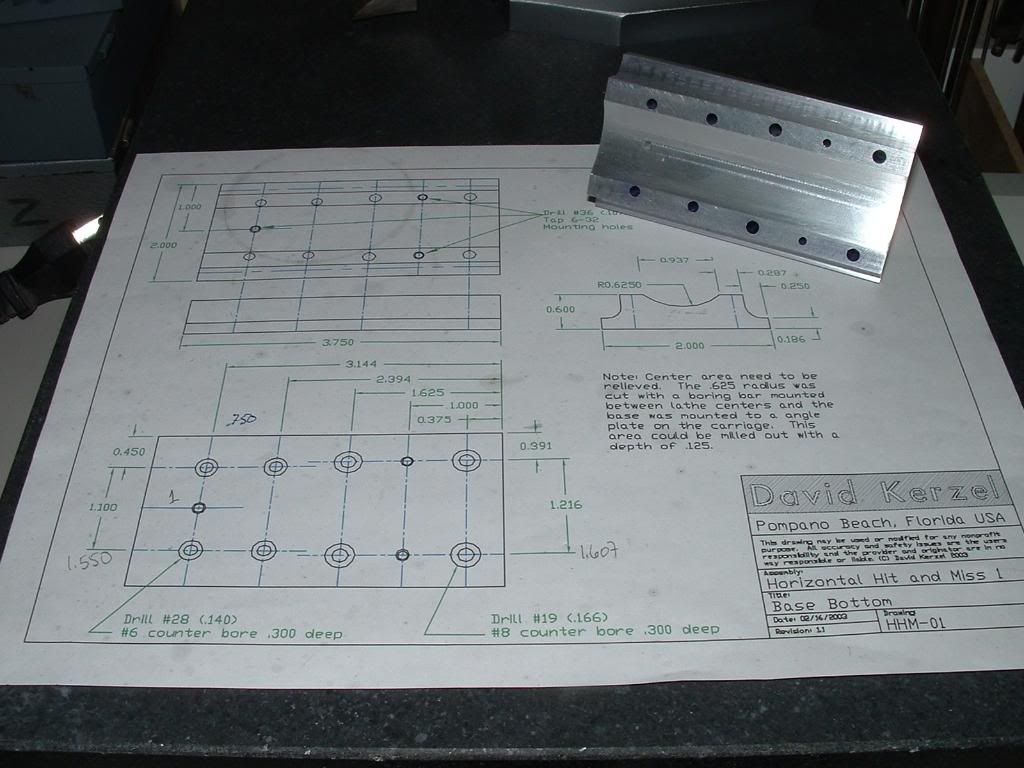

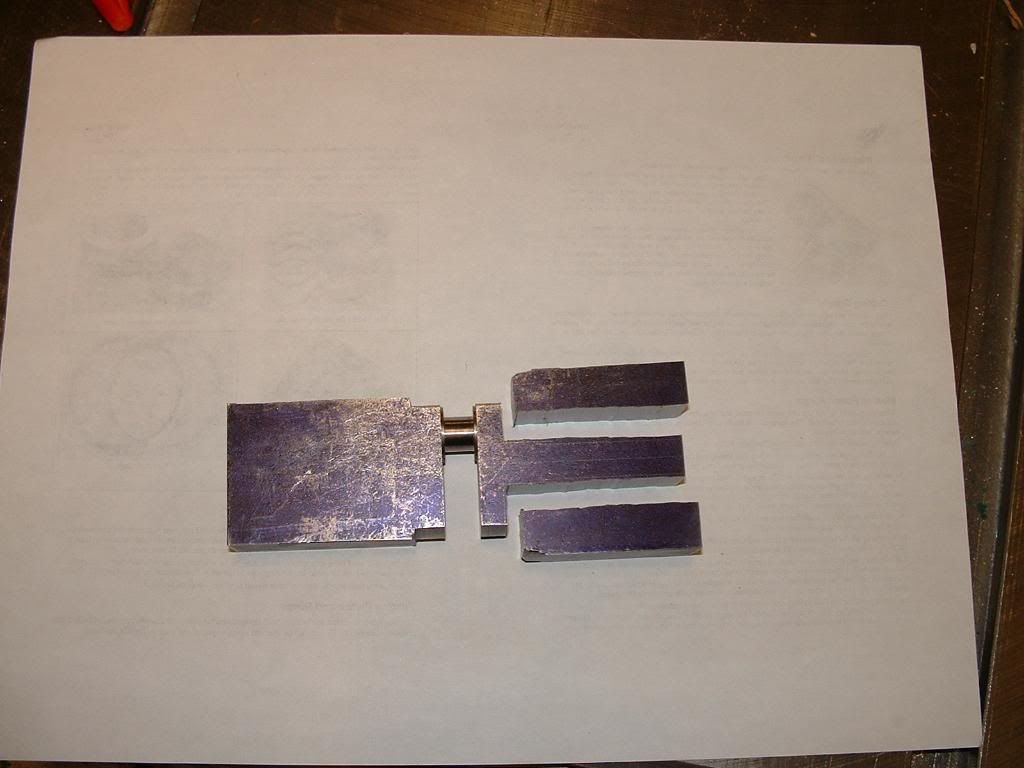

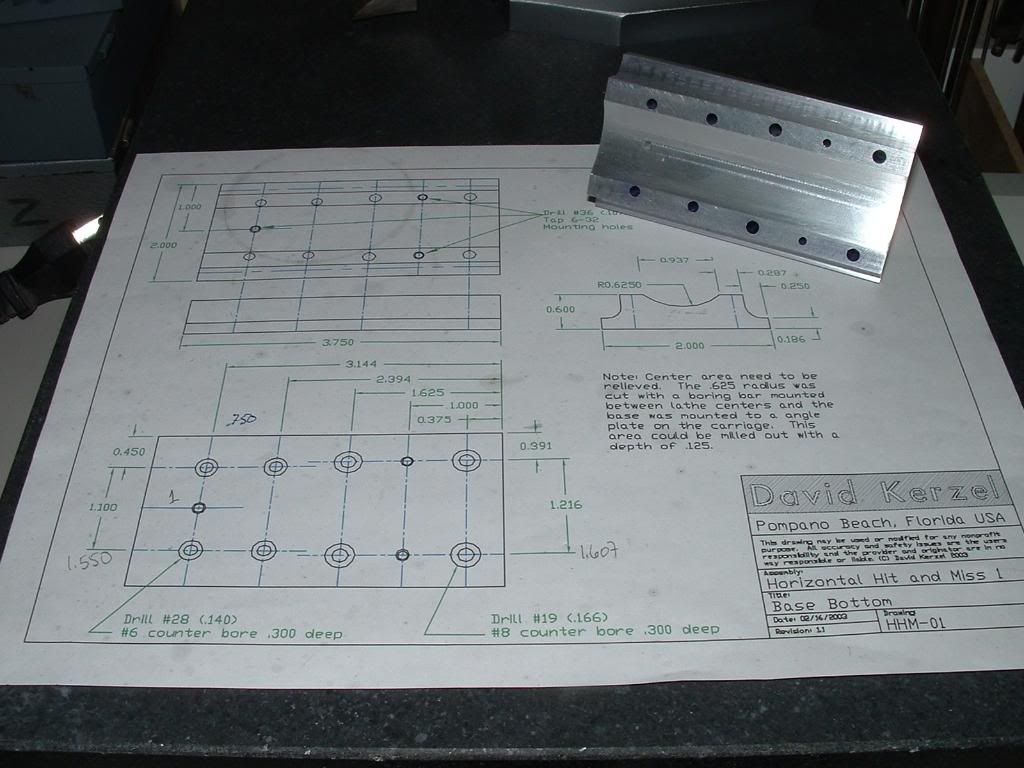

Next was a fairly simple part, the base unit.

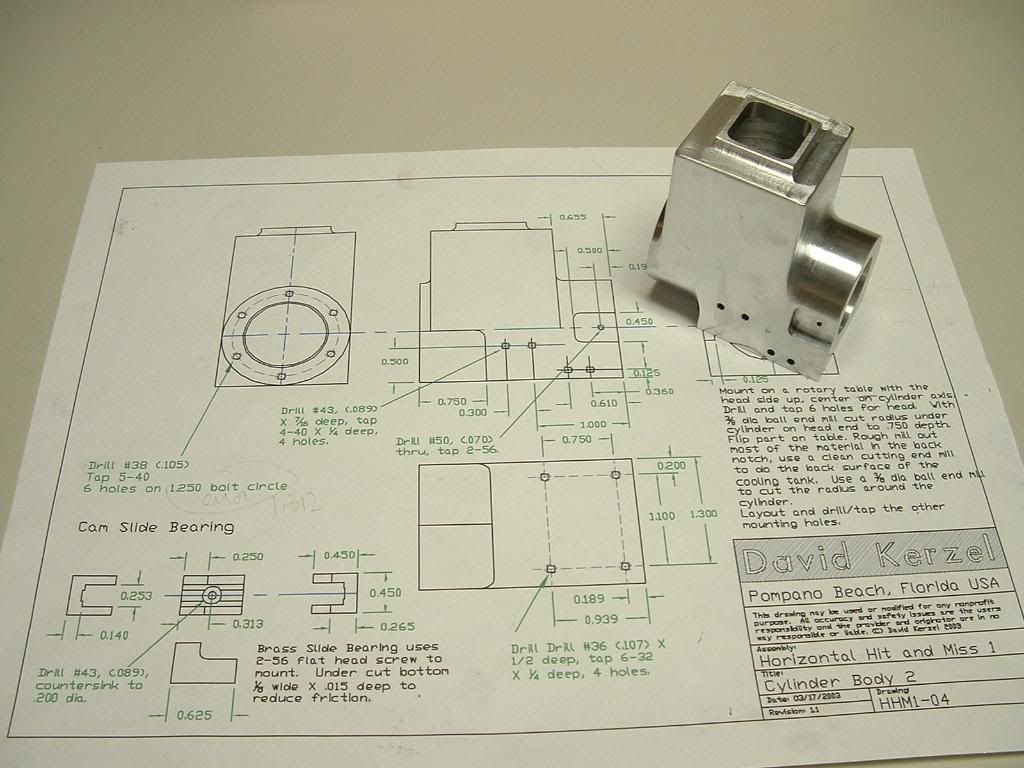

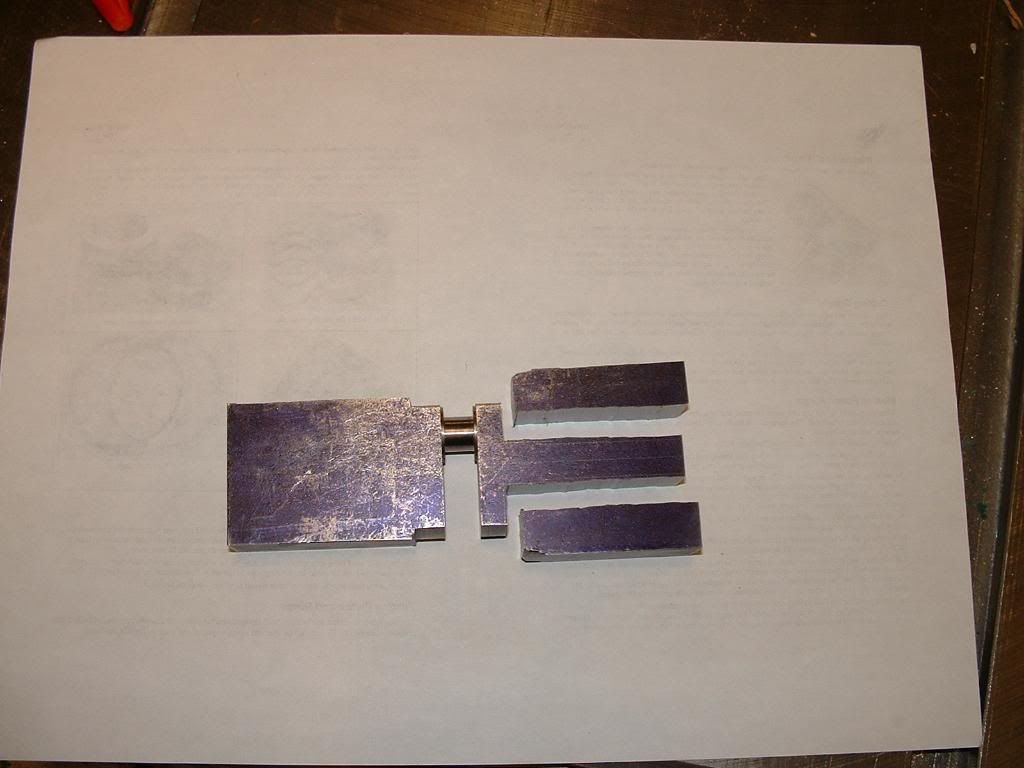

Then some challenge and lots of filing practice ...

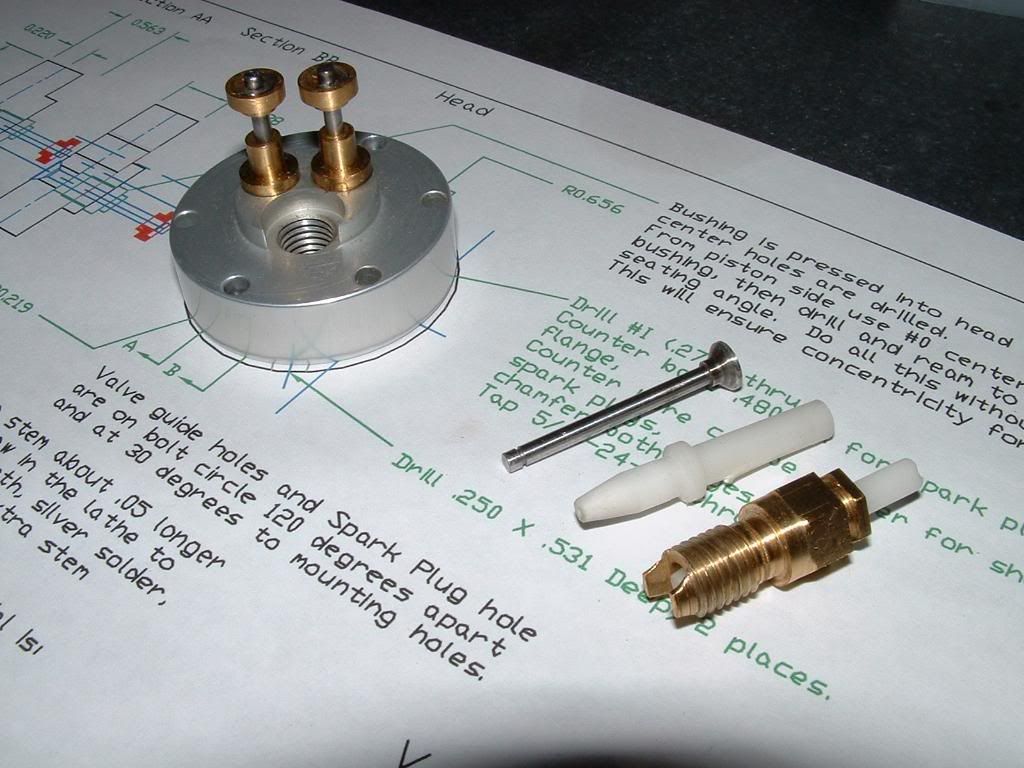

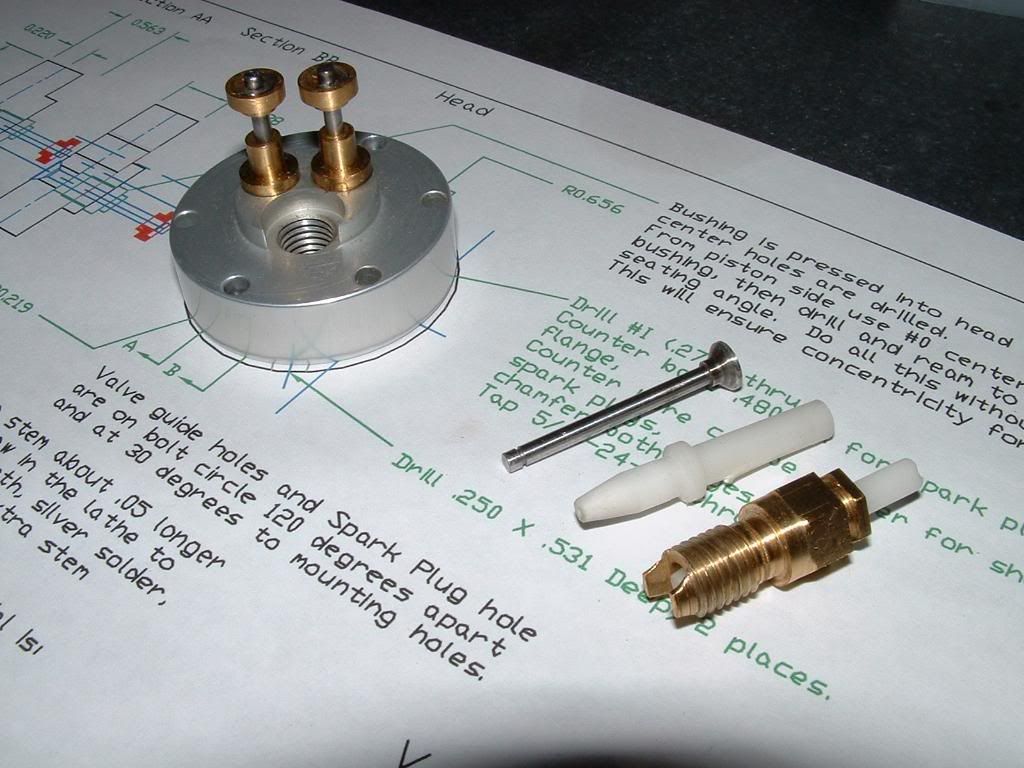

Now time for some very small parts, the head the valves , assembled spark plug.

The spark plug insulator was made from Corian, a real best to work with specially when drilling 1/32" x 1-1/4" hole :bow:

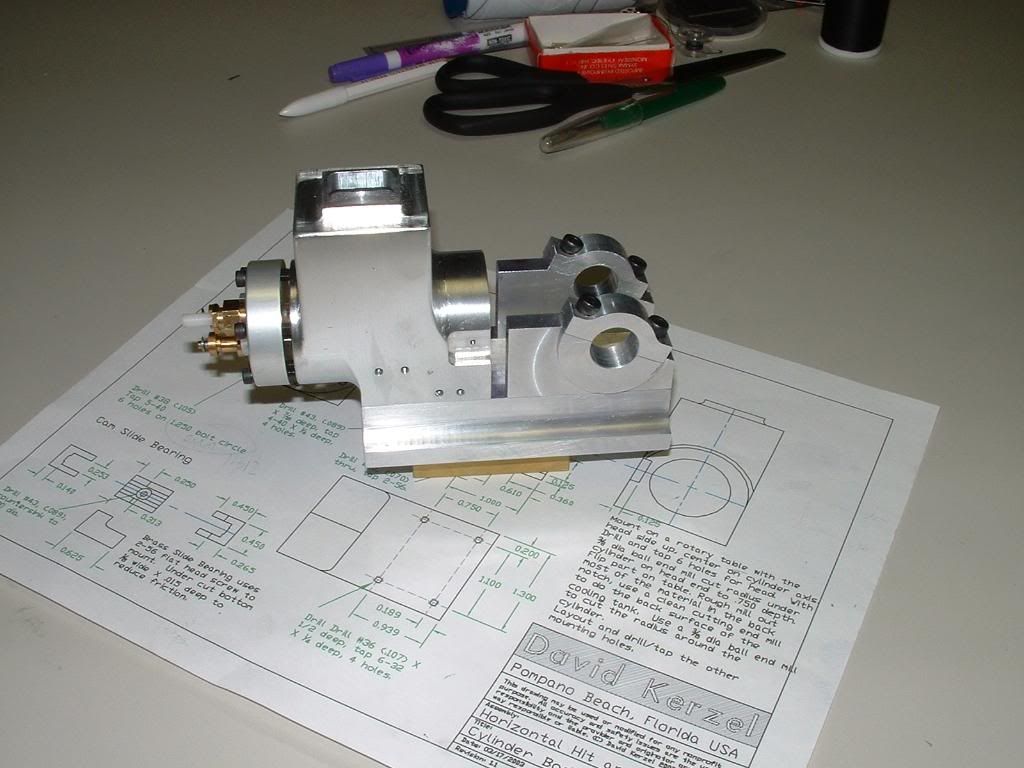

A few more parts and a first pre-assembly

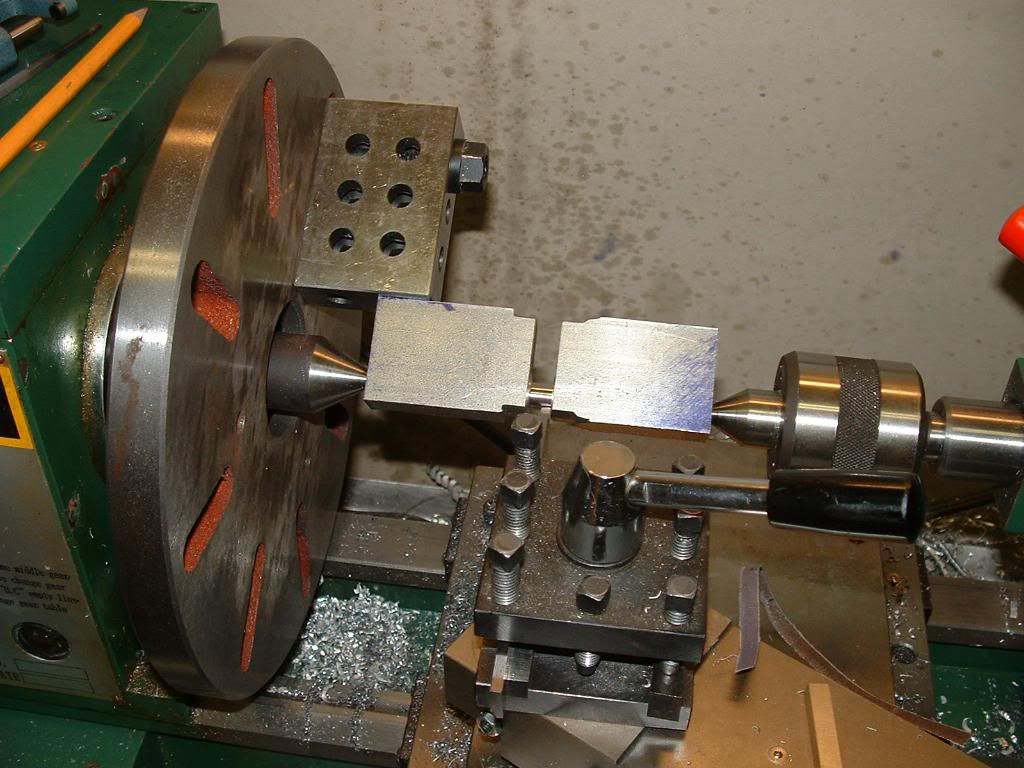

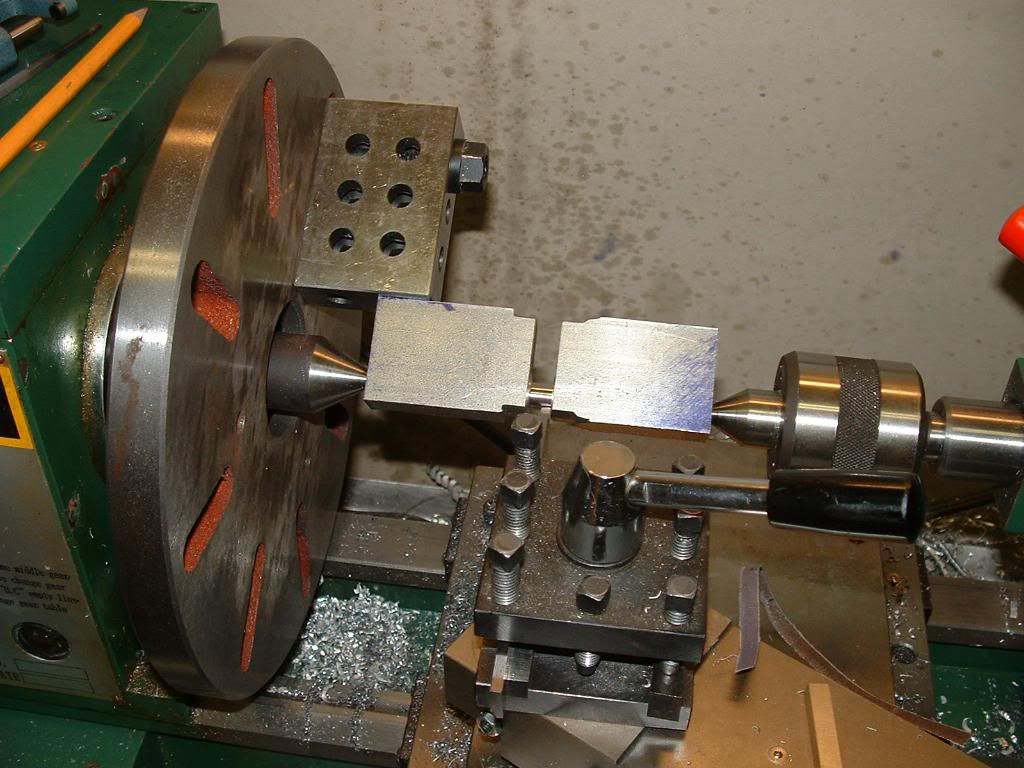

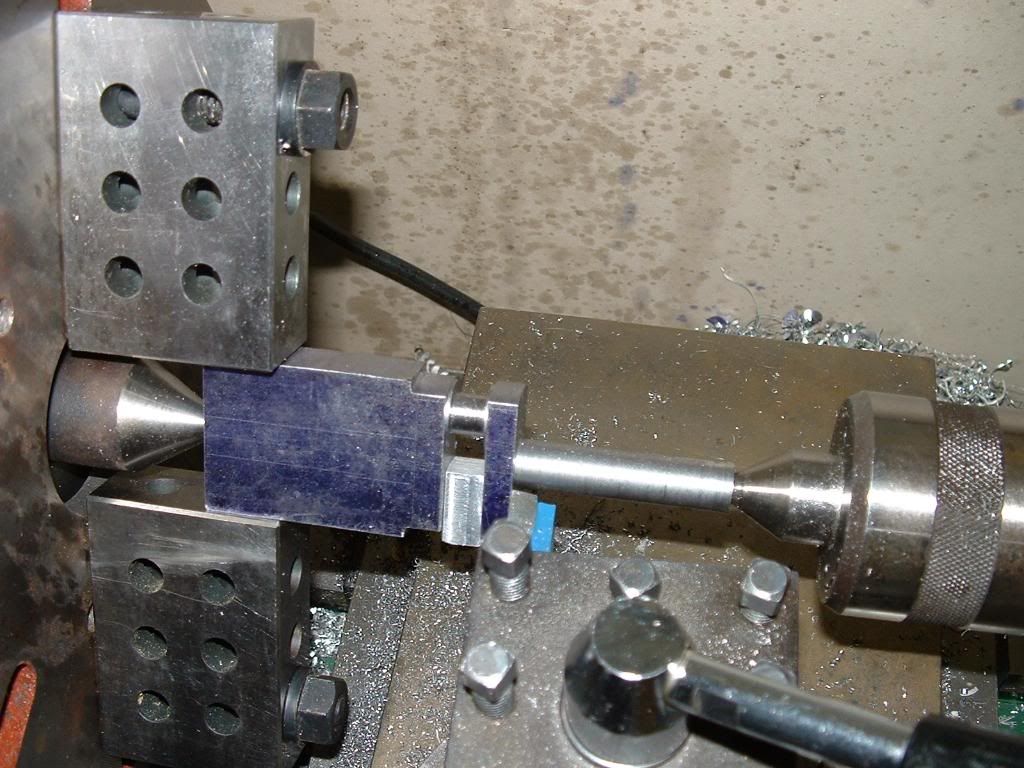

Then came my first experiment to make a long crankshaft from a solid bar

Please no comments on the Dog used ! Had to use what I had on hand.

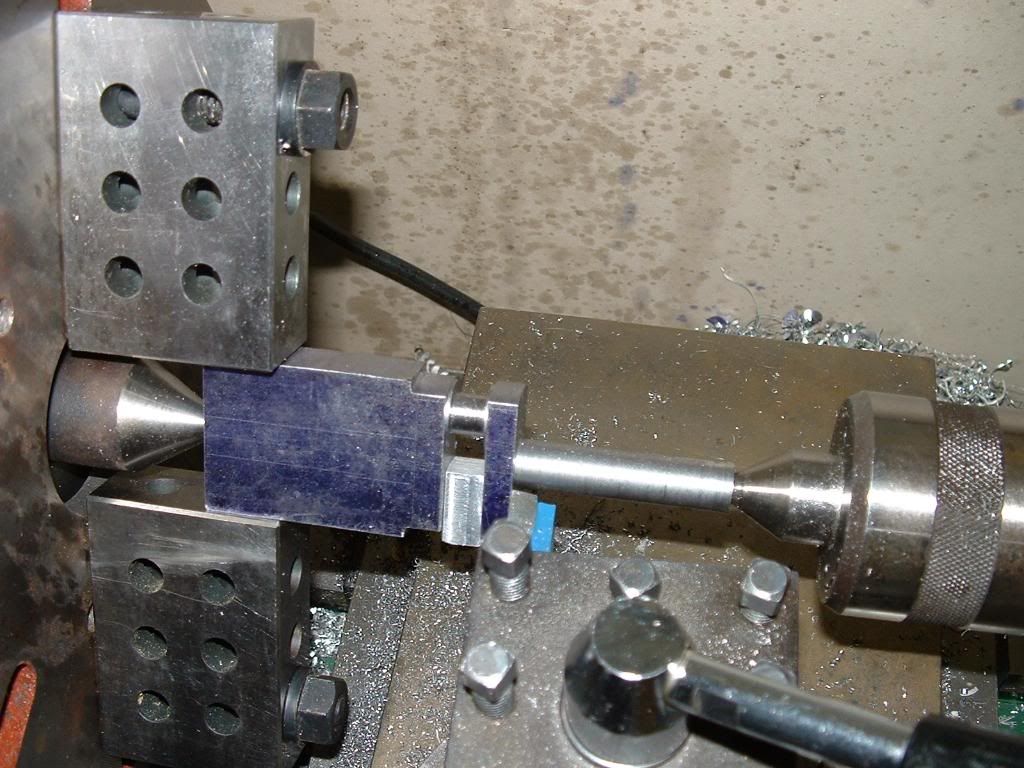

Now lets remove some extra material on the bad saw

And we get a crankshaft on diet

Back on the lathe

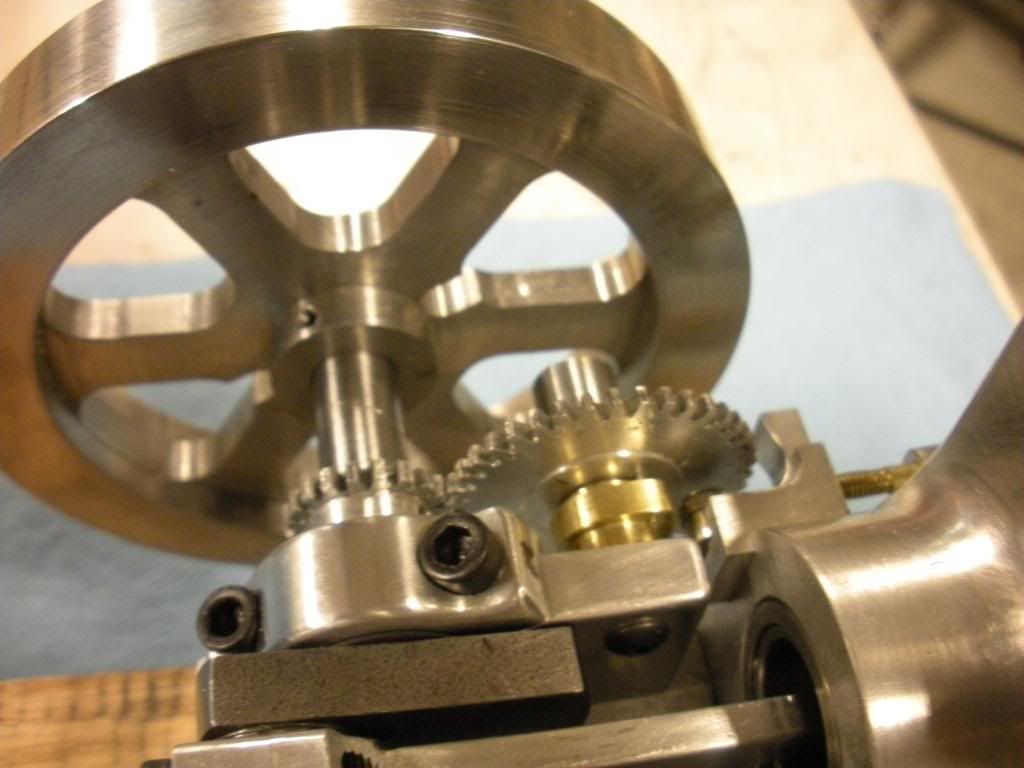

Next shot shows a few internal parts and blanks for the gears and the cam. In the from, there is a graphite gear I made to practice on.

For those interested in cutting their own gears, I used a hubbing technique found on the net

Sorry for the German language, yo ucan use Google translation if needed (I did use it) but images are worth thousand words they say!

http://www.metallmodellbau.de/GEAR-CUTTING.php

Here is an other web site on the topic

http://helicron.net/workshop/gearcutting/

This experience can be very frustrating but very rewarding at the end when you get meshing gears that work! How to spend 20 hours on something that sells for 8$ each ???

Here are some misc parts: carburetor, completed spark plug, muffler and regulator bobbin.

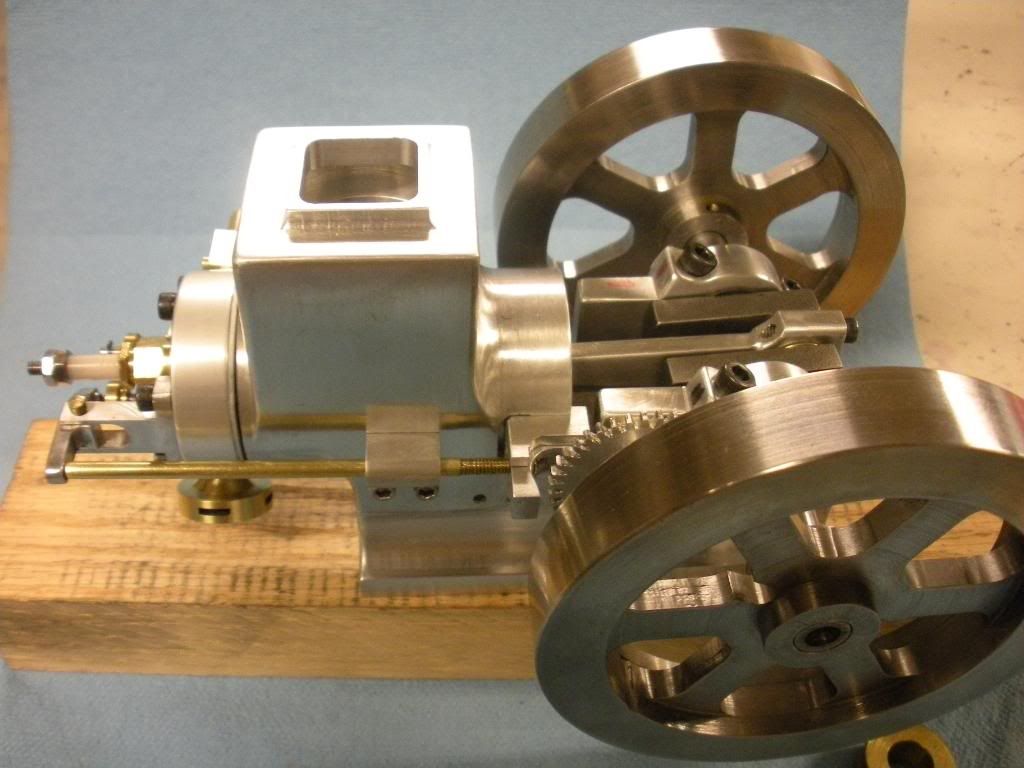

This is where I am at right now, as from yesterday

A shot from the front

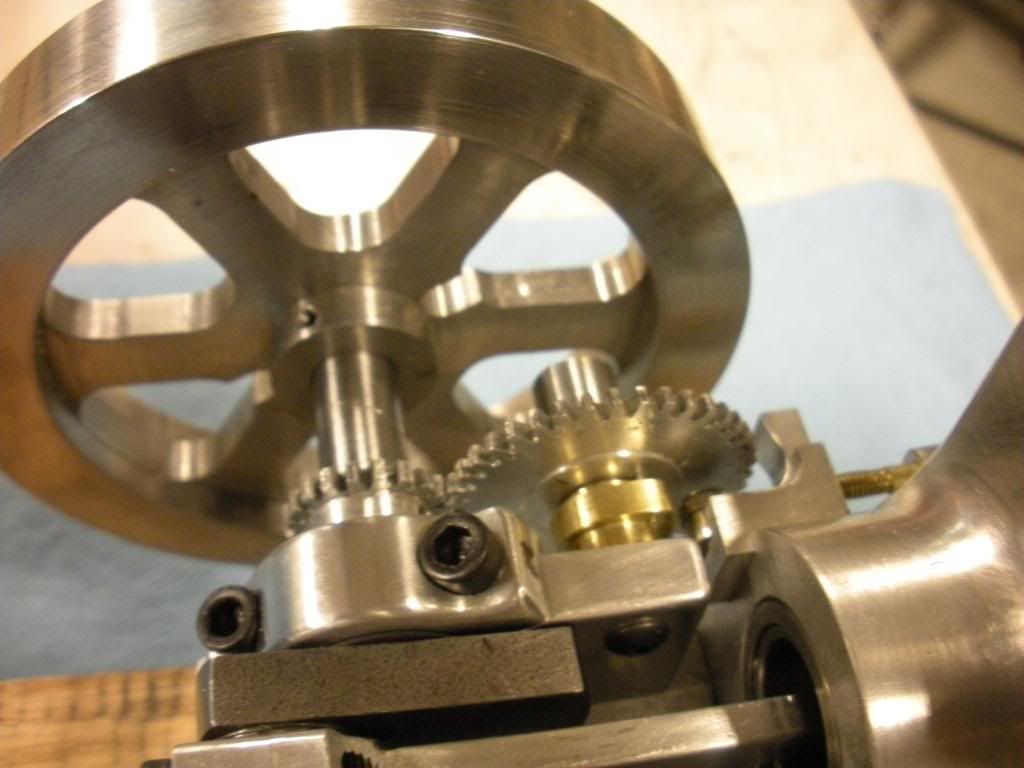

A close-up on the timing gears and cam. It works !

There is still a lot to be done like springs, points, regulator, rings heat threating, valve seats polish (again) and so on. Someday I'll get it done, just hope it will fire up.

Denis

It has been put aside many time to move other projects forward.

It is a design from David Kerzel , FL which was available for download at that time but seems no longer to be. Many thanks again to David for sharing his top quallity drawings with the community on the other forum ...

The engine is .75" bore x 0.8" stroke, water cooled jacket around cast iron sleeve / piston. All parts made from bar stock.

Here we go.

First thing done were the flywheels which took tremedous amount of time as they were first cut from a plate then turned. Cutting operation itself took the most time on my taiwanese band saw.

Next was a fairly simple part, the base unit.

Then some challenge and lots of filing practice ...

Now time for some very small parts, the head the valves , assembled spark plug.

The spark plug insulator was made from Corian, a real best to work with specially when drilling 1/32" x 1-1/4" hole :bow:

A few more parts and a first pre-assembly

Then came my first experiment to make a long crankshaft from a solid bar

Please no comments on the Dog used ! Had to use what I had on hand.

Now lets remove some extra material on the bad saw

And we get a crankshaft on diet

Back on the lathe

Next shot shows a few internal parts and blanks for the gears and the cam. In the from, there is a graphite gear I made to practice on.

For those interested in cutting their own gears, I used a hubbing technique found on the net

Sorry for the German language, yo ucan use Google translation if needed (I did use it) but images are worth thousand words they say!

http://www.metallmodellbau.de/GEAR-CUTTING.php

Here is an other web site on the topic

http://helicron.net/workshop/gearcutting/

This experience can be very frustrating but very rewarding at the end when you get meshing gears that work! How to spend 20 hours on something that sells for 8$ each ???

Here are some misc parts: carburetor, completed spark plug, muffler and regulator bobbin.

This is where I am at right now, as from yesterday

A shot from the front

A close-up on the timing gears and cam. It works !

There is still a lot to be done like springs, points, regulator, rings heat threating, valve seats polish (again) and so on. Someday I'll get it done, just hope it will fire up.

Denis