hello!

I was asking myself of there is anybody who making machines for hobby?

Because the most people have metalworking machines on this forum,

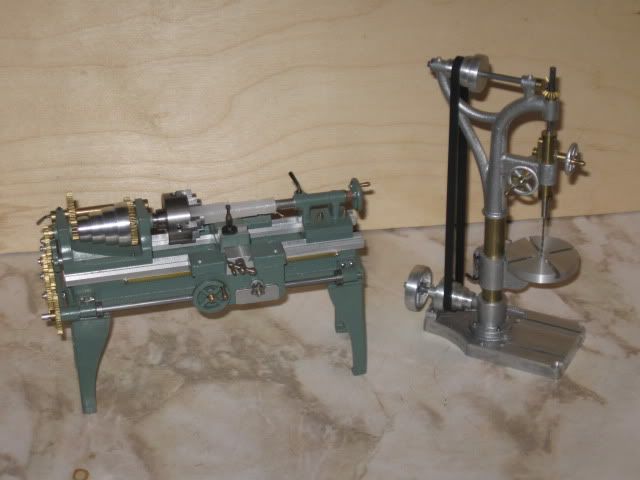

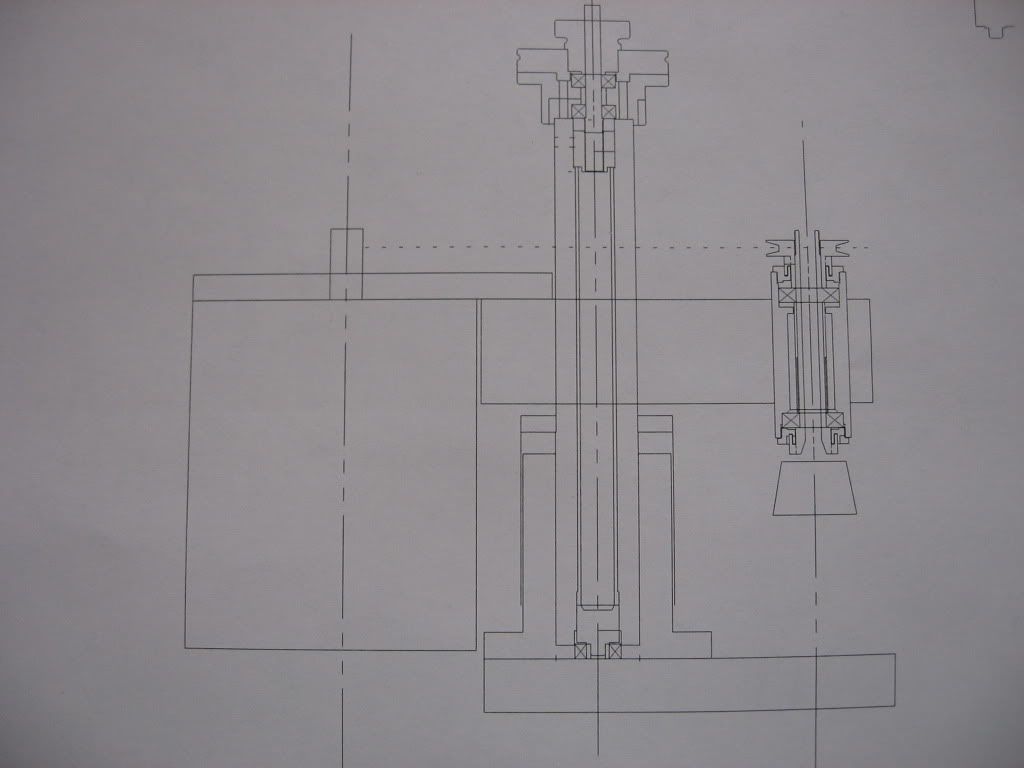

Is there a hobby in making machines? or scale machines?

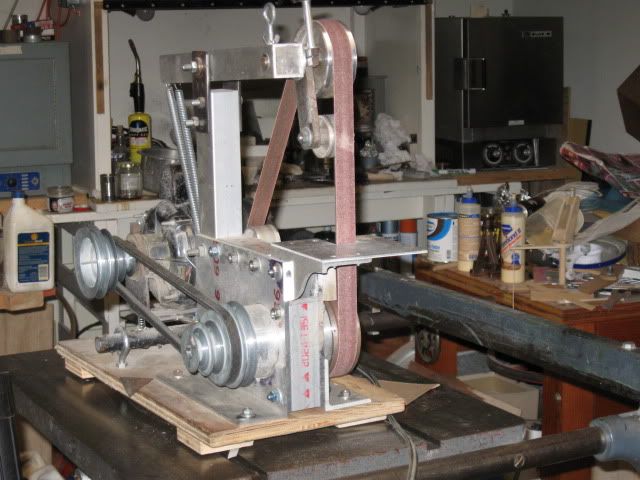

I saw on google example homemade engraving machines and homemade motorized hacksaw machines, so i was thinking,

maybe is there people who make machines like milling machines or mini lathes for fun?

greetings!

I was asking myself of there is anybody who making machines for hobby?

Because the most people have metalworking machines on this forum,

Is there a hobby in making machines? or scale machines?

I saw on google example homemade engraving machines and homemade motorized hacksaw machines, so i was thinking,

maybe is there people who make machines like milling machines or mini lathes for fun?

greetings!