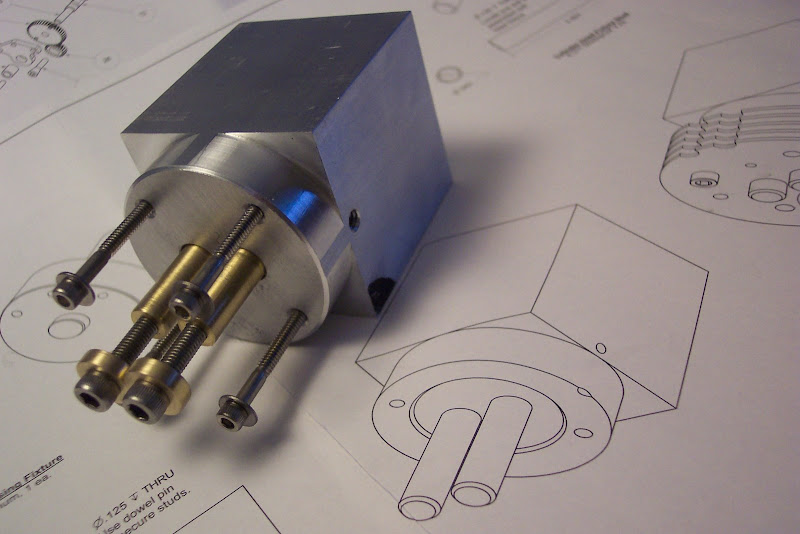

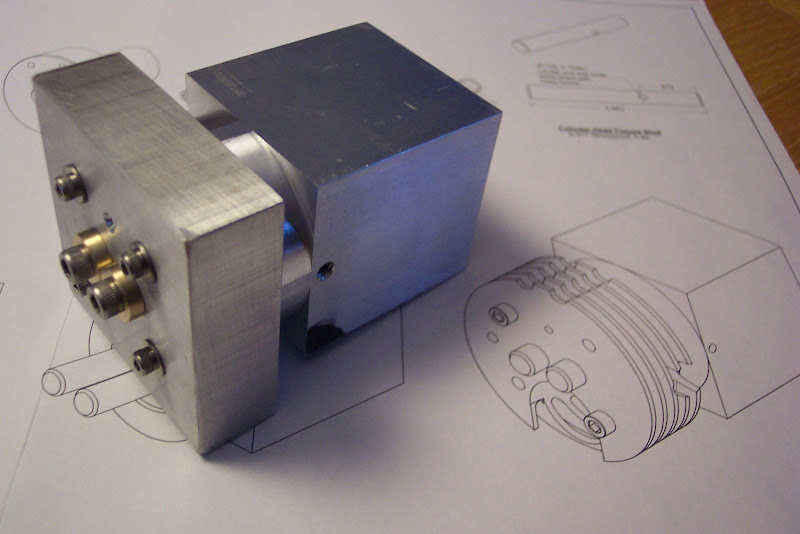

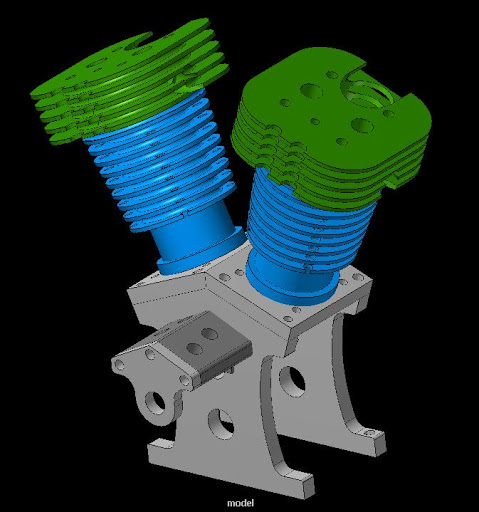

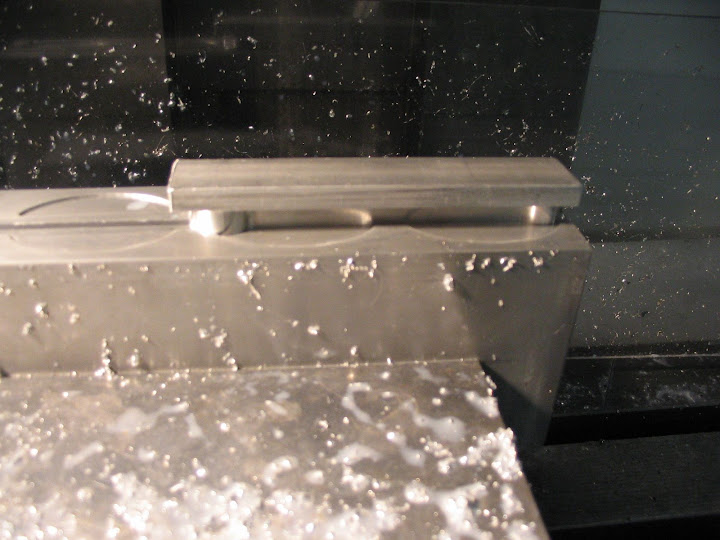

got a few jigs made;

Jig for holding the head while it endures several machinig set-ups.

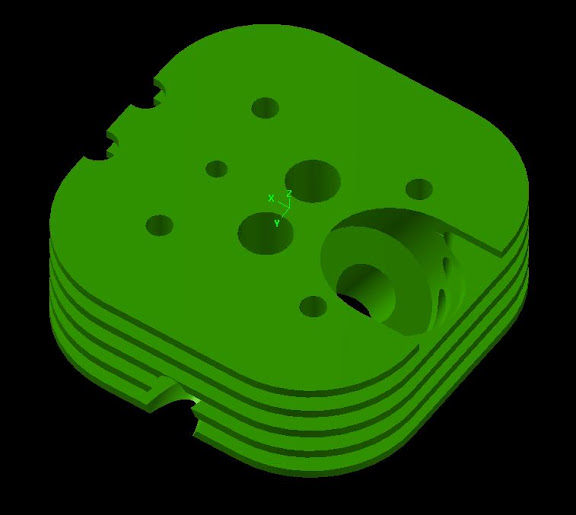

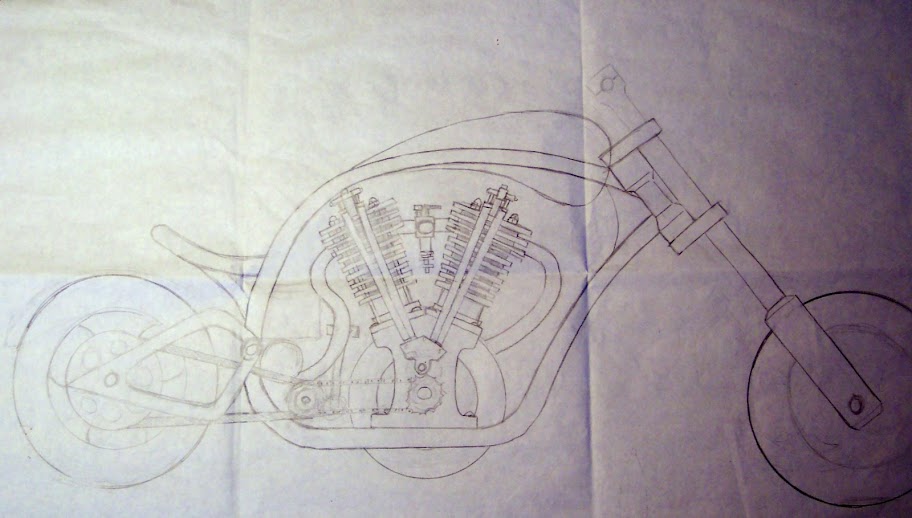

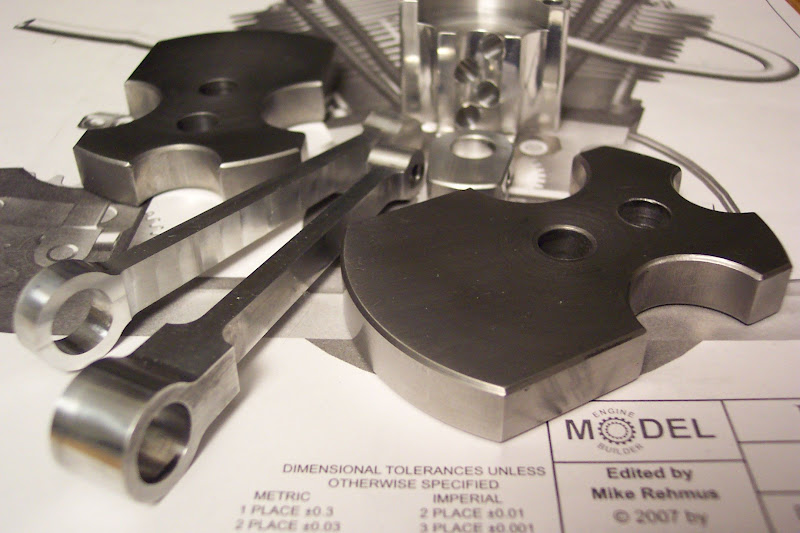

hopefully what it will look like after machining;

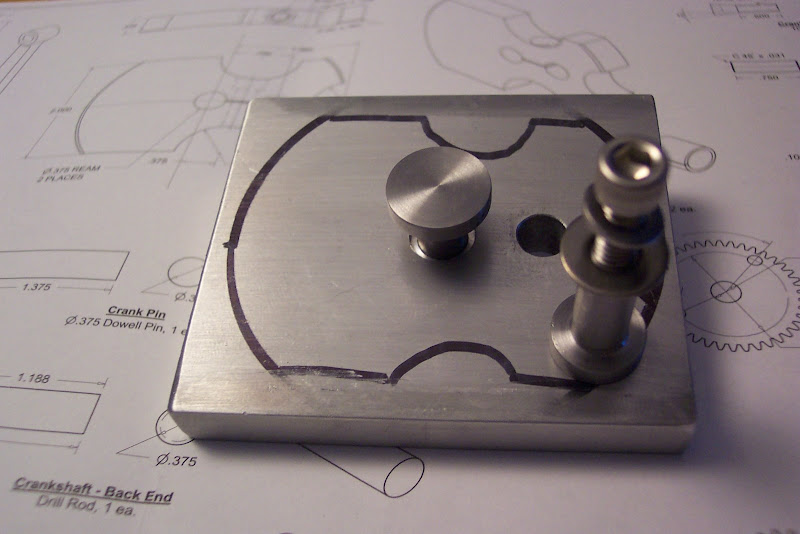

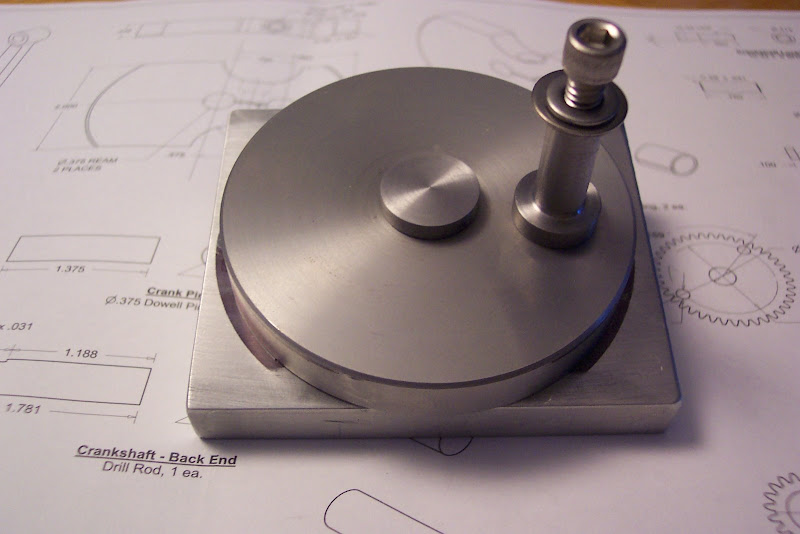

A jig for holding the crank webs;

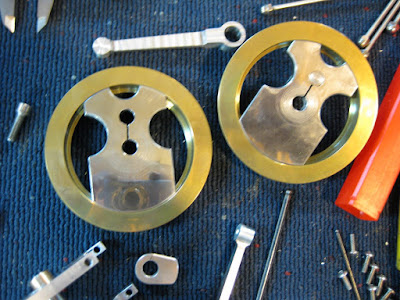

After the second hole is drilled and reamed, I will insert the second locating pin, secured from below with a capscrew;

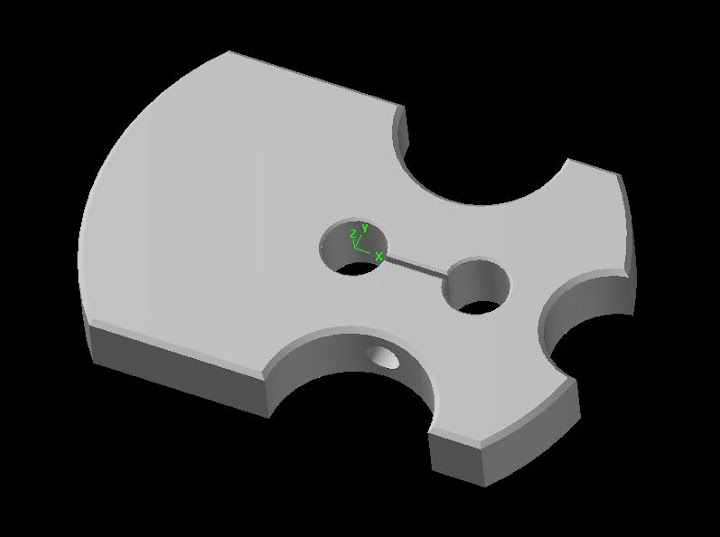

And what it might look like;

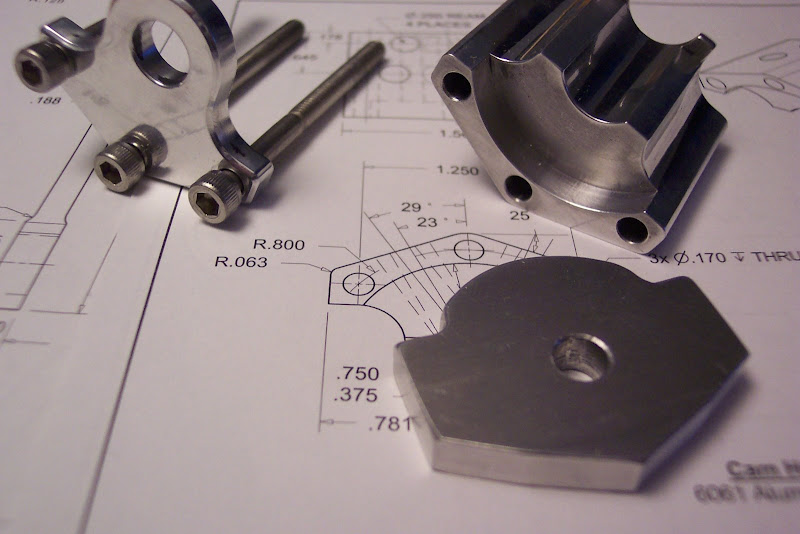

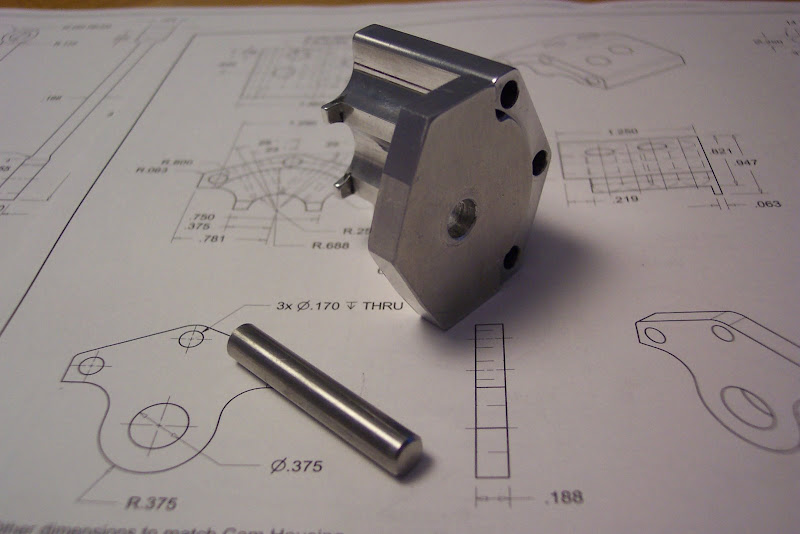

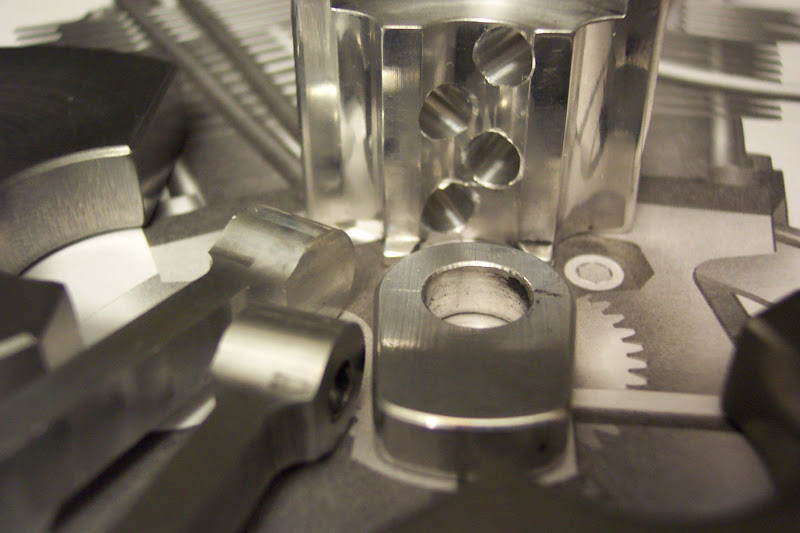

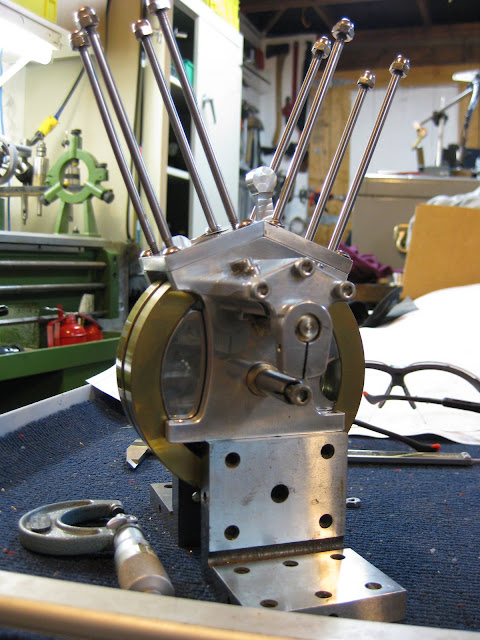

I made an angled plate to set up the cam housing to ream the holes for the cam followers; ( I do not have a dividing head)

The jig will be located with a pin in the face of a soft jaw in the vise. The centre of the pin will be X.Y. 0.00, Using an adjustable parallel

I plan on taking up the slack until the required angle is securely parallel to the bottom of the vise.

This will set the cam housing to the correct angle and repeated three more times until the axes of all holes meet at the centre of the locating pin.

Clear as mud? Hoefully the WIP pics explain it better.

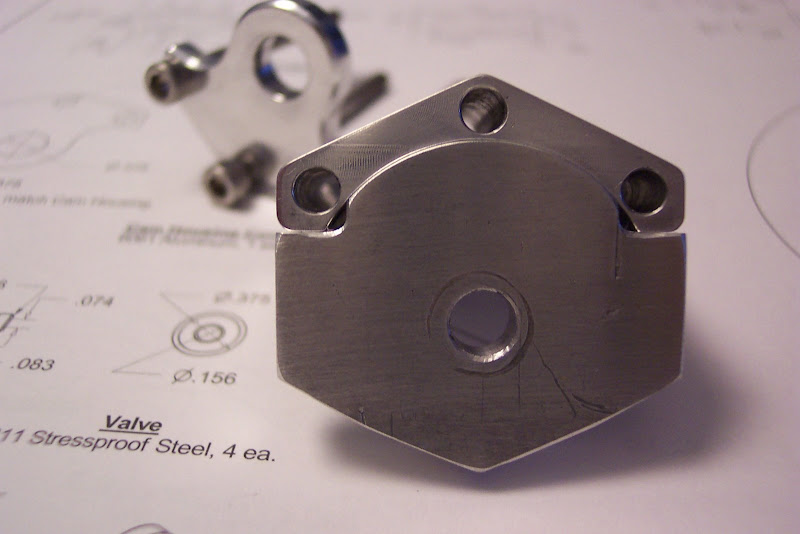

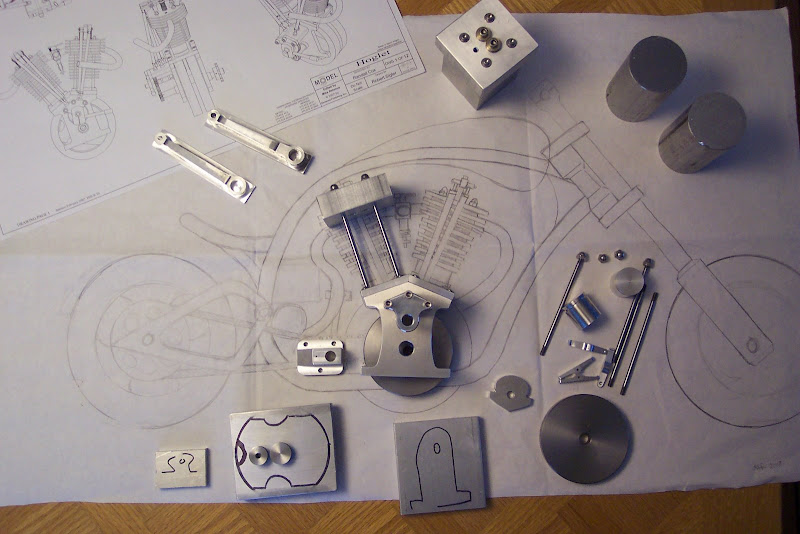

Where I am at so far;

I plan on building a SS frame as a display stand and hopefully down the road add some more moving parts.

Ciao for now.

-Kevin.