You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hoglet started (and running!)

- Thread starter kustomkb

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 14, 2007

- Messages

- 1,181

- Reaction score

- 31

Thanks Philly MatiR and Chuck.

I also have a honeydo/home improvement list but the foot had to come down and designate some me time.

After work I went to an O-ring distrubutor (with the engine, as Marv suggested) Whom I called before hand to see if they had counter sales, "sure no problem" , "So I can pop by and pick up a couple of O-rings" , "Absolutley"

I get there, ask for said O-rings, "what for ?" , show engine, "Oh theres a 25 dollar minimum."

So if anybody needs viton 020 O-rings, no problem.

My debit card didnt work. Gave them my last 25 dollars cash.

Go next door to get my E-clips, Show engine, "Here, take the whole bag!" "just bring it back when you get it running"

(gave them 1.50 I had in the car)

They will get my business and a recomendation. The other power tripping clown won't be seeing me again.

Rant over, Also if anybody is considering this build I would be happy to lend out any fixtures I have made.

(there's enough parts as it is!)

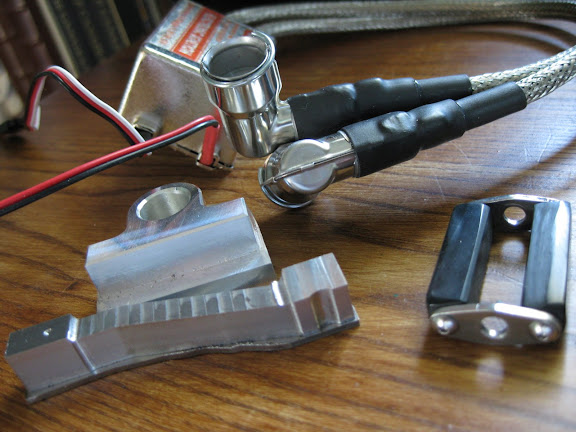

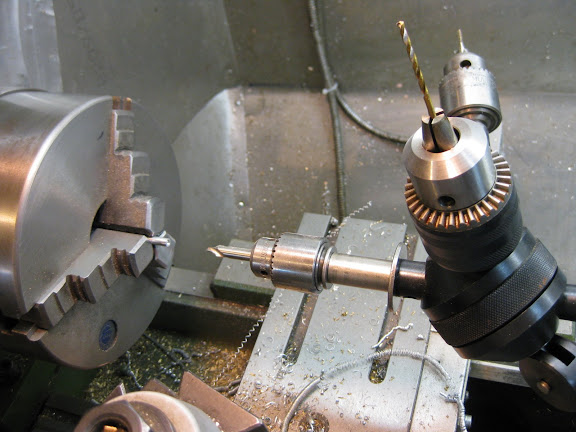

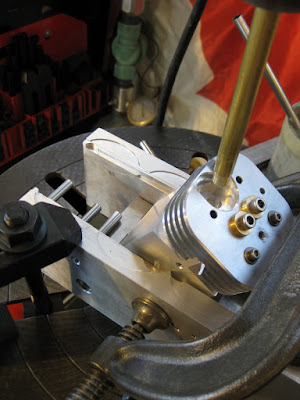

So, got the push rods done. Used my tailstock turret to drill and tap one end;

Also reamed the other end. To set depth of reamer I set up the back end of a boring bar to touch the drill chuck face. zero . move over depth, drill till chuck hits but end again.

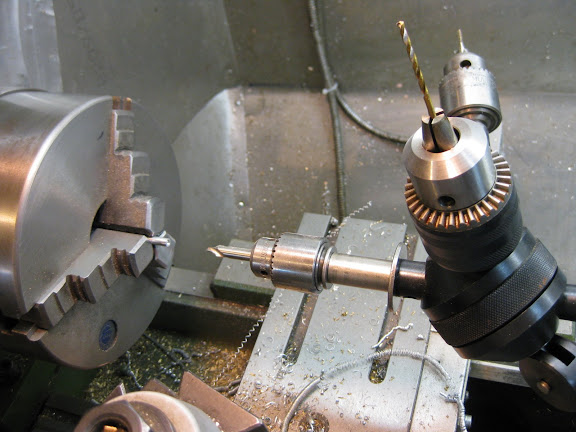

I also got he rods and pistons reamed and fitted;

Have a great long weekend, should be around, Eh.

I also have a honeydo/home improvement list but the foot had to come down and designate some me time.

After work I went to an O-ring distrubutor (with the engine, as Marv suggested) Whom I called before hand to see if they had counter sales, "sure no problem" , "So I can pop by and pick up a couple of O-rings" , "Absolutley"

I get there, ask for said O-rings, "what for ?" , show engine, "Oh theres a 25 dollar minimum."

So if anybody needs viton 020 O-rings, no problem.

My debit card didnt work. Gave them my last 25 dollars cash.

Go next door to get my E-clips, Show engine, "Here, take the whole bag!" "just bring it back when you get it running"

(gave them 1.50 I had in the car)

They will get my business and a recomendation. The other power tripping clown won't be seeing me again.

Rant over, Also if anybody is considering this build I would be happy to lend out any fixtures I have made.

(there's enough parts as it is!)

So, got the push rods done. Used my tailstock turret to drill and tap one end;

Also reamed the other end. To set depth of reamer I set up the back end of a boring bar to touch the drill chuck face. zero . move over depth, drill till chuck hits but end again.

I also got he rods and pistons reamed and fitted;

Have a great long weekend, should be around, Eh.

- Joined

- Dec 14, 2007

- Messages

- 1,181

- Reaction score

- 31

Made the CI sleeves this morning.

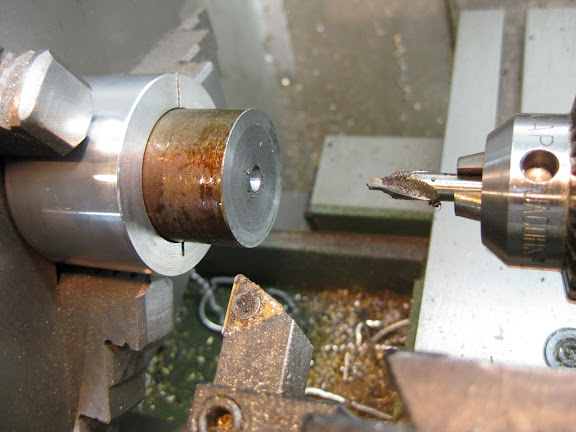

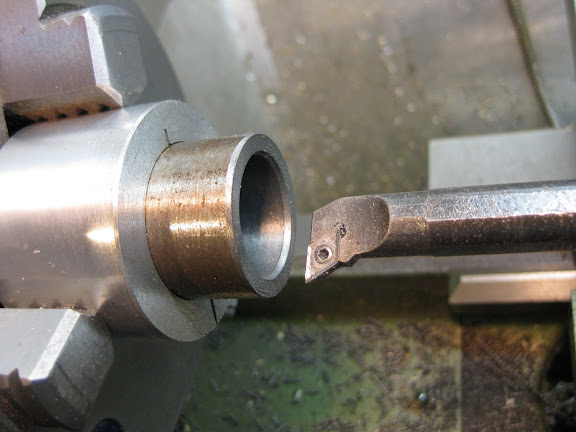

Centre drilled and drilled;

Then bored to leave a thou' for honing which will be closer to 2 thou' after installation. Then put a 30 deg. bevel on for turning between centres;

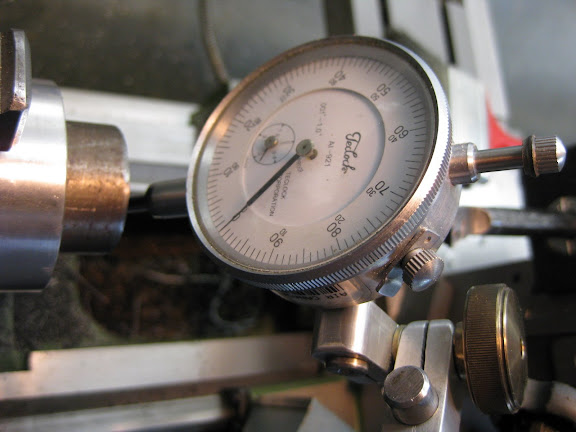

Then flipped it around to bevel the other end after clocking it in;

Checked my trusty hardened dead centre and it was less than a thou';

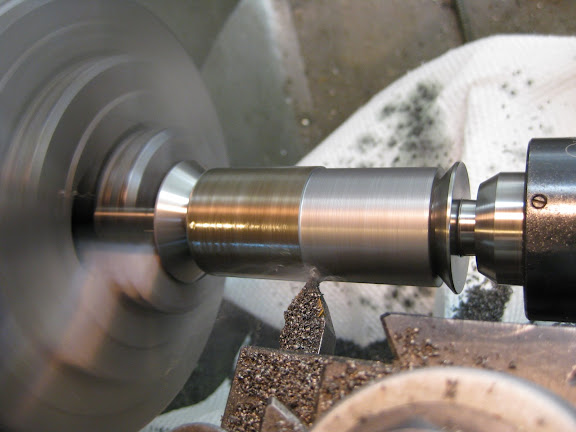

Stuffed a wet rag in the bore to eliminate chatter due to the thin wall;

turned between centre's to leave a thou press fit;

Then relieved 5 thou in a few spots to decrease the resistance during installation and to retain loc-tite;

Finally faced them to length from the top end to remove the bevel;

2 sleeves ready to install after preping some tooling to keep it all straight;

- Joined

- Dec 14, 2007

- Messages

- 1,181

- Reaction score

- 31

Thanks Bob,

I usually make a close fitting pilot with a squared base which is wider than the piece being pressed and a shoulder to control press depth. (flush/below) If everything is locked in square its hard to go wrong. And both pieces are protected from distortion.

At home its the big pipe fitters vise with two AL plates to squeeze between.

In the past I have used liquid nitrogen to shrink parts, not having access to that anymore I tried the heating method as with the flywheels and was very happy with the results. A hundred degrees makes a big diffrerence.

KB

- Joined

- Dec 14, 2007

- Messages

- 1,181

- Reaction score

- 31

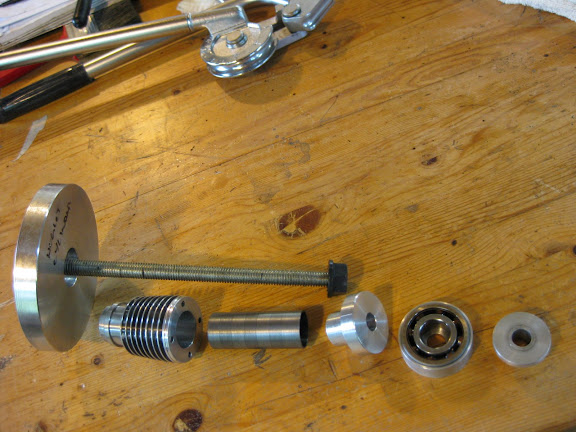

I set up some tooling to press in my sleeves,

Threaded base from my drill jig, ready rod, guide sleeve and thrust bearing;

Cylinders went in the barbeque to 450 deg;

And then the mad rush to crank them in;

[ame]http://www.youtube.com/watch?v=PbKiqeWPG_A[/ame]

Sleeve installed and a quick pass on some 600 paper to see where we are at;

- Joined

- Dec 14, 2007

- Messages

- 1,181

- Reaction score

- 31

Thanks alot boys!

I just checked in and that really made my day.

That's a technique from the aircraft days, couldn't just throw a 747 on the Bridgeport to open up a bore.

;D

Now off to paint the kitchen while the wife's away.

(I could use the brownie points)

- Joined

- Dec 14, 2007

- Messages

- 1,181

- Reaction score

- 31

I ended up purchasing 2 feet of 3/8, 2 feet 1/2 and 1 foot of 1 inch diameter of 1144 stessproof for the valves and cam for 30 dollars delivered from online metals.

C and H sales doesn't seem to have a website anymore. I'm having a hard time finding a suitable clutch /sprocket. Does anyone know an alternate source? or what they are used on.

I am considering modifying a bicycle freewheel or pressing a one way bearing into a sprocket.

I also still need to get the gears.

Thanks,

Kevin.

EDIT;

I found it, they are now http://www.candhsurplus.com/ They have an ebay store with a couple of items.

C and H sales doesn't seem to have a website anymore. I'm having a hard time finding a suitable clutch /sprocket. Does anyone know an alternate source? or what they are used on.

I am considering modifying a bicycle freewheel or pressing a one way bearing into a sprocket.

I also still need to get the gears.

Thanks,

Kevin.

EDIT;

I found it, they are now http://www.candhsurplus.com/ They have an ebay store with a couple of items.

MatiR

Well-Known Member

- Joined

- Jul 10, 2007

- Messages

- 65

- Reaction score

- 7

kustomkb said:C and H sales doesn't seem to have a website anymore. I'm having a hard time finding a suitable clutch /sprocket. Does anyone know an alternate source? or what they are used on.

I also still need to get the gears.

Kevin: I have an extra clutch/sprocket unit as I bought two but have lost one of the four little springs which tension the ratchet. You're welcome to it. It might work with 3 springs or one could cobble a new one. I work at UBC so should be no problem to hand it over.

I got 2 of the gears from BC Bearing in New West 604-524-8505 but 26.90 for the gears cost 27.25 freight. The other gears, driveshaft sprocket and chain from Small Parts.

M.

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

I just saw the video of your putting the sleeve in. I like that kind of stuff. Very helpful to us (me) know-little-to-nothing-at-alls.

Speaking of which...maybe dumb question...but were the gloves needed? Just curious to know if there was a safety concern or sensitivity to material or tools.

Thanks!

Speaking of which...maybe dumb question...but were the gloves needed? Just curious to know if there was a safety concern or sensitivity to material or tools.

Thanks!

Zee,

The gloves were because the cylinder was hot. It is heated up to expand the bore and the sleeve is usually cooled to reduce the bore. This is a common way to "shrink fit" parts together. I am not calling this procedure here common, I found it very enlightening!

Sean

The gloves were because the cylinder was hot. It is heated up to expand the bore and the sleeve is usually cooled to reduce the bore. This is a common way to "shrink fit" parts together. I am not calling this procedure here common, I found it very enlightening!

Sean

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

After your reply I thought I must have missed something.

Like the answer!!!

Oh my. Well I'm embarrassed. Obviously I didn't read the entire thread. :hDe:

Went right to the video.

A great video by the way.

Thanks.

Like the answer!!!

Oh my. Well I'm embarrassed. Obviously I didn't read the entire thread. :hDe:

Went right to the video.

A great video by the way.

Thanks.

- Joined

- Dec 14, 2007

- Messages

- 1,181

- Reaction score

- 31

Yes it was very hot, I had the sleeves in the freezer but dry ice would have been better.

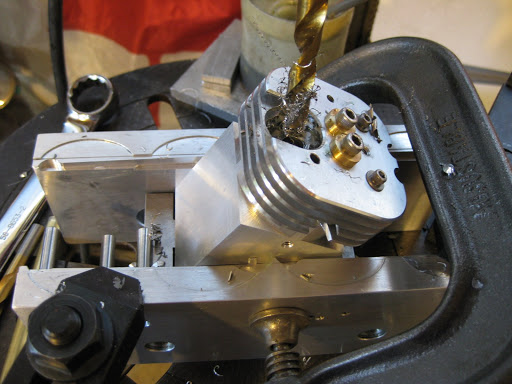

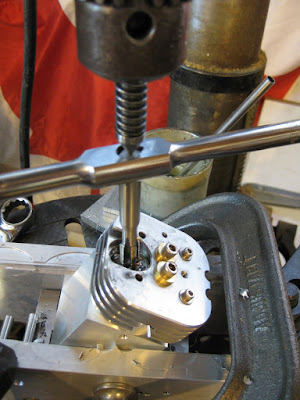

Got a metric fine tap for the spark plug holes.

Turned a dowel to pick up my pilot hole;

Then opened up to the TDS;

Then turned the other end down to pick up the new hole becuse I didn't leave enough room for the tap/handle; :-[

Then tapped it;

I also have playing with ideas for a "display stand";

View attachment HGLTAND FRAME.PDF

- Joined

- Dec 14, 2007

- Messages

- 1,181

- Reaction score

- 31

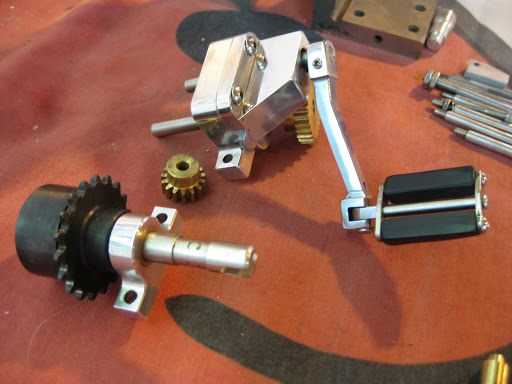

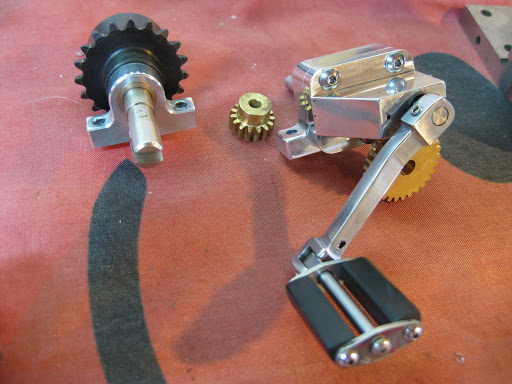

Got a little more work done on the kick starter;

Also recieved the sprag clutch and valve springs, Thanks Mati !!

And I got a little too excited drilling the pedal pivot hole;

That will have to be welded up and re-dressed.

KB

Similar threads

- Replies

- 12

- Views

- 836

- Replies

- 19

- Views

- 2K