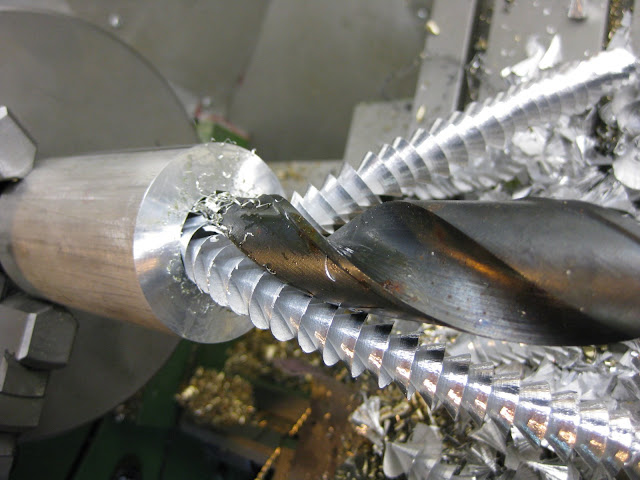

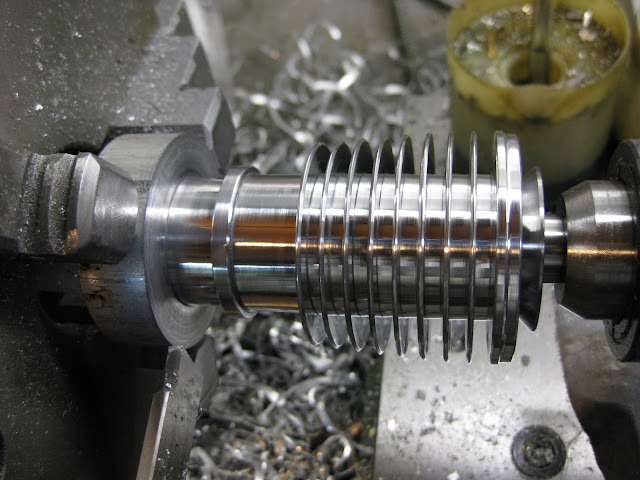

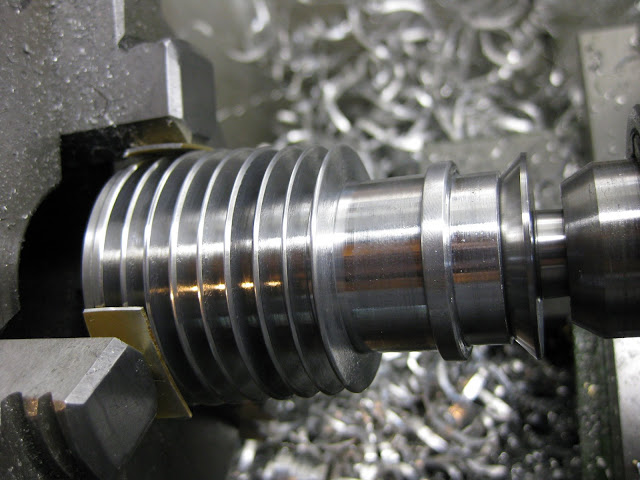

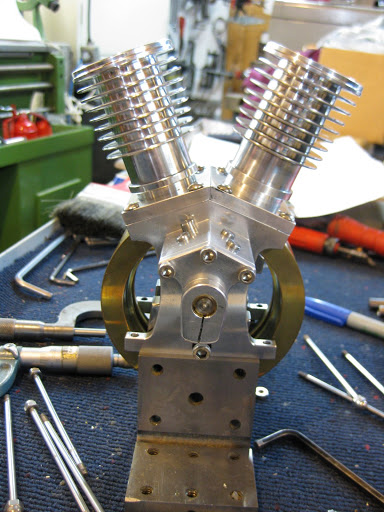

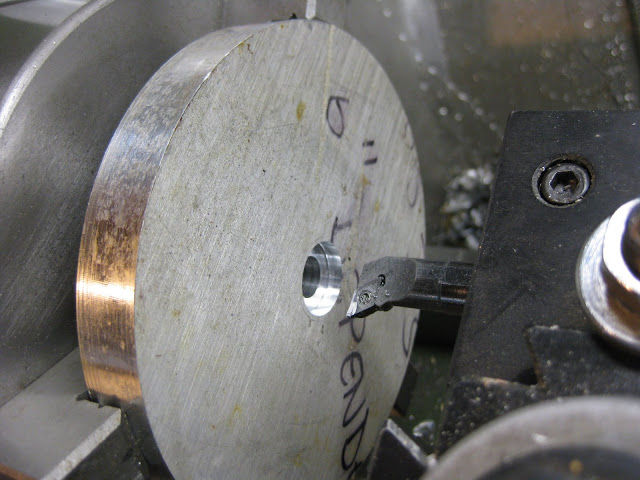

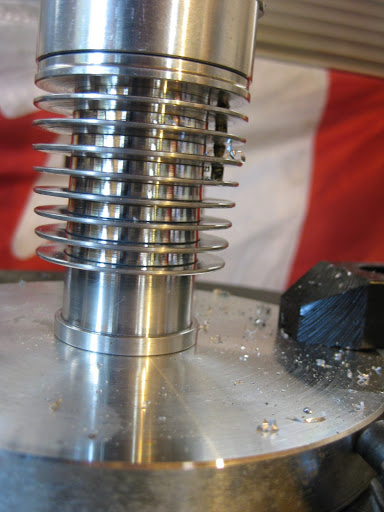

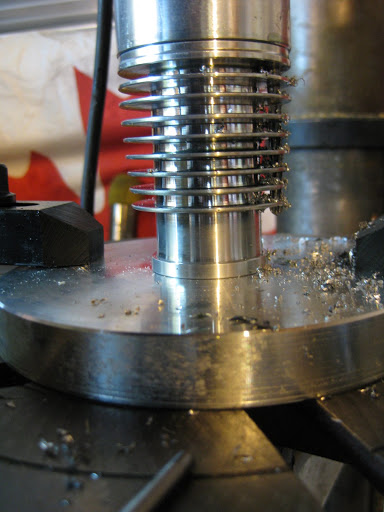

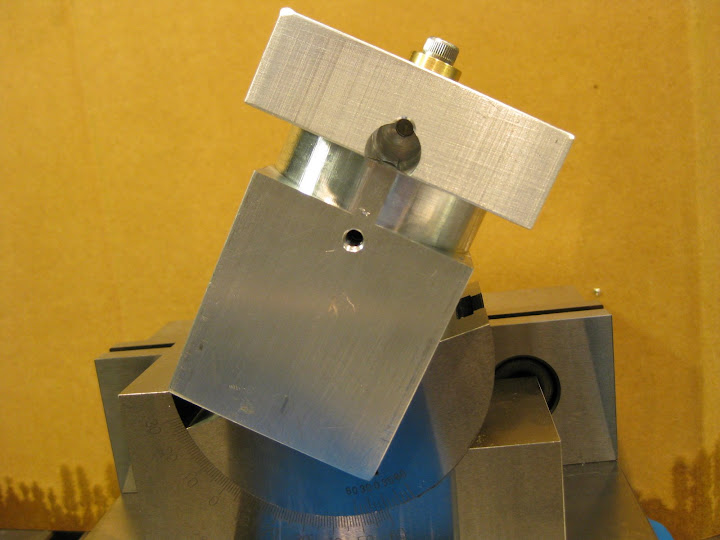

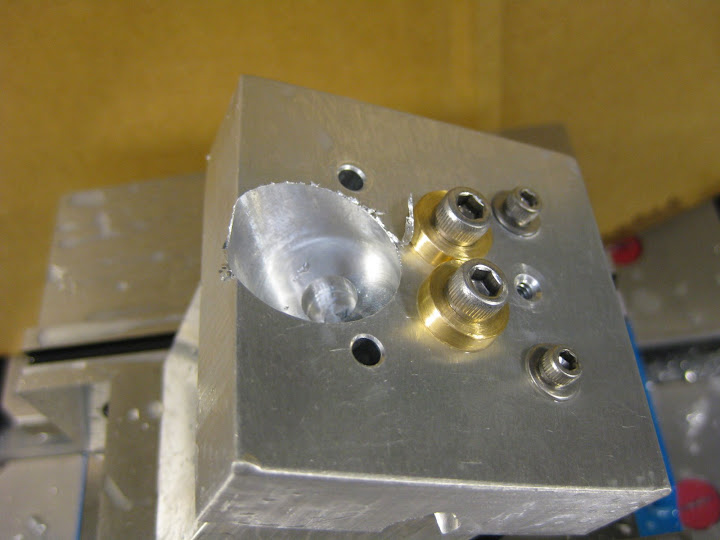

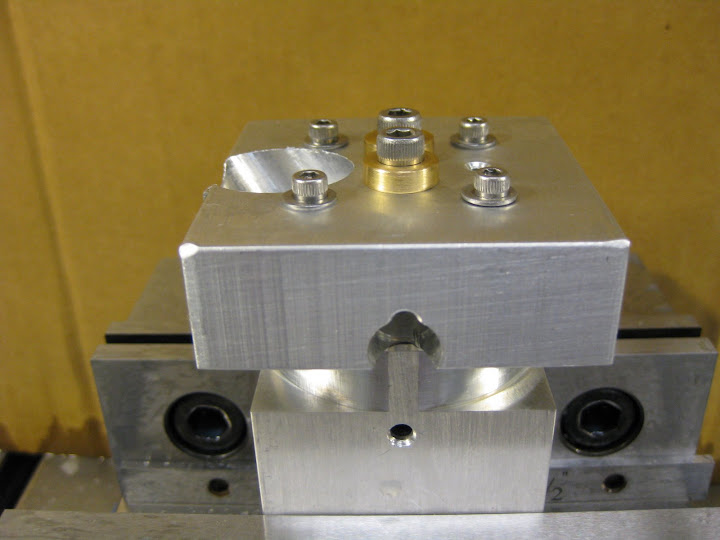

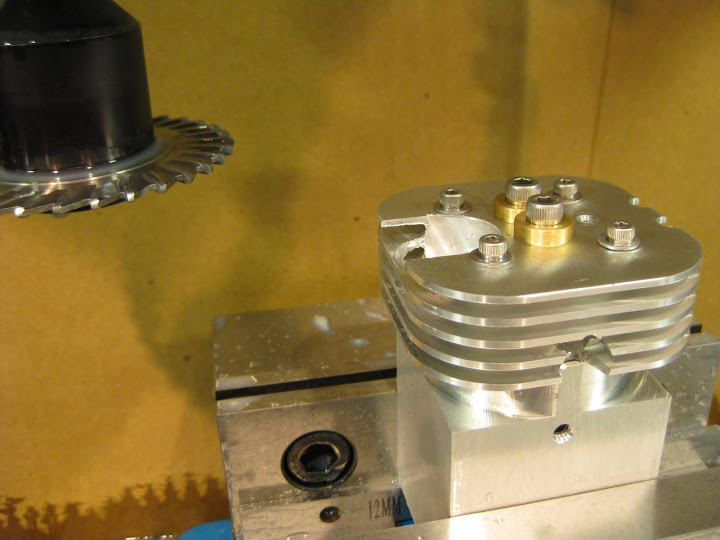

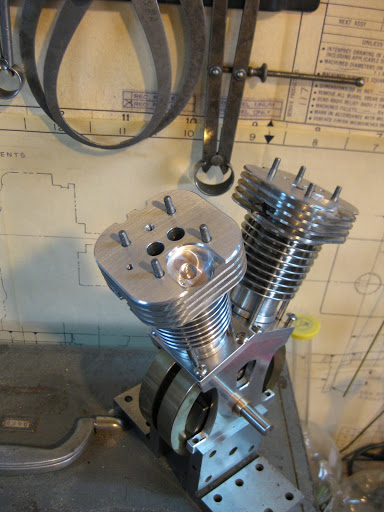

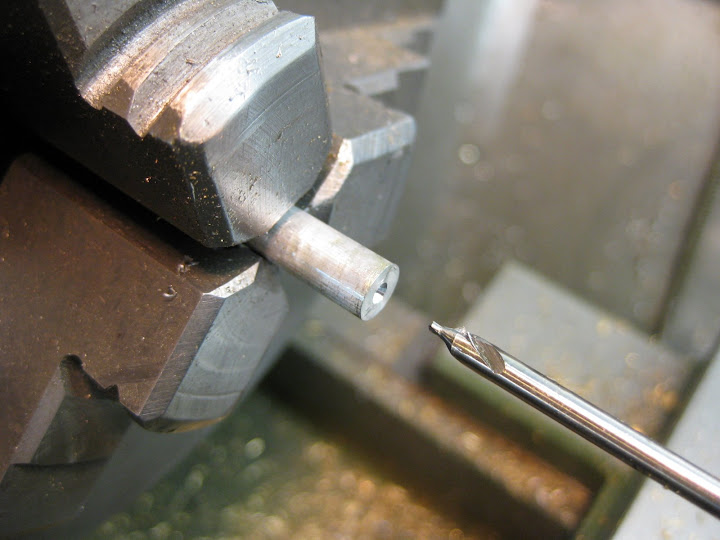

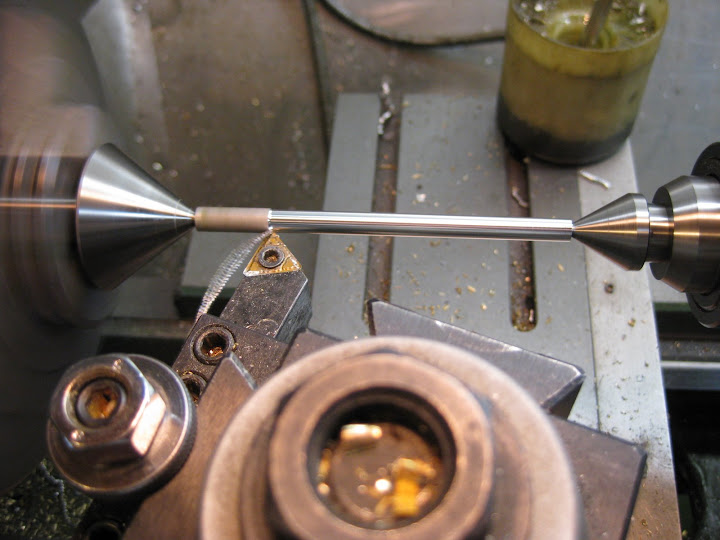

I opted to drill the holes before cutting the fins. There was a small amount of wander in a couple of the holes, I mostly solved this buy enlarging the holes by 0.5mm in all but the top fin so the heads would still be corectly located. One of the holes also needed a lick with a file just to pull it over a bit more.

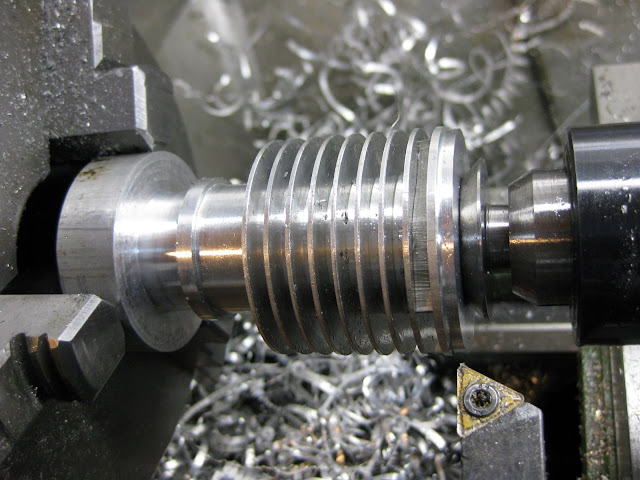

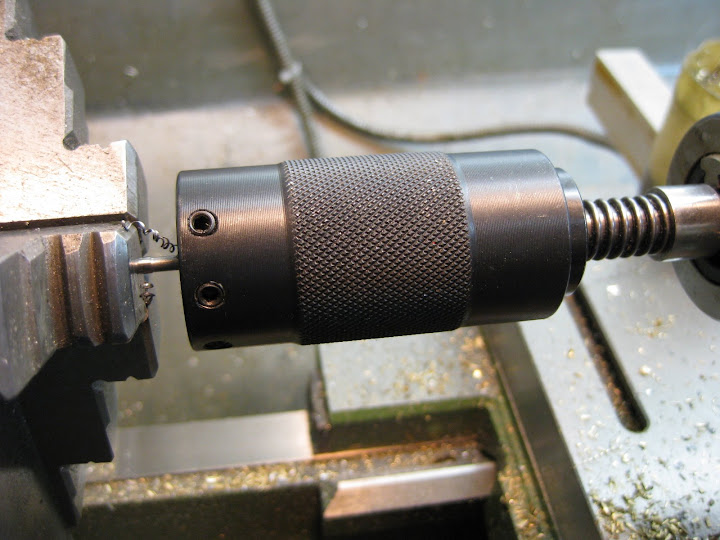

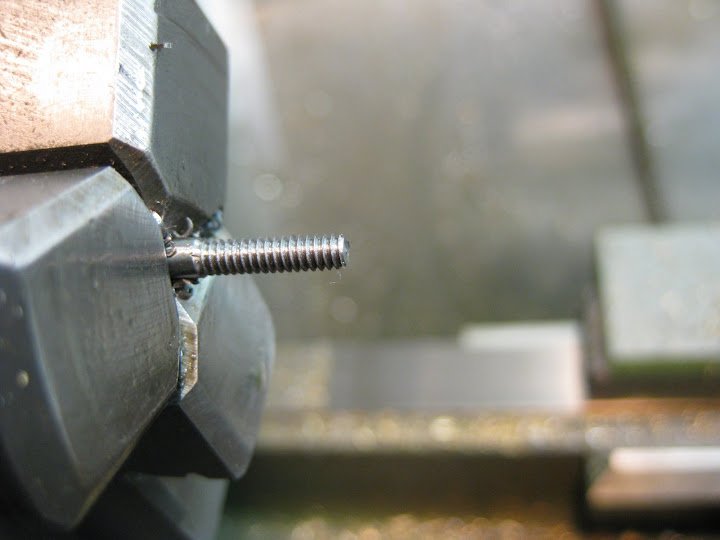

If I were doing it again I would start with a stub drill after the Ctr drill or cut the fins first and drill all the way with a 1/8" centre drill changing part way for a long series one, then open up to 4mm (I used M4 threads on 5/32 rod)

Jason

If I were doing it again I would start with a stub drill after the Ctr drill or cut the fins first and drill all the way with a 1/8" centre drill changing part way for a long series one, then open up to 4mm (I used M4 threads on 5/32 rod)

Jason