You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Good Lathe Deal from Enco

- Thread starter rake60

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

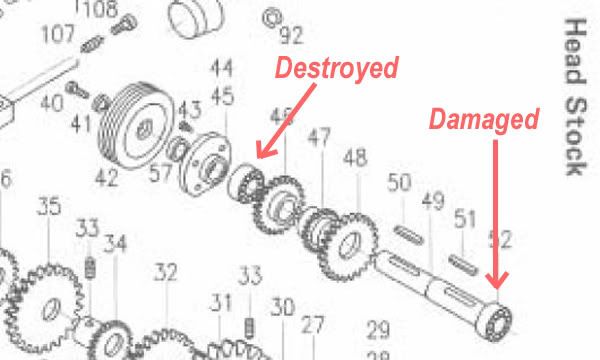

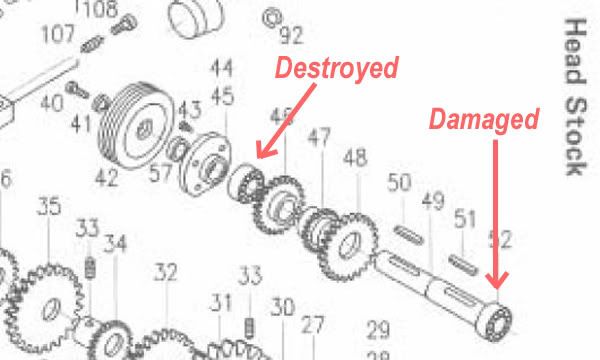

Wow! I bet the gearbox is full of swarf! Is this the main spindle bearing? Looks like the balls were soft!

rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 124

I don't think any of the debris actually got into the gearbox.

It was the outer bearing that blew up so most of the broken pieces were in the end cover.

I did run a magnet around the bottom of the gearbox but it came out clean.

Did you know the bottom of that side cover is about 1/2" below the oil level in the head stock.

I know it now! :

Also, that inner gear is too big to fit out the hole under that side cover.

Getting it off and back on the shaft takes both hands under the oil feeling for the key and keyway.

That was entertaining.

Rick

It was the outer bearing that blew up so most of the broken pieces were in the end cover.

I did run a magnet around the bottom of the gearbox but it came out clean.

Did you know the bottom of that side cover is about 1/2" below the oil level in the head stock.

I know it now! :

Also, that inner gear is too big to fit out the hole under that side cover.

Getting it off and back on the shaft takes both hands under the oil feeling for the key and keyway.

That was entertaining.

Rick

I've seen that type of damage before. One of the balls was defective. When it sheared off a splinter that splinter acted as a ramp twisting the bearing races as a ball rolled over it. It's like driving your car up on ramps so you can change the oil. In this case it was like putting the car up on ramps without any overhead clearance. Consequently the car flattened and pushed out the walls too. Due to the ramping effect the bearing became wider with the outside race pushing one way and the inner race going the other putting a huge load on the other bearing through the shaft wiping it out too. The balls all went like falling dominoes as more splinters and shards were produced from the pressures involved.

rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 124

jackfrost said:This is the poster child thread for: "DONT BUY A LATHE FROM ENCO !!"

I wouldn't go that far.

They did make it right in the end.

I did have a much better experience with Grizzly when I bought my G4000 9 X 19 lathe.

There were some problems with the spindle bearings, I talked to a real person on the very first

call and the problem was resolved with one call.

Rick

Mosey

Well-Known Member

How about inviting Enco to comment on their lathes, bearings, and warrantee for our site? They have always been good about issues for me.

That sounds like a chance for Enco to explain themselves. I have bought from them dozens of times

and never had a problem with their service when I needed to return something. Rick's experience

with the service dept. concerning this lathe would put me off them if I were a first time buyer. No

excuse for the situation in this thread!

and never had a problem with their service when I needed to return something. Rick's experience

with the service dept. concerning this lathe would put me off them if I were a first time buyer. No

excuse for the situation in this thread!

The only issue Dean, is that the lathe was bought for the place that Rick Works. I wouldn't want to generate any friction between Rick and his boss......other than that....I completely agree....They got some splainin to do Lucy!

Dave

Dave

rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 124

My boss has quite an negative view of Enco.

This purchase was his first major buy from them and they seemed to drop the ball at every turn.

I have had situations were I'd do something wrong, fix it and create a couple more wrongs in the process.

I have done that to both customers and bosses is the past.

This was the first Enco deal that I've ever had go so wrong, and I have bought a lot from them, personally

and for work related things.

I will invite them to comment, but would be very surprised to receive any type of response.

Rick

PS: I did send an email to Enco's customer service department extending an invitation for their comment.

We will see if there is any response to that.

This purchase was his first major buy from them and they seemed to drop the ball at every turn.

I have had situations were I'd do something wrong, fix it and create a couple more wrongs in the process.

I have done that to both customers and bosses is the past.

This was the first Enco deal that I've ever had go so wrong, and I have bought a lot from them, personally

and for work related things.

I will invite them to comment, but would be very surprised to receive any type of response.

Rick

PS: I did send an email to Enco's customer service department extending an invitation for their comment.

We will see if there is any response to that.

I will say this.

I have bought from several sources over the years, but major machinery, only from local industrial auctions were I could see the equipment, Harbor Freight ( i am lucky to have one 10 min from my house), and Grizzly.

Grizzly has by far the BEST customer service. I have had issues with delivery damage or bad parts for my Bandsaw, Mill/Drill and my G4003. In all cases Grizzly came through like a champ !

No questions asked. Either replacement parts were shipped out immediately, or arrangements to pick up a lathe (my first G4003 had a major casting crack under the bed), and delivery me a new one with lift gate service to my house for free.

That's how customer service should be. And please note. This my hobby. Not my livelyhood, so I can easily see how a business man that depends on his tools to generate revenue would be pissed.

I have bought from several sources over the years, but major machinery, only from local industrial auctions were I could see the equipment, Harbor Freight ( i am lucky to have one 10 min from my house), and Grizzly.

Grizzly has by far the BEST customer service. I have had issues with delivery damage or bad parts for my Bandsaw, Mill/Drill and my G4003. In all cases Grizzly came through like a champ !

No questions asked. Either replacement parts were shipped out immediately, or arrangements to pick up a lathe (my first G4003 had a major casting crack under the bed), and delivery me a new one with lift gate service to my house for free.

That's how customer service should be. And please note. This my hobby. Not my livelyhood, so I can easily see how a business man that depends on his tools to generate revenue would be pissed.

rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 124

It's like "deja vu all over again".

When we were originally having the problems with this lathe, Enco kept passing it on to

someone who could "better understated the problem and bring it to a resolution".

That would include the guy who was sure our amperage was too low. :wall:

I guess this request hasn't made it to the person who is willing to reply just yet. :

I'm just one voice.

If anyone else would like to ask them to reply, this is the address to send it to.

[email protected]

If they get enough requests maybe they will respond, but I doubt that will ever happen.

Please copy and paste a link to this thread in your email to them.

Rick

When we were originally having the problems with this lathe, Enco kept passing it on to

someone who could "better understated the problem and bring it to a resolution".

That would include the guy who was sure our amperage was too low. :wall:

I guess this request hasn't made it to the person who is willing to reply just yet. :

I'm just one voice.

If anyone else would like to ask them to reply, this is the address to send it to.

[email protected]

If they get enough requests maybe they will respond, but I doubt that will ever happen.

Please copy and paste a link to this thread in your email to them.

Rick

sunworksco

Rocket Man

- Joined

- Nov 20, 2010

- Messages

- 243

- Reaction score

- 13

Mr. Hurt:

Thank you for bringing this bulletin board thread to Encos attention we were unaware of this conversation taking place at the Home Model Engine Machinist website, and we welcome the opportunity to address any concerns regarding Encos products.

Ive reviewed the conversation thread at the, and I have to say that its pretty embarrassing. An internal review of events on our side of things shows that there were several errors made by Enco associates that just shouldnt have happened. Were working on getting those issues corrected, and we will also be working with Rake60 (Rick) to ensure that any outstanding issues that he may have regarding his bench lathe are addressed to his satisfaction.

For the record, Encos machinery warranty backs our machinery for 1 year on parts, 90 days labor. The complete details of our warranty can be viewed here: http://www.use-enco.com/CGI/INPAGE?PMPAGE=CustomerSupport/Terms.htm#warranty. Enco has been in business for over 70 years and we pride ourselves in delivering quality tools at the lowest guaranteed prices. If we ever disappoint you in any way, we would always appreciate the opportunity to speak with you and try to set things right.

If you have specific concerns or questions, please feel free to call/contact me at the email address or phone number below. Thank you again for bringing this to our attention, and I hope that we hear from you again soon!

Best Regards!

Doug Styes

Operations Manager, Enco

Toll Free: 800-873-3626, ext. 426501

Direct: 678-309-6501

Email: [email protected]

From this email:

Hello,

I was going to purchase your products but have decided to wait until your deaf ears are fixed !

http://www.homemodelenginemachinist.com/index.php?topic=17438.msg190173;topicseen#msg190173

Thank you for bringing this bulletin board thread to Encos attention we were unaware of this conversation taking place at the Home Model Engine Machinist website, and we welcome the opportunity to address any concerns regarding Encos products.

Ive reviewed the conversation thread at the, and I have to say that its pretty embarrassing. An internal review of events on our side of things shows that there were several errors made by Enco associates that just shouldnt have happened. Were working on getting those issues corrected, and we will also be working with Rake60 (Rick) to ensure that any outstanding issues that he may have regarding his bench lathe are addressed to his satisfaction.

For the record, Encos machinery warranty backs our machinery for 1 year on parts, 90 days labor. The complete details of our warranty can be viewed here: http://www.use-enco.com/CGI/INPAGE?PMPAGE=CustomerSupport/Terms.htm#warranty. Enco has been in business for over 70 years and we pride ourselves in delivering quality tools at the lowest guaranteed prices. If we ever disappoint you in any way, we would always appreciate the opportunity to speak with you and try to set things right.

If you have specific concerns or questions, please feel free to call/contact me at the email address or phone number below. Thank you again for bringing this to our attention, and I hope that we hear from you again soon!

Best Regards!

Doug Styes

Operations Manager, Enco

Toll Free: 800-873-3626, ext. 426501

Direct: 678-309-6501

Email: [email protected]

From this email:

Hello,

I was going to purchase your products but have decided to wait until your deaf ears are fixed !

http://www.homemodelenginemachinist.com/index.php?topic=17438.msg190173;topicseen#msg190173

Similar threads

- Replies

- 35

- Views

- 11K

- Replies

- 46

- Views

- 11K

- Replies

- 8

- Views

- 9K

- Replies

- 2

- Views

- 10K