- Joined

- Nov 14, 2009

- Messages

- 675

- Reaction score

- 104

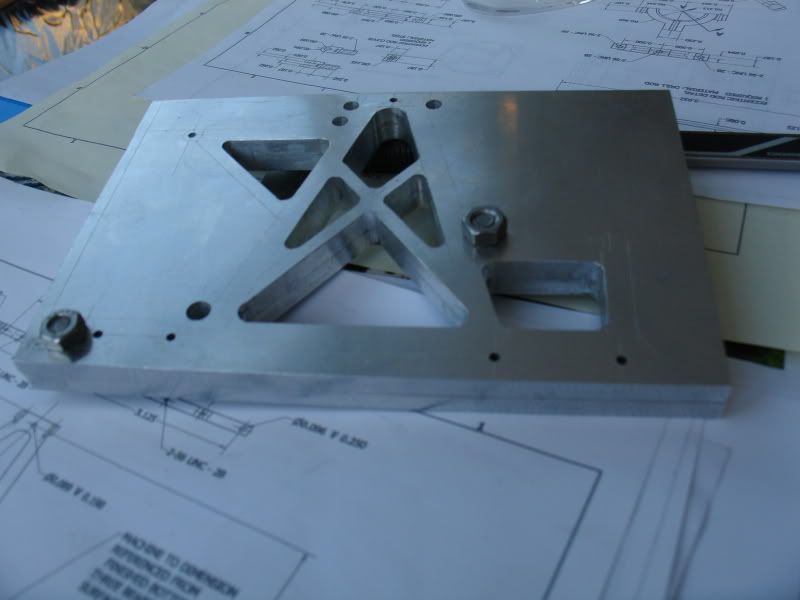

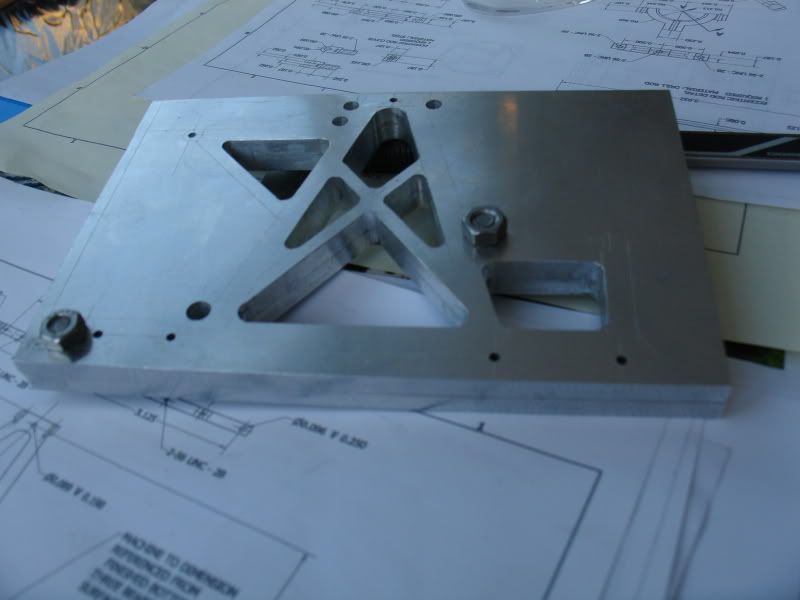

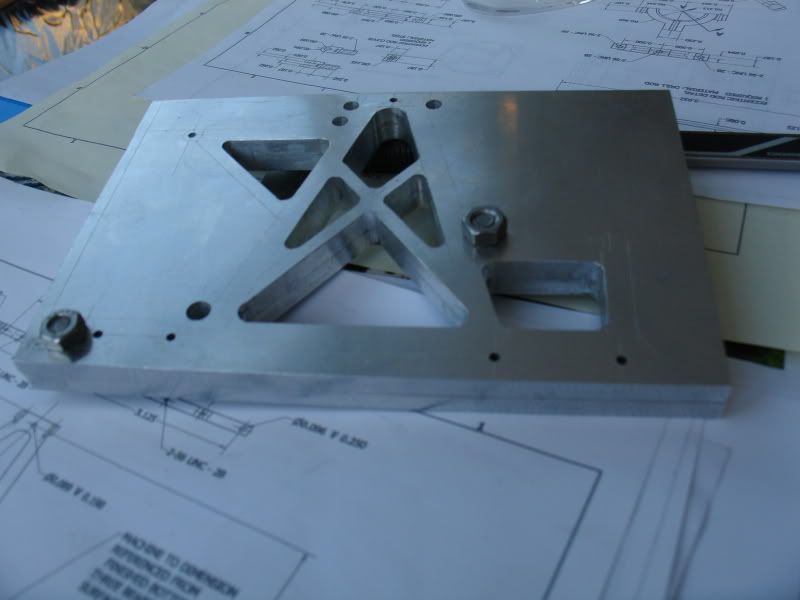

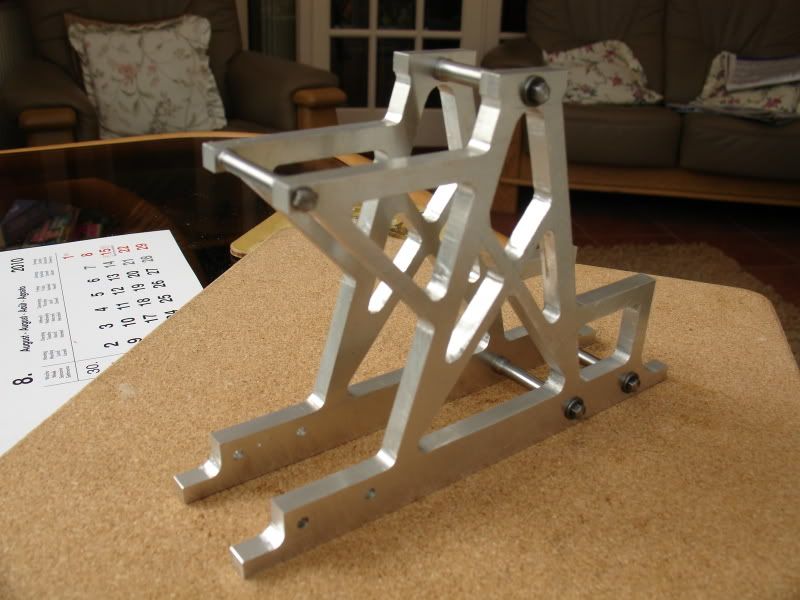

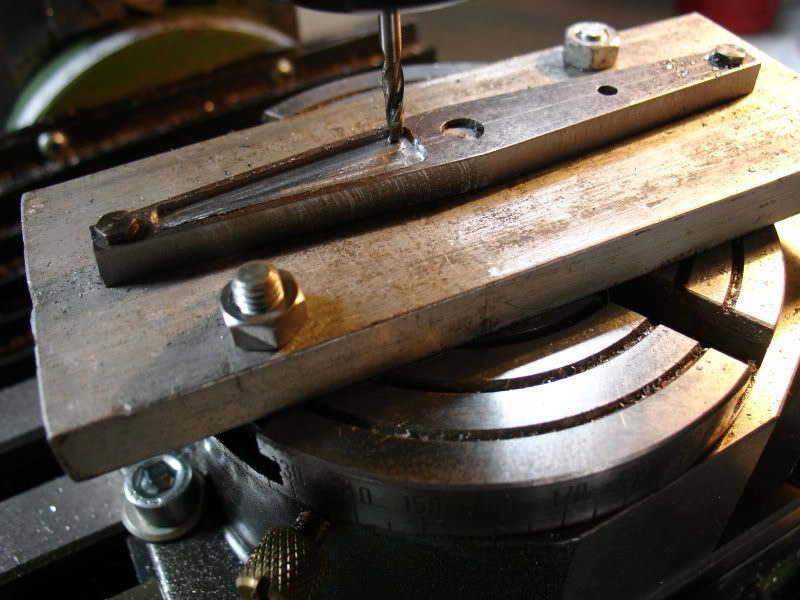

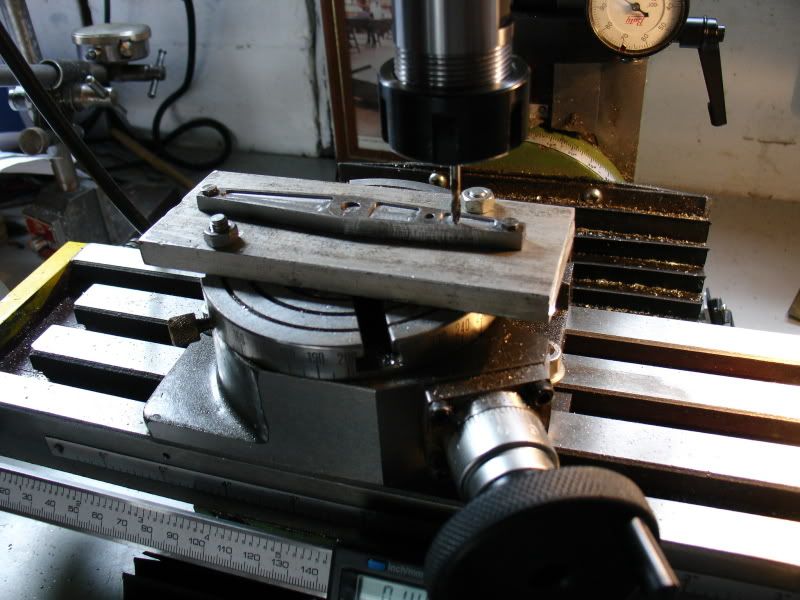

Here we go again,the start of another beam engine,made good use of my little miller on this one so far and not a CNC in sight.

Don

Don

Tell you how i did it Peter,I enlarged the drawing of the frame till it was full size and scaled the missing dimensions from the screen as I couldn't figure how to print out the page,those sizes were not important except to be in proportion.pmerritt said:Very nice work Don! Have you or any of you other builders drawn out the details of the side frames? That would be a big help to people like me who don't feel up to the challenge of figuring it out on our own

Peter

Enter your email address to join: