Metal Mickey

Well-Known Member

- Joined

- Jul 5, 2008

- Messages

- 612

- Reaction score

- 6

Thanks Bob.

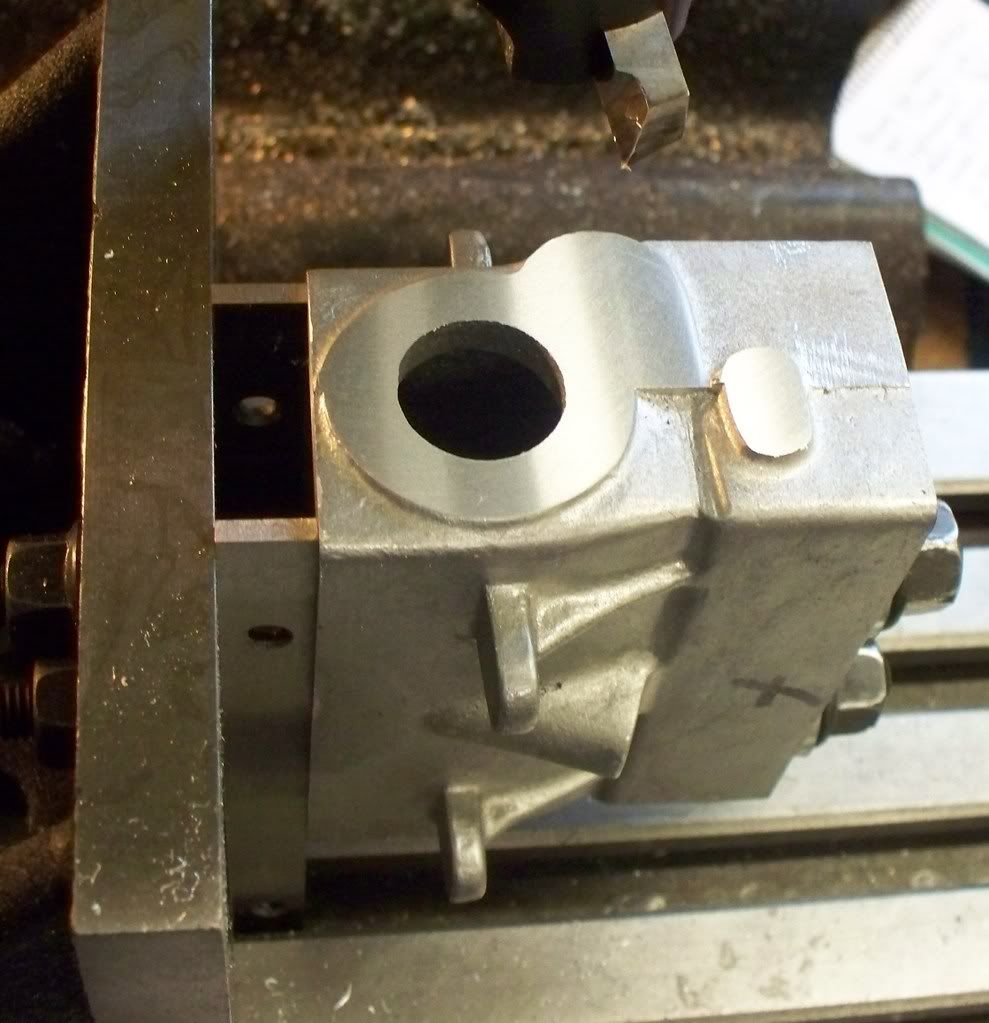

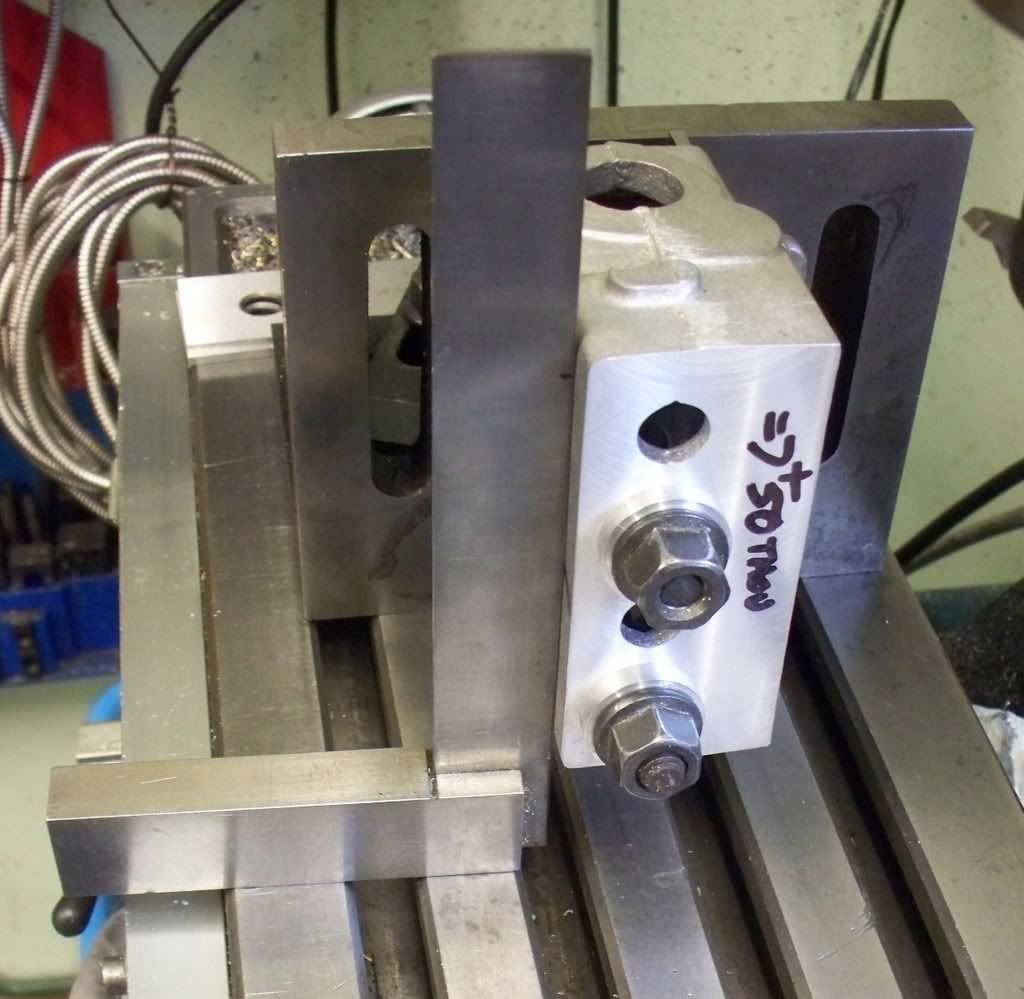

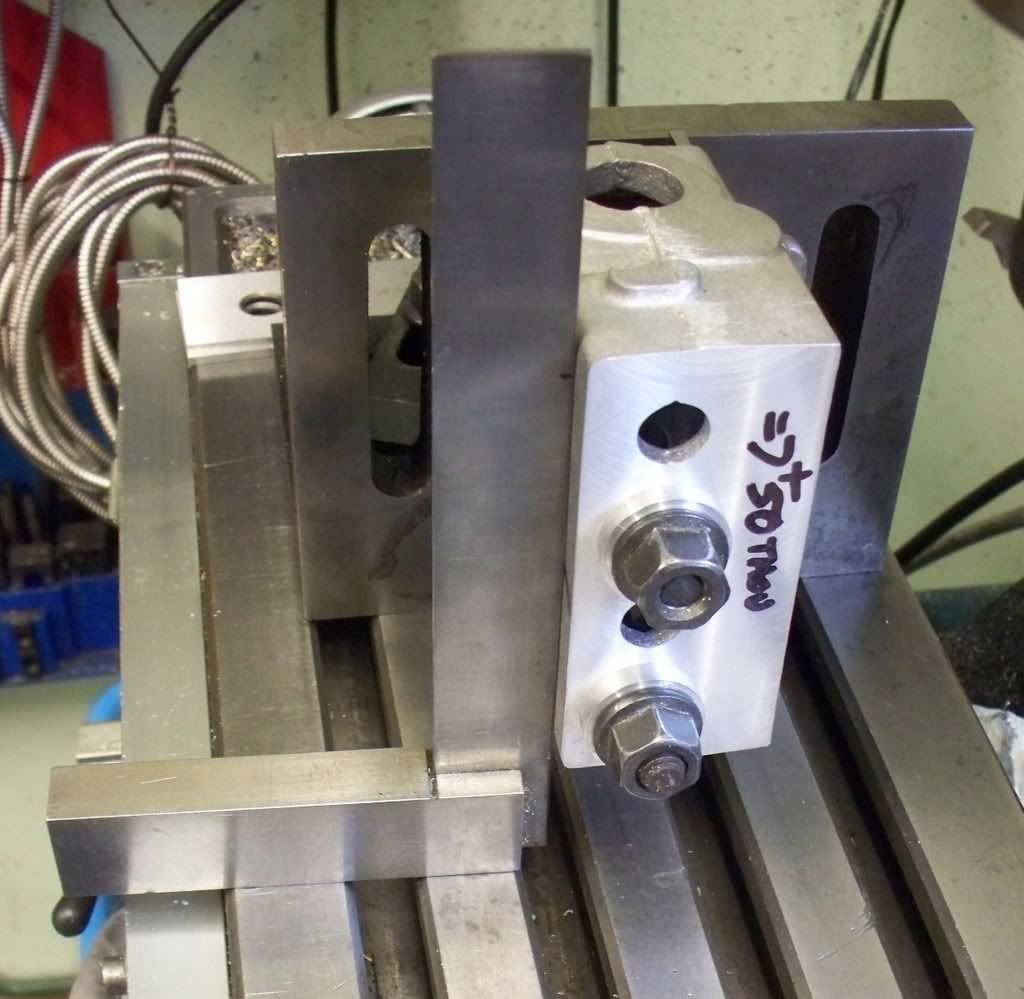

Today I only managed an hour or so, and decided I would clean up the two ends of the casting by mounting it on an angle plate (see photo). I made a couple of aluminium washers to protect the top of the block (although I have another 50 thou or so to take off -easy to make a dig or two). Using parallels to give space The top was soon cut to dimensions. the casting was then reversed and the same actions taken.

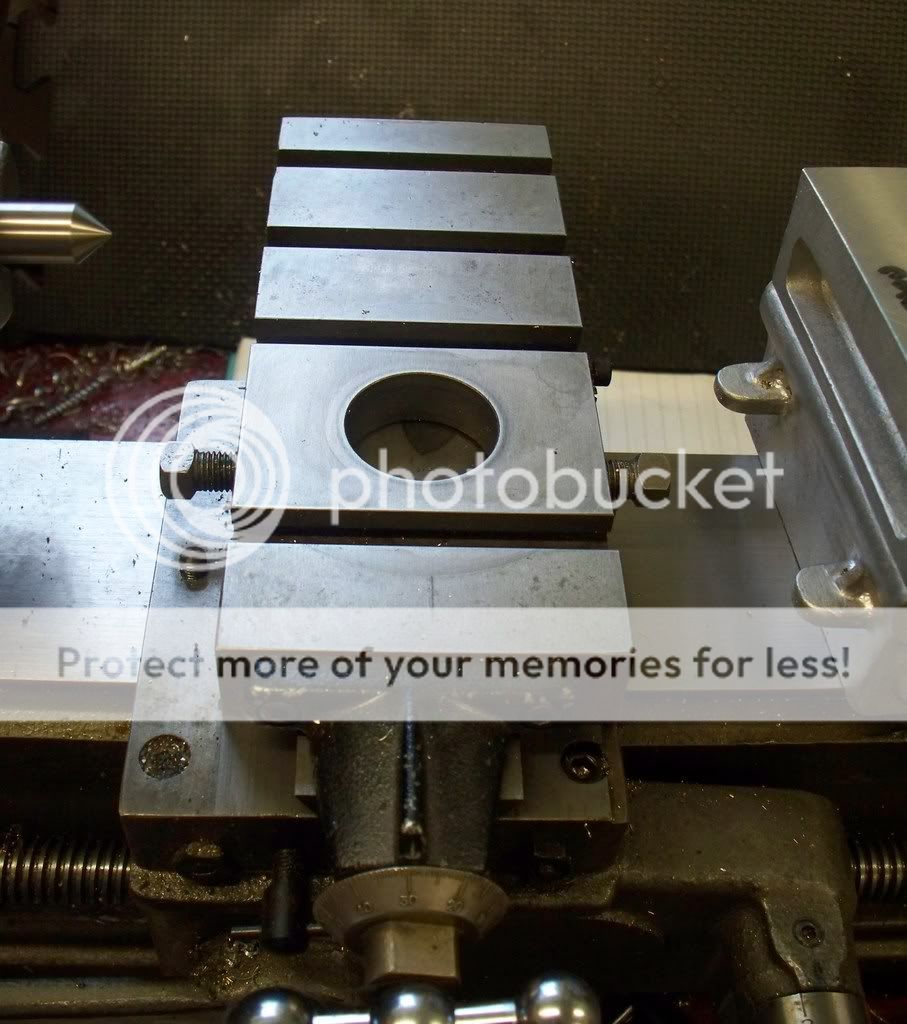

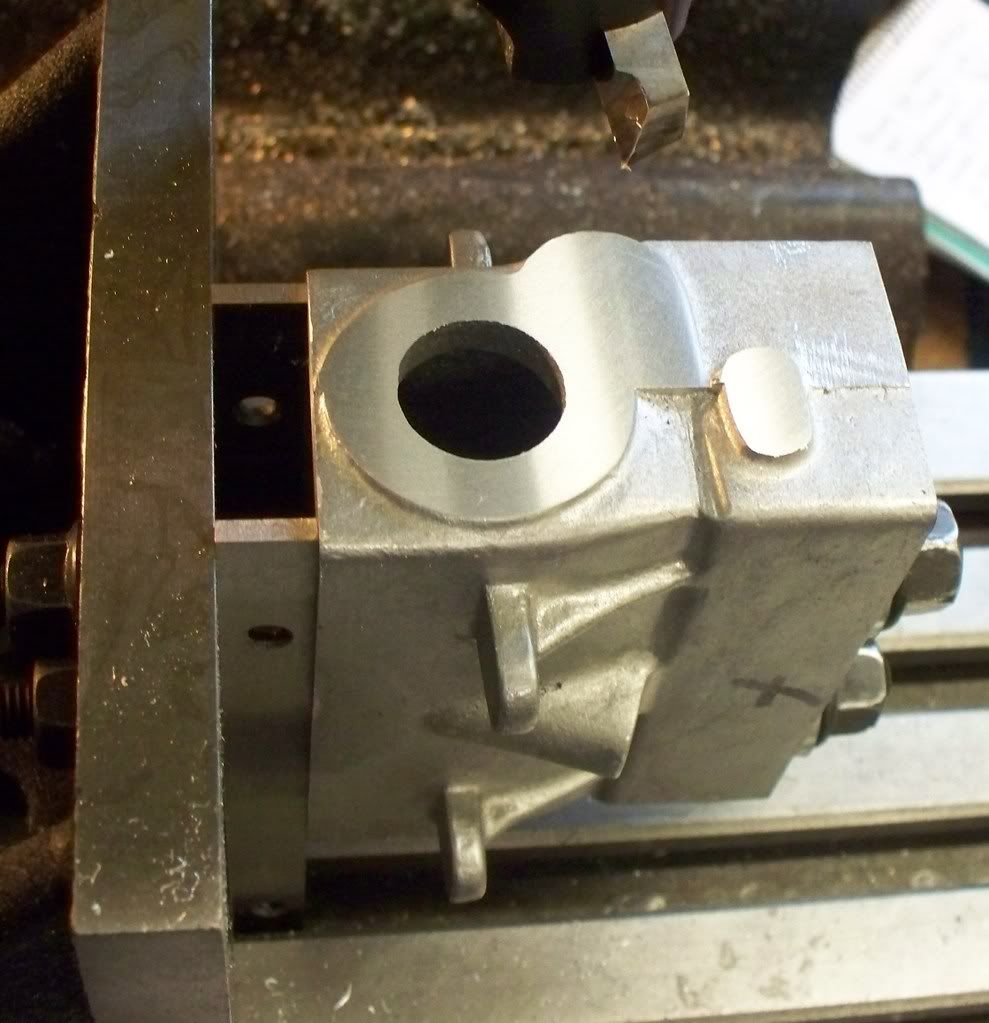

Now come a request for help or guidance. When checking the casting for overall length against the plan it was more than 1/4" too long still. You can see the difference with the unmachined cylinder head lain on the supposedly finishe block (only in length).

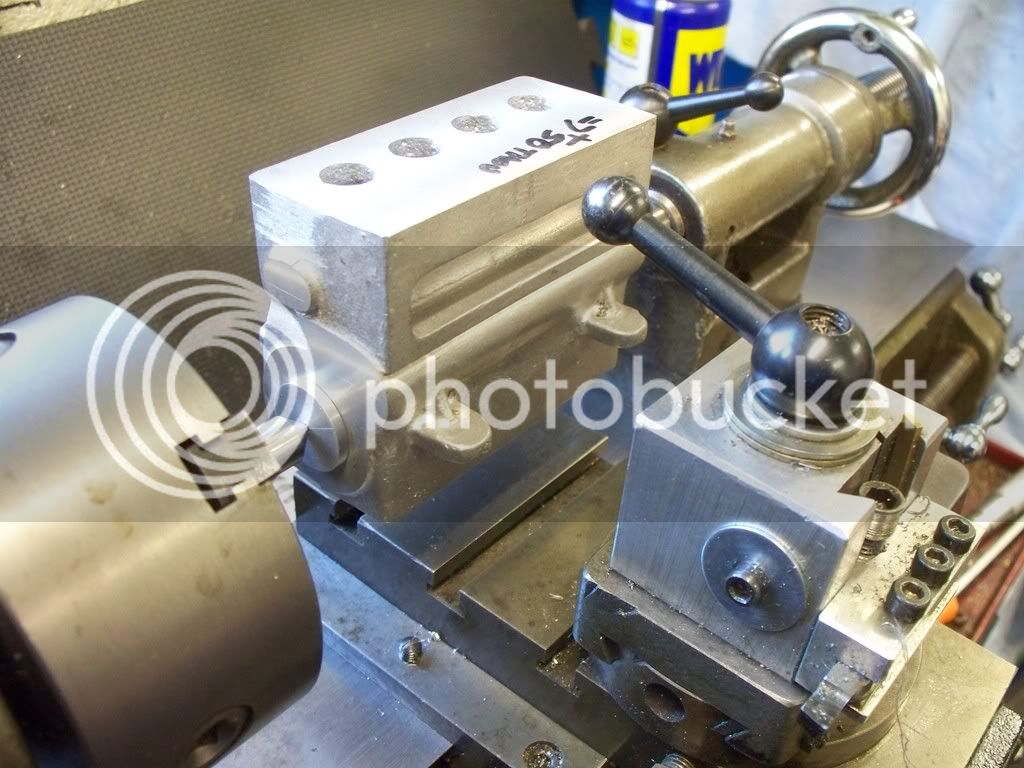

Now the question is, do I machine off one end to get the block to length and loose the shape of the casting end? (If I tooks some off each end I would loose the overall shape on both!) Or do I remove as much as I can whilst still retaining the shape, and then measure the difference between actual block and the plan, then making the extra onto the camshaft and crankshaft etc.

The second option is my favoured but am I letting myself in for more problems. I also have the difficulty of the block being bigger than some of its attacnments in width as well as length. i.e. the sump and the cylinder head (only in length).

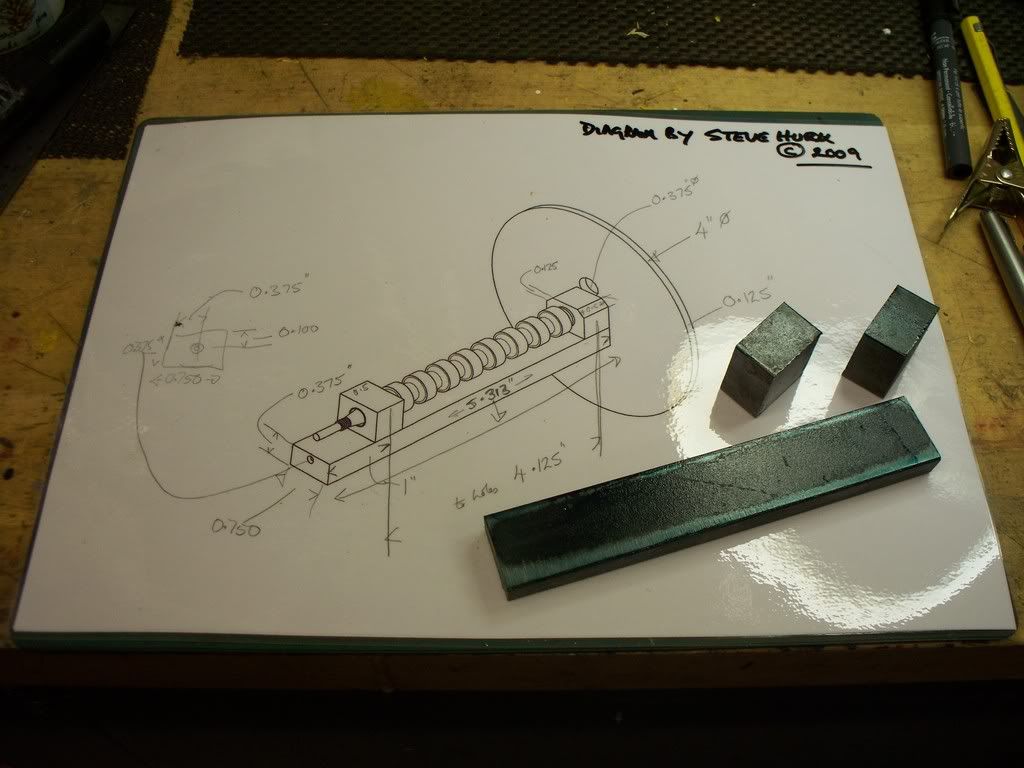

I thought it better to raise the issue here and sleep on it before taking off metal that would be difficult sticking back on with blue tack!

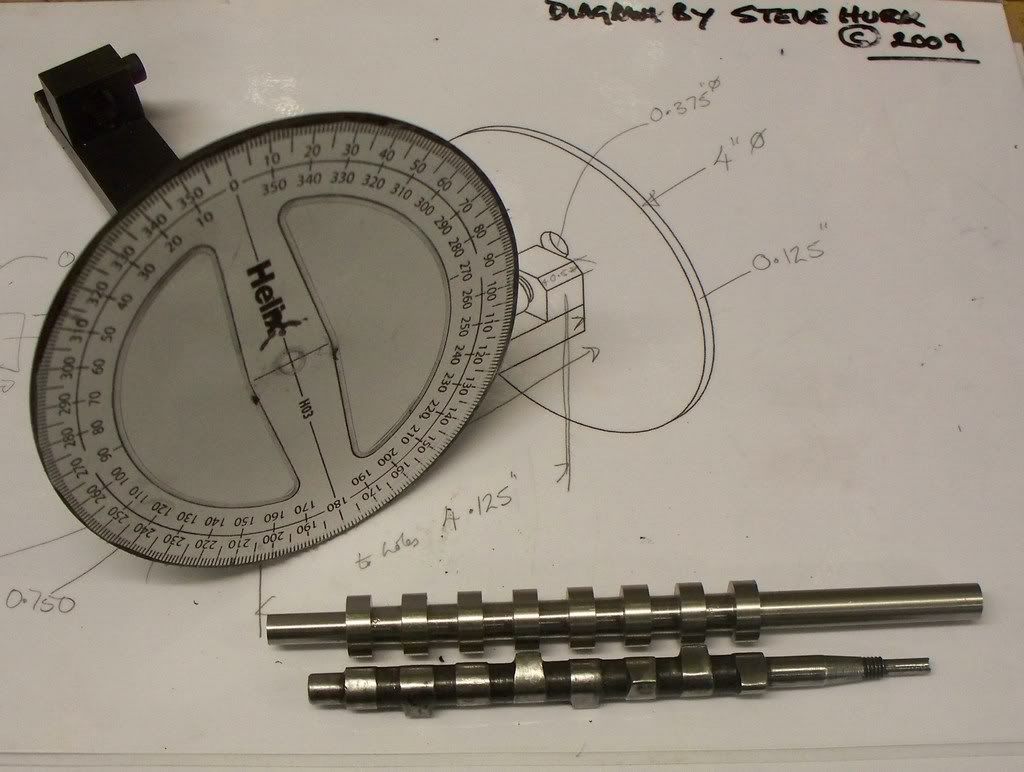

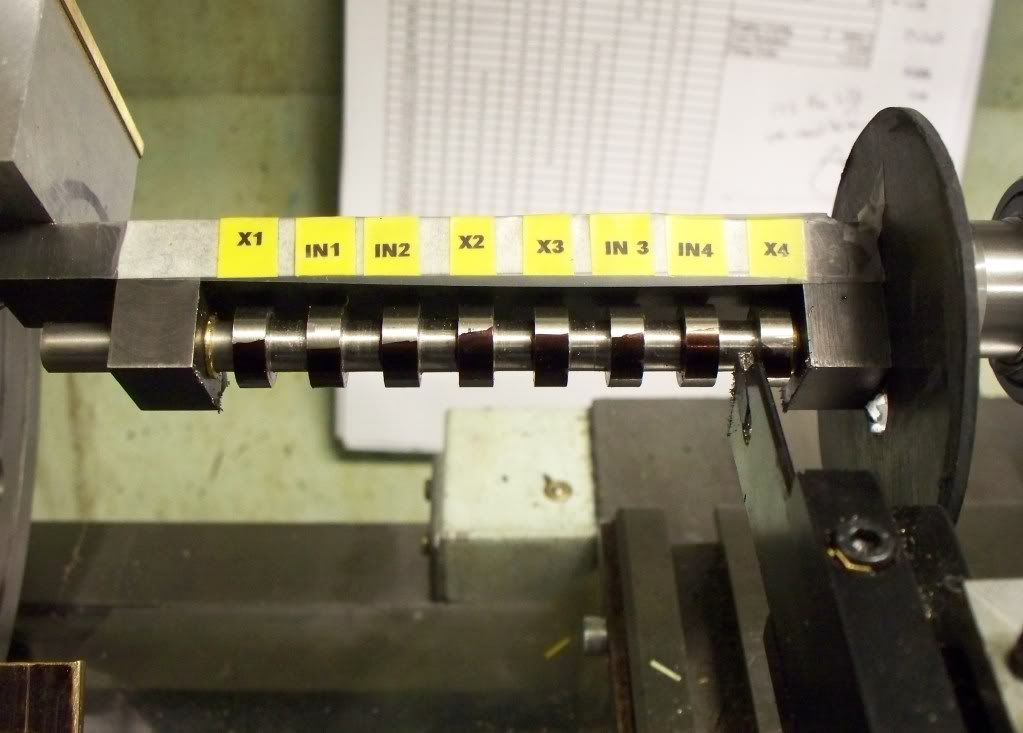

Here are a couple of images.......

and the difference in castings......

and finally................

Today I only managed an hour or so, and decided I would clean up the two ends of the casting by mounting it on an angle plate (see photo). I made a couple of aluminium washers to protect the top of the block (although I have another 50 thou or so to take off -easy to make a dig or two). Using parallels to give space The top was soon cut to dimensions. the casting was then reversed and the same actions taken.

Now come a request for help or guidance. When checking the casting for overall length against the plan it was more than 1/4" too long still. You can see the difference with the unmachined cylinder head lain on the supposedly finishe block (only in length).

Now the question is, do I machine off one end to get the block to length and loose the shape of the casting end? (If I tooks some off each end I would loose the overall shape on both!) Or do I remove as much as I can whilst still retaining the shape, and then measure the difference between actual block and the plan, then making the extra onto the camshaft and crankshaft etc.

The second option is my favoured but am I letting myself in for more problems. I also have the difficulty of the block being bigger than some of its attacnments in width as well as length. i.e. the sump and the cylinder head (only in length).

I thought it better to raise the issue here and sleep on it before taking off metal that would be difficult sticking back on with blue tack!

Here are a couple of images.......

and the difference in castings......

and finally................