- Joined

- Jul 29, 2008

- Messages

- 560

- Reaction score

- 62

bernd,

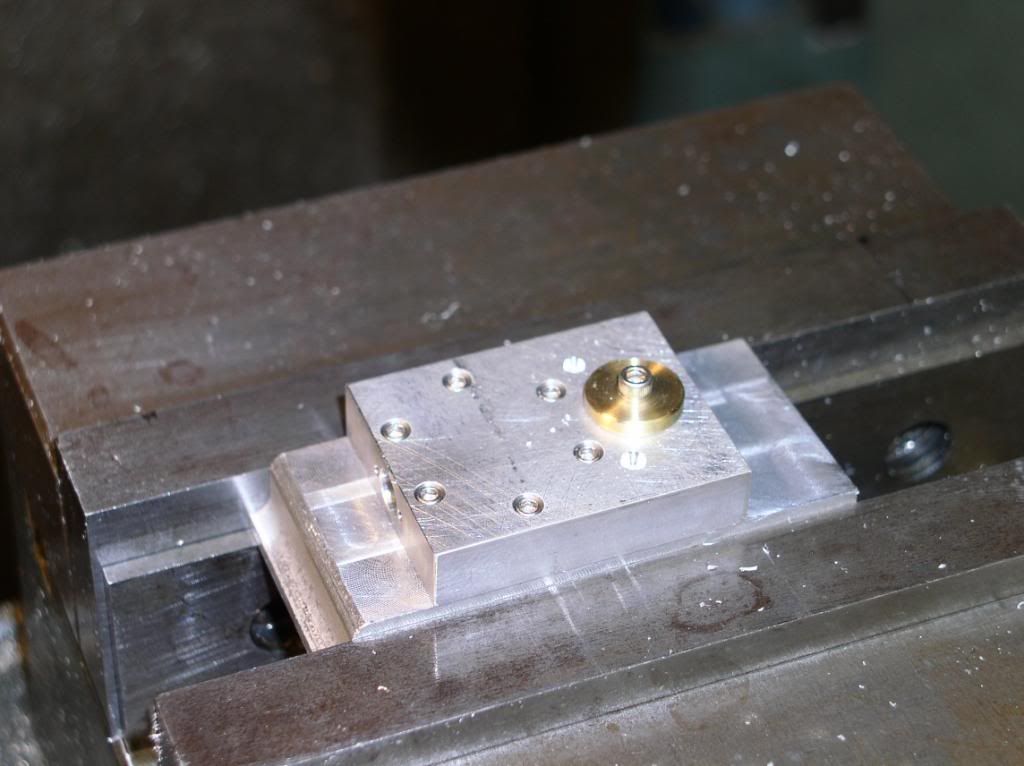

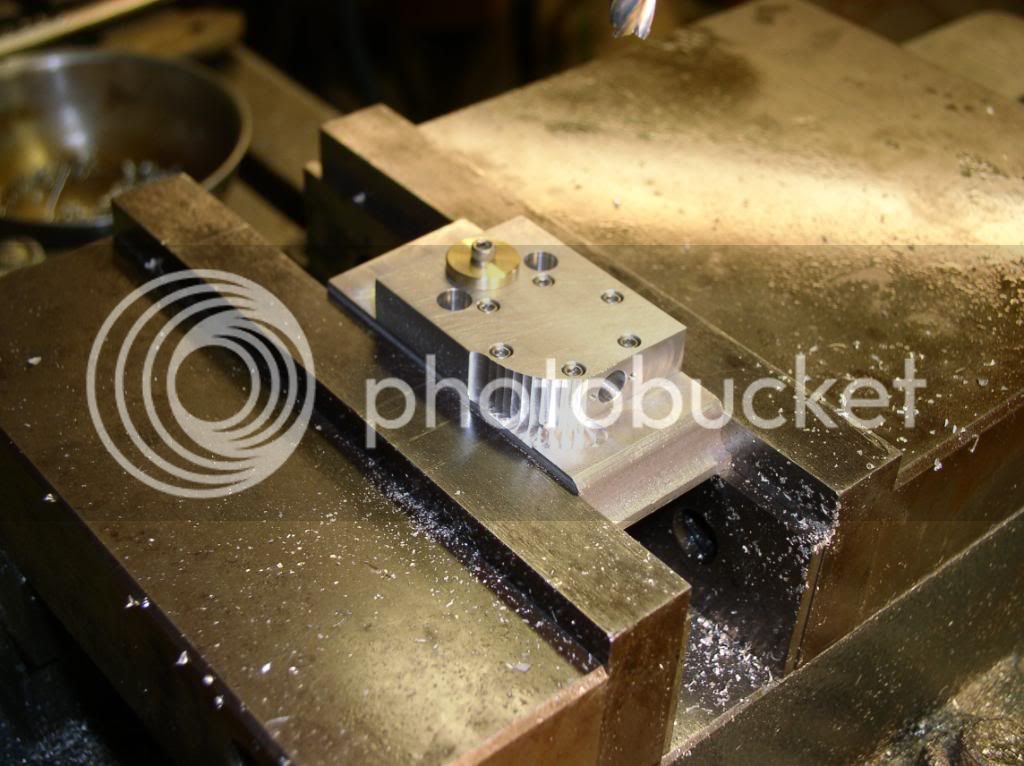

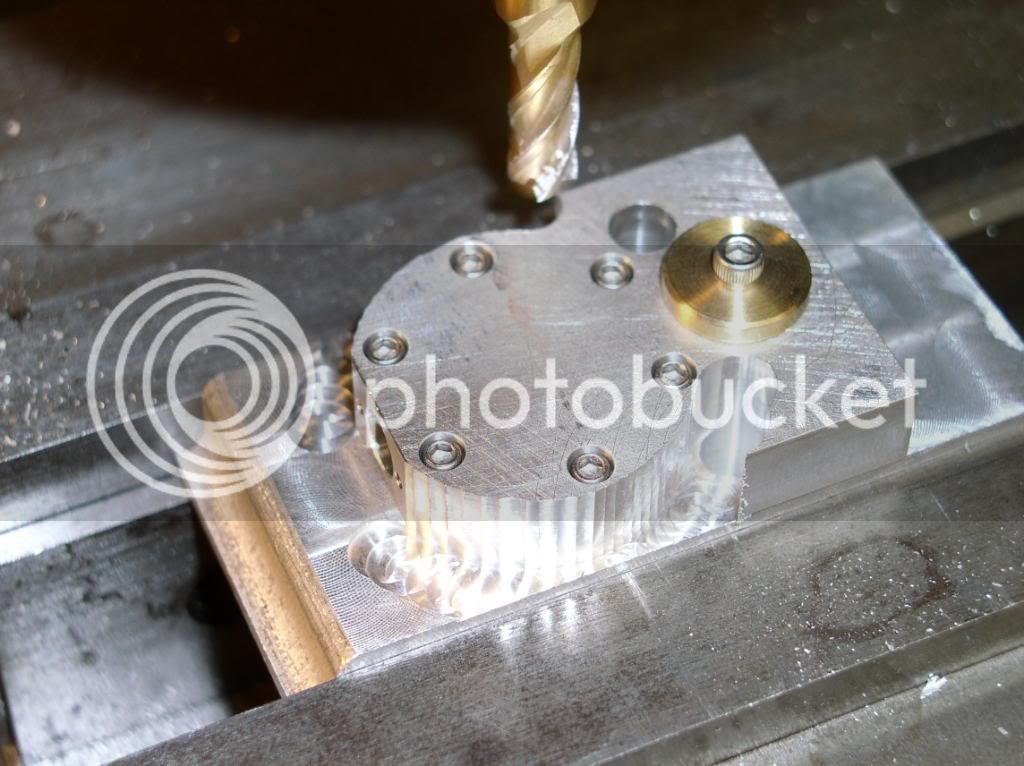

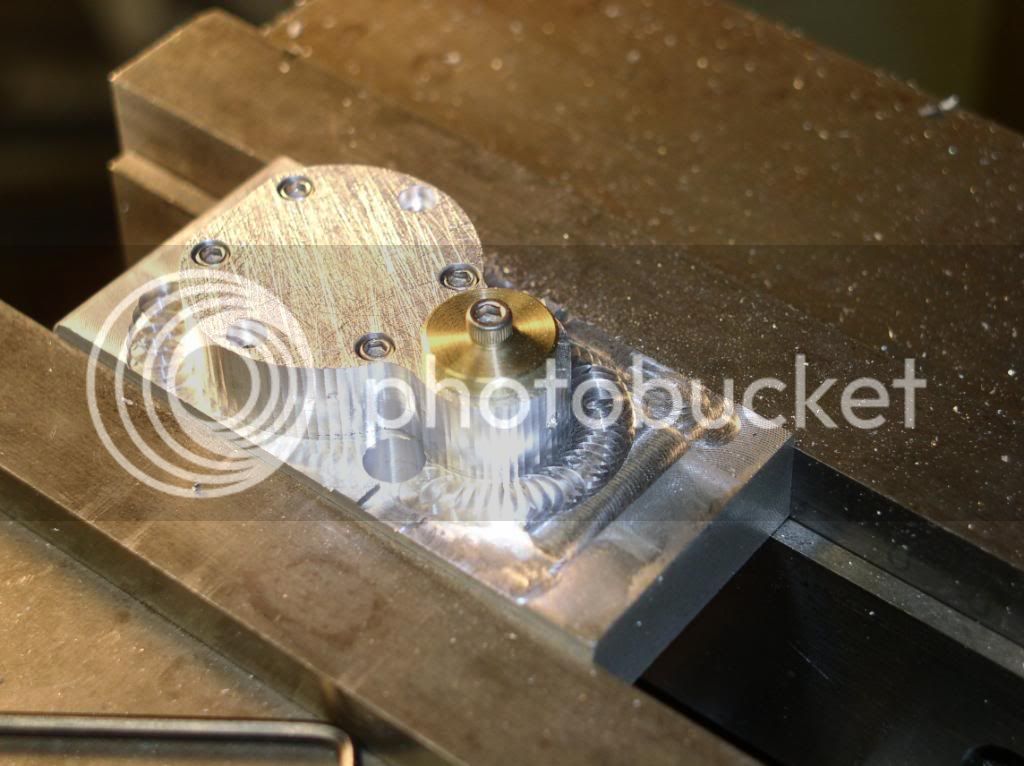

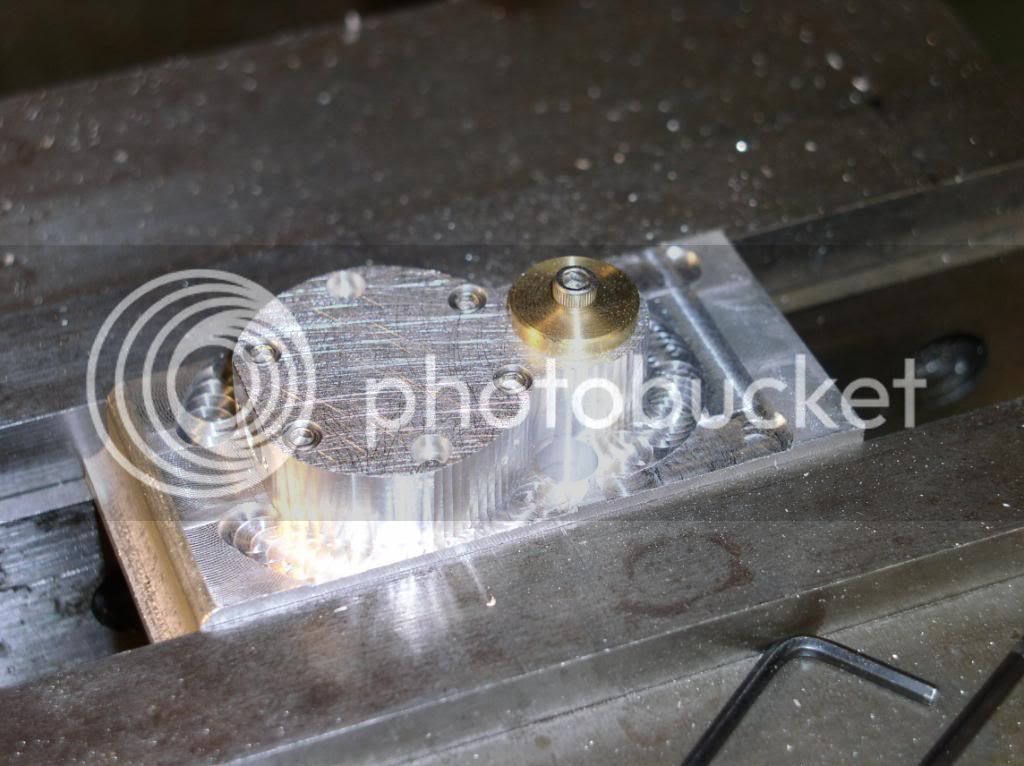

I cheated. the part was placed on parallels upon setup. The holes would have hit them when drilled. I knock them out very gently brfore I drilled. They will not move due to most of the part being in the vice and I use little pressure when drilling. This may not be the best way to do it but it has worked on several engines I have worked on and I have never had a problem.

Good Eye you caught me ;D ;D

I cheated. the part was placed on parallels upon setup. The holes would have hit them when drilled. I knock them out very gently brfore I drilled. They will not move due to most of the part being in the vice and I use little pressure when drilling. This may not be the best way to do it but it has worked on several engines I have worked on and I have never had a problem.

Good Eye you caught me ;D ;D