- Joined

- Jul 29, 2008

- Messages

- 560

- Reaction score

- 62

This is my second attempt to do this post. In my first attempt I got excited when the Eagles beat the Vikings. I forgot the hit the post tab. :wall: Well here it goes again.

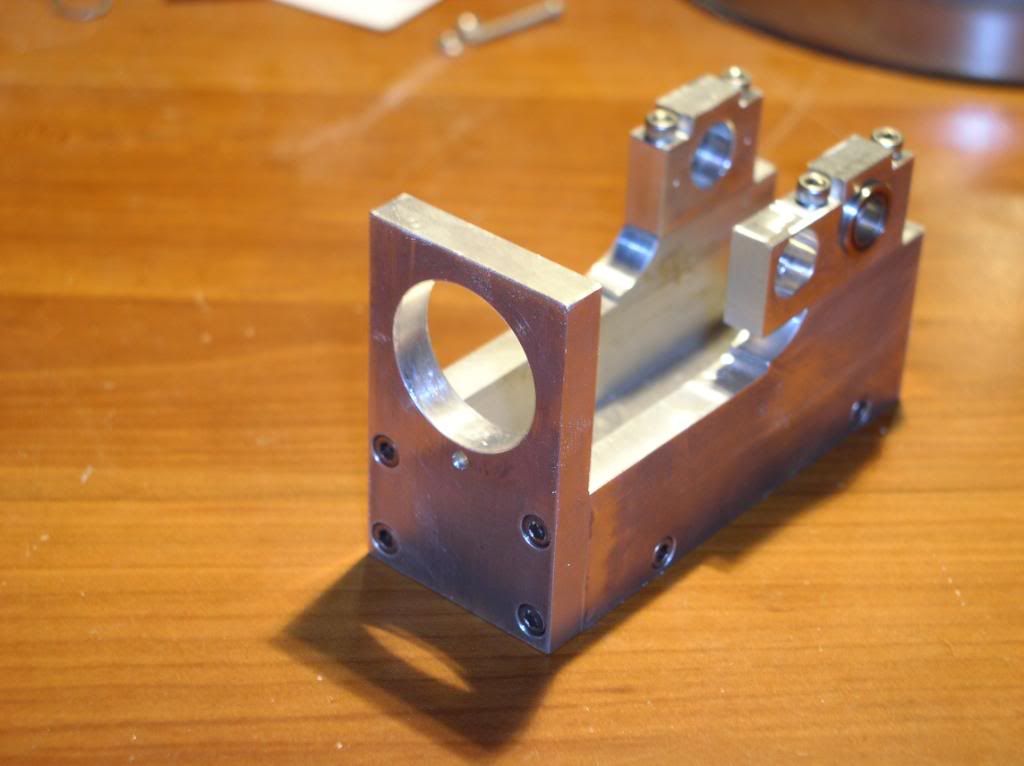

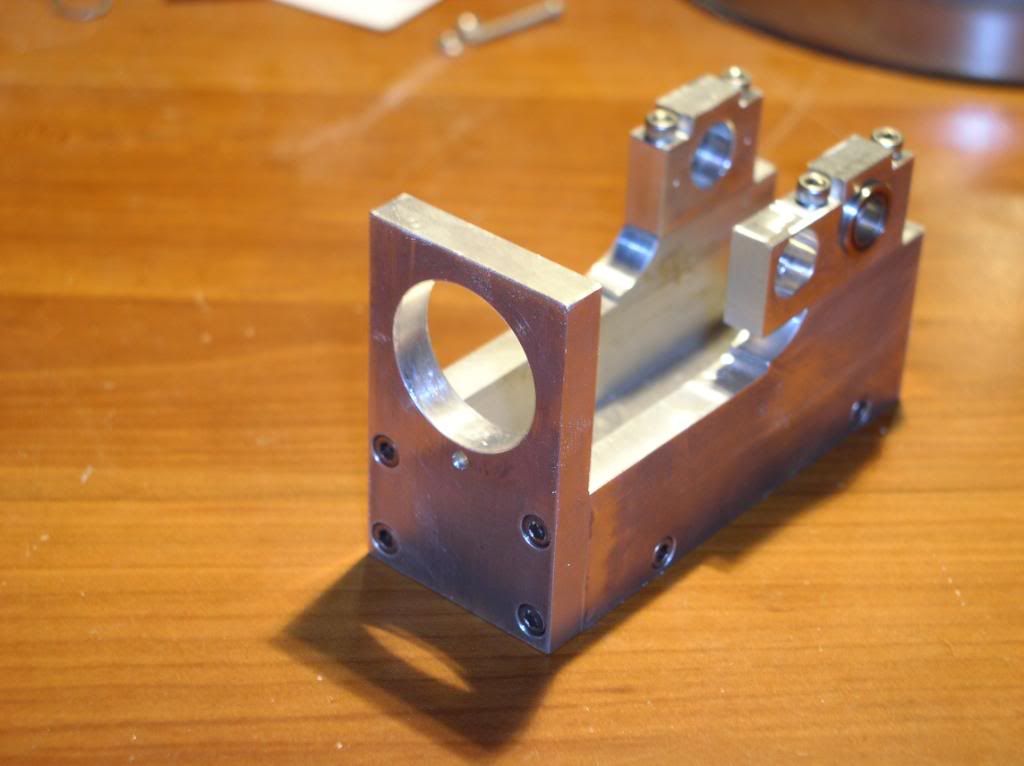

I started Chucks Single two weeks ago. I got some parts done and wanted to share them with the members.

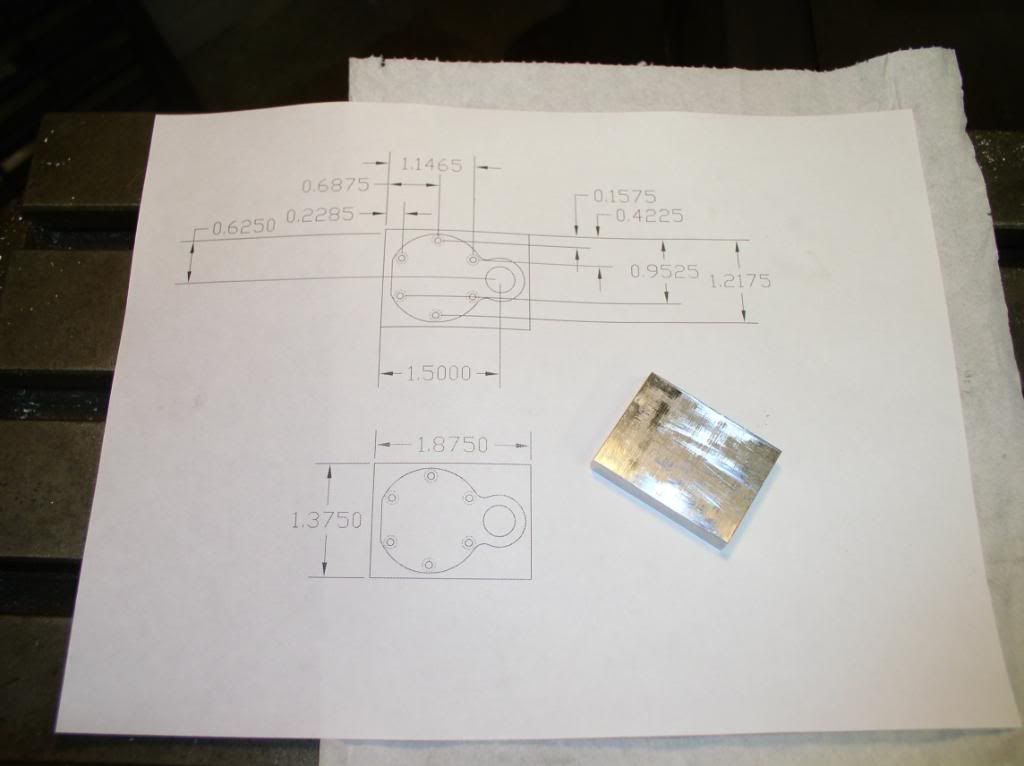

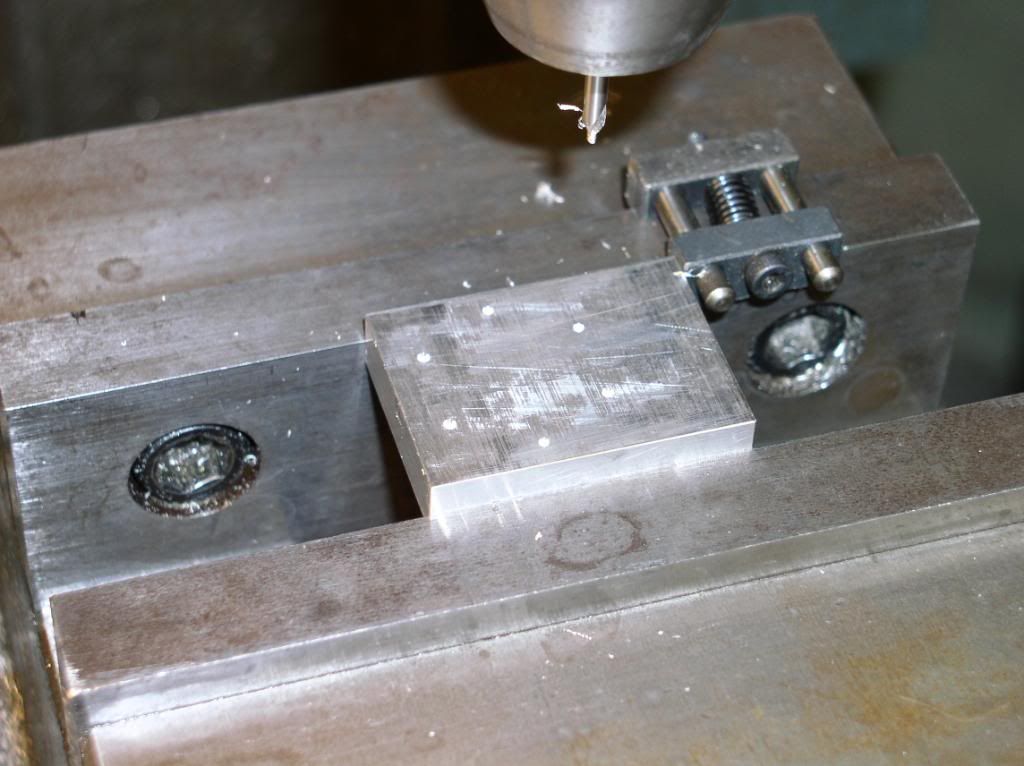

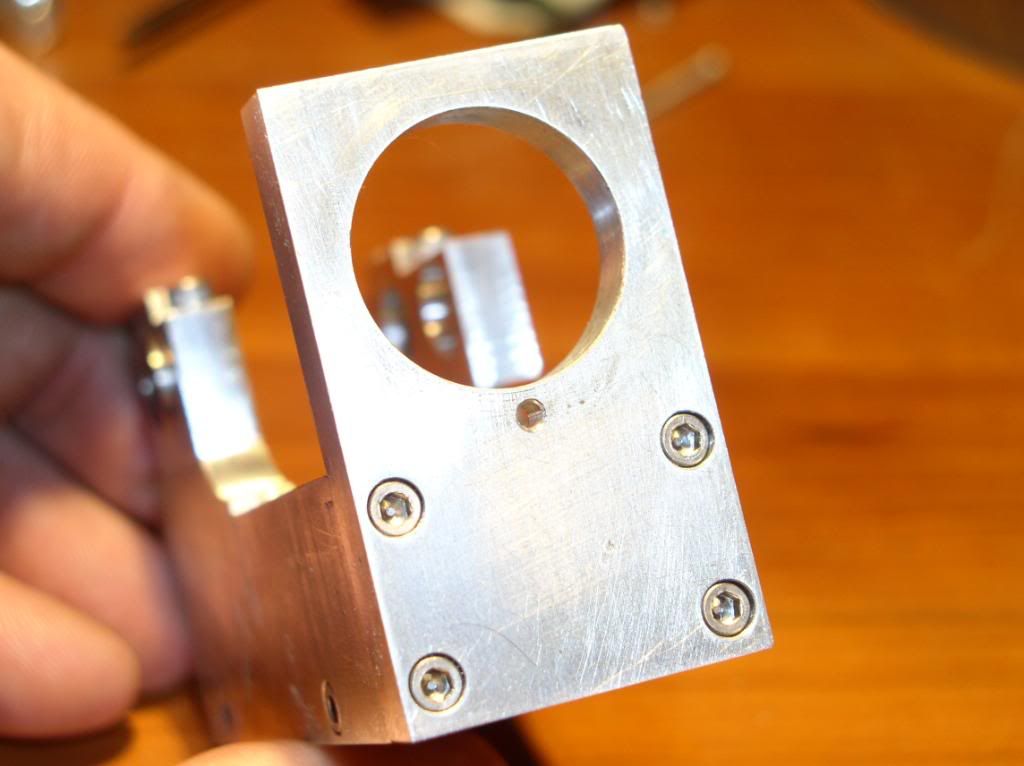

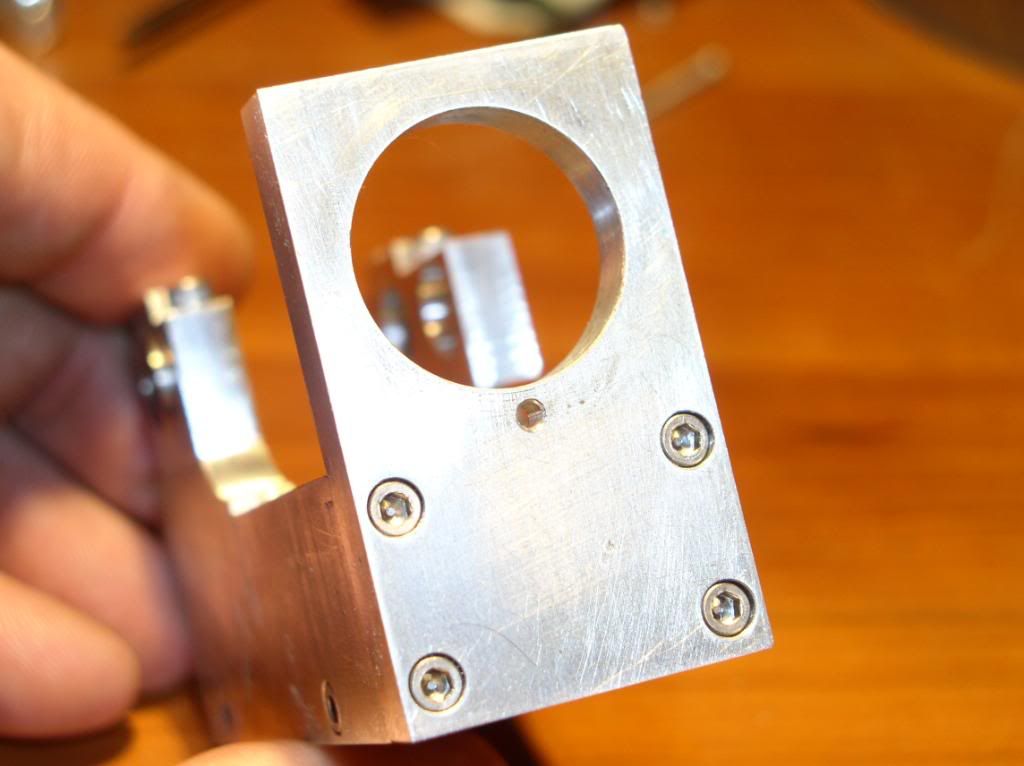

I started with the base which I made out of 1/4 inch aluminum plate. This is a strait forward part to make.

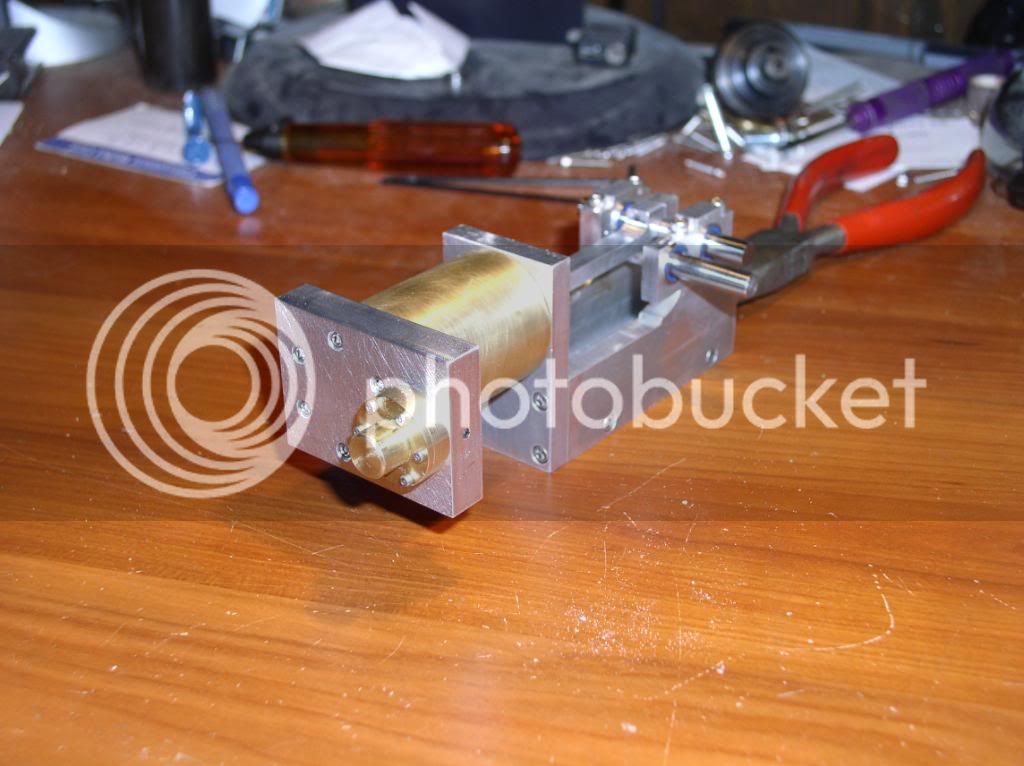

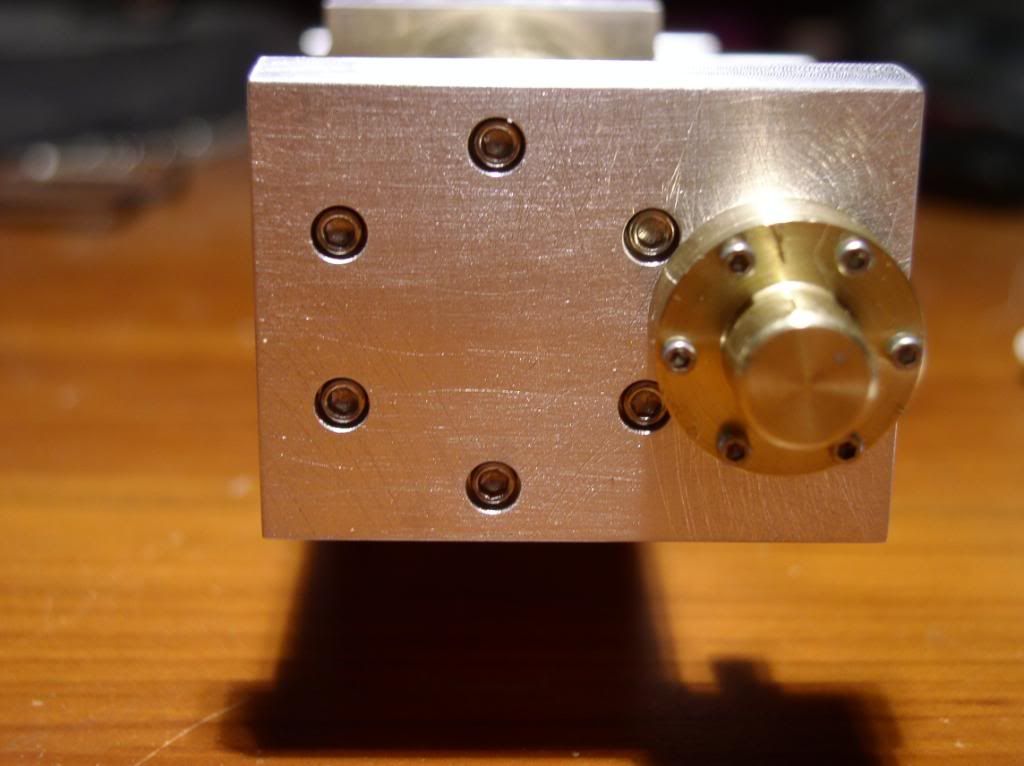

The second part I made was the Cylinder which i made in two parts. I made a liner which started out as 1 inch X .760 ID d.o.m. tube from wicks aircraft supply. The liner was truned to .900 OD. The outer sleve is made from brass which should give a good bling after polish. The two were put together with epoxy

I made the valve parts next both were made with brass as well. The two are held together with 0-80 socket head cap screws. I will make the valve when I get the valve seat cutter made.

I made the rod and piston today. They are both made out of aluminum. I made the piston with a .001 clearance.

This is a little bugger to make. I wish I would have placed a coin to show its size. I made mine like bretk did. It will have an ajustable rod which will screw onto the 2-56 rod with the locknut.

I made my cylinder with a slip fit to the front base so I could easly remove it latter if needed. The two are held together with a 2-56 bolt at 6 o'clock.

This is all the parts that are made to date. Some need futher work done to them

I started Chucks Single two weeks ago. I got some parts done and wanted to share them with the members.

I started with the base which I made out of 1/4 inch aluminum plate. This is a strait forward part to make.

The second part I made was the Cylinder which i made in two parts. I made a liner which started out as 1 inch X .760 ID d.o.m. tube from wicks aircraft supply. The liner was truned to .900 OD. The outer sleve is made from brass which should give a good bling after polish. The two were put together with epoxy

I made the valve parts next both were made with brass as well. The two are held together with 0-80 socket head cap screws. I will make the valve when I get the valve seat cutter made.

I made the rod and piston today. They are both made out of aluminum. I made the piston with a .001 clearance.

This is a little bugger to make. I wish I would have placed a coin to show its size. I made mine like bretk did. It will have an ajustable rod which will screw onto the 2-56 rod with the locknut.

I made my cylinder with a slip fit to the front base so I could easly remove it latter if needed. The two are held together with a 2-56 bolt at 6 o'clock.

This is all the parts that are made to date. Some need futher work done to them