- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

I learned a new "trick" yesterday (they always seem obvious afterwards).

A couple of times I have had workpieces chucked in a hex collet block where I needed to remove the piece and then replace it later. The first time I re-oriented the piece by eyeball and was a bit off, to my detriment.

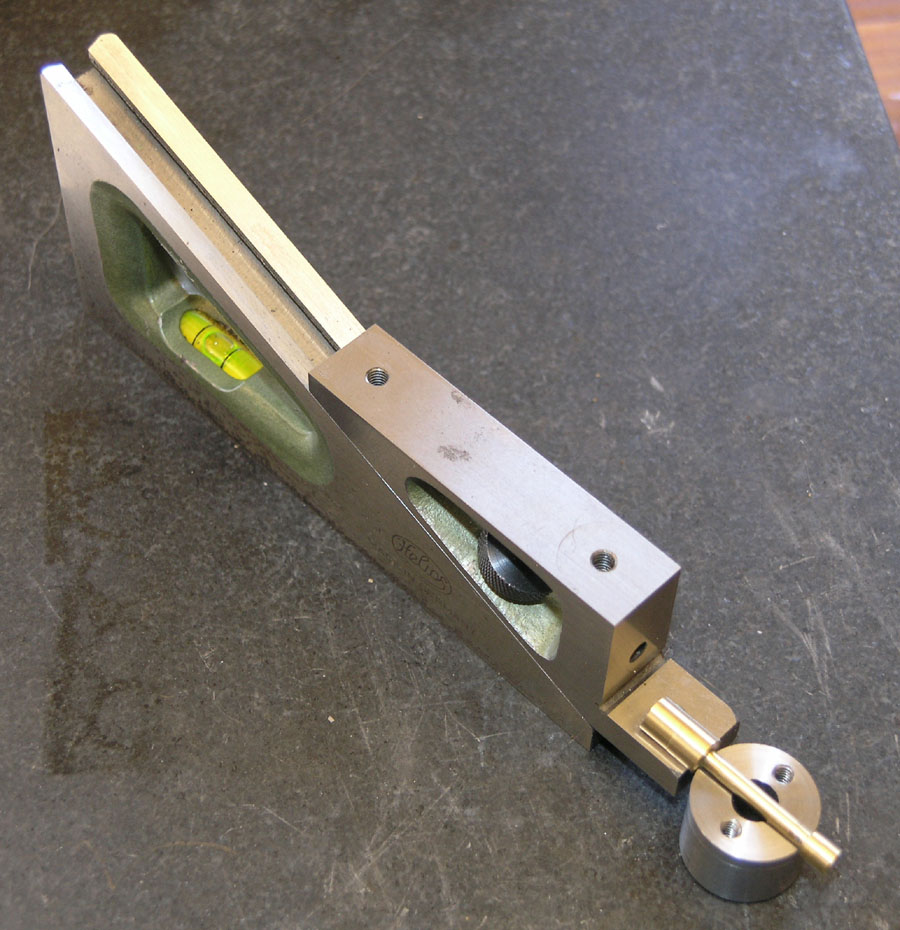

One way to replace a piece in a hex block where a previously milled face needs to be coplanar with a side of the block is to place the block on a flat surface and use a height gauge to position the work. Then you can tighten the lock nut. With a square block a machinist'd square would work equally well.

If the alignment is against a point of the hex block then the block can be clamped in a small vise and set on the surface plate before using the height gauge.

A couple of times I have had workpieces chucked in a hex collet block where I needed to remove the piece and then replace it later. The first time I re-oriented the piece by eyeball and was a bit off, to my detriment.

One way to replace a piece in a hex block where a previously milled face needs to be coplanar with a side of the block is to place the block on a flat surface and use a height gauge to position the work. Then you can tighten the lock nut. With a square block a machinist'd square would work equally well.

If the alignment is against a point of the hex block then the block can be clamped in a small vise and set on the surface plate before using the height gauge.