Hello,

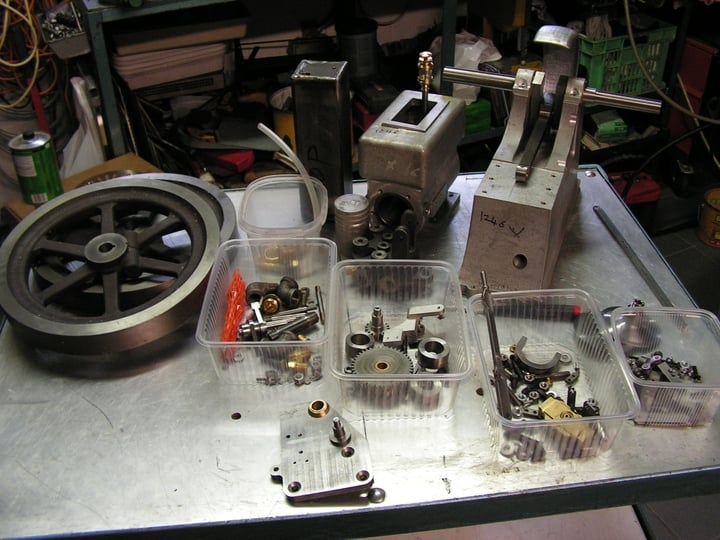

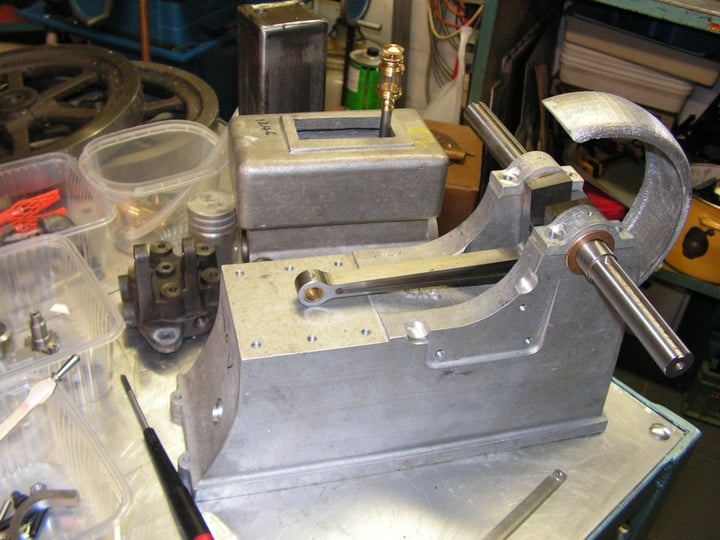

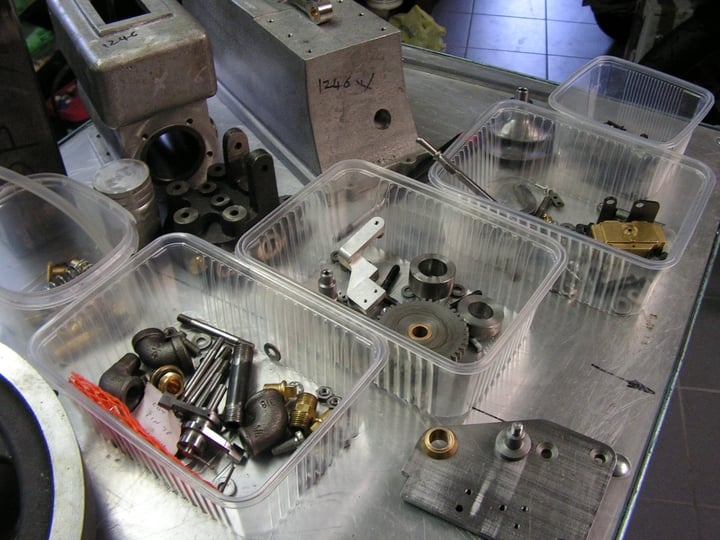

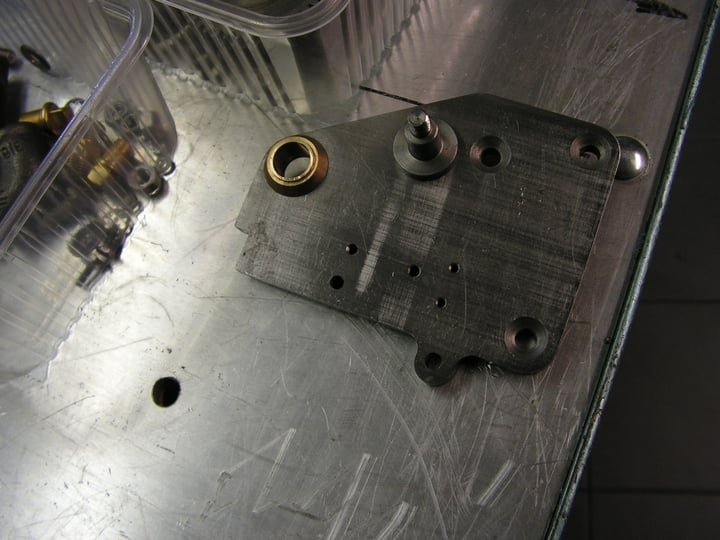

I am not such a good machinist , so I order a premachined kit by the "engineers emporium" from the ECONOMY hit & miss engine. The kit arrived in a very heavy box. After unpacking I see beautifull machined parts. All those parts where covered with something that stinks like heavy fuell. So I cleaned everything with aceton.

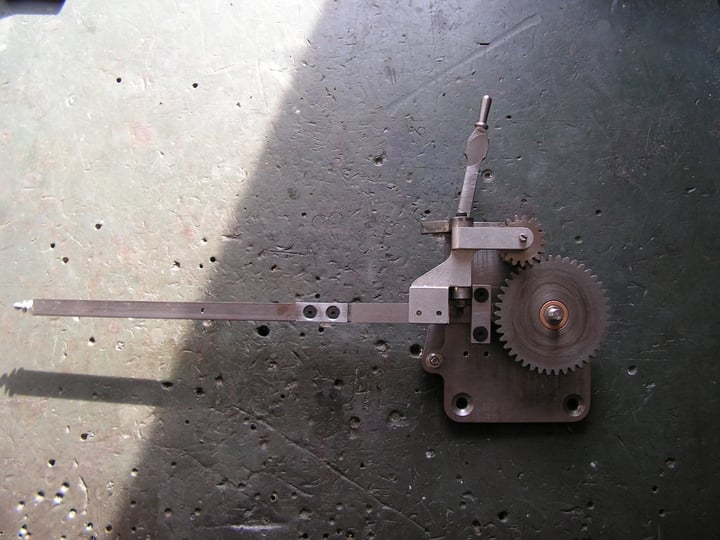

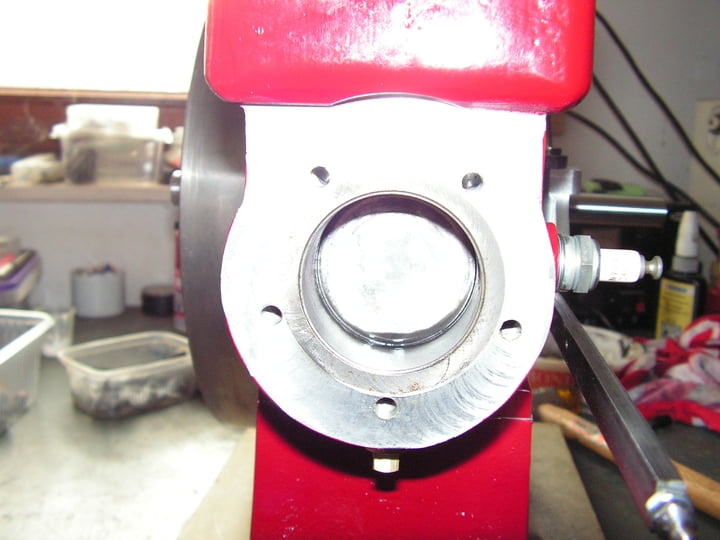

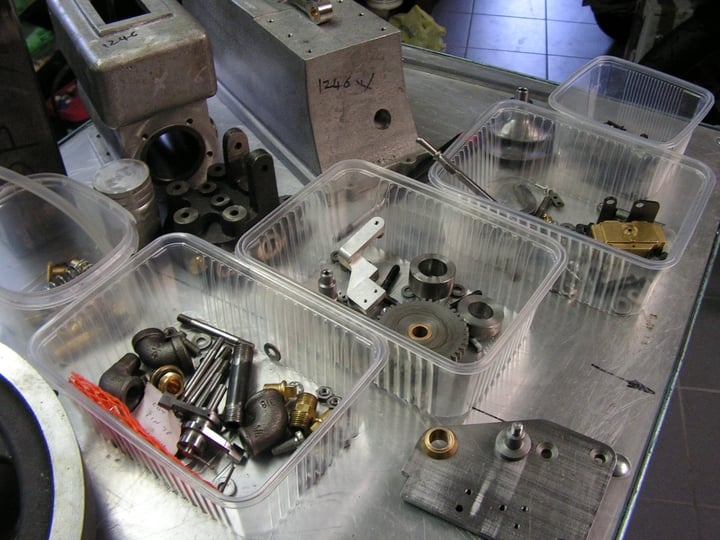

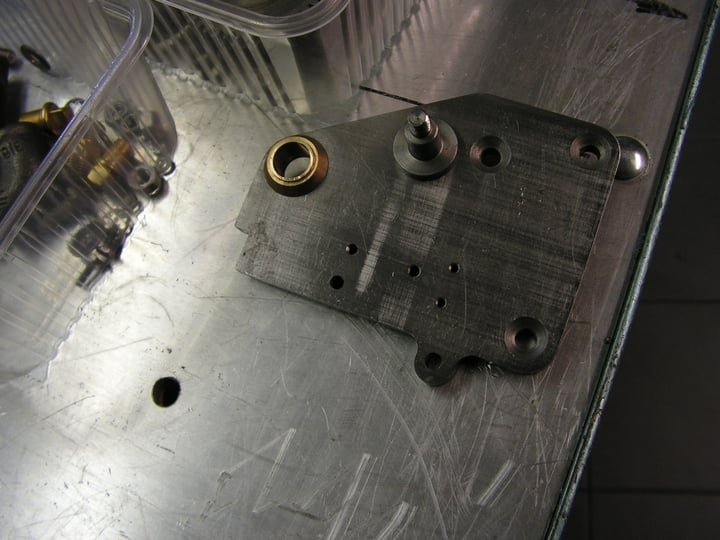

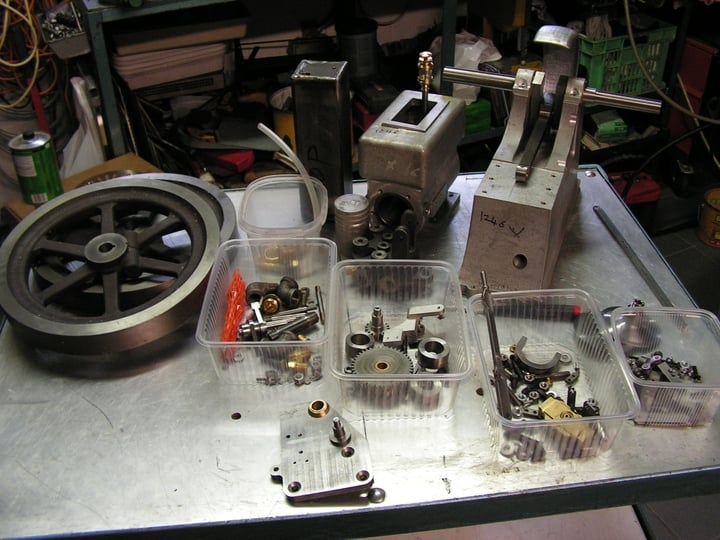

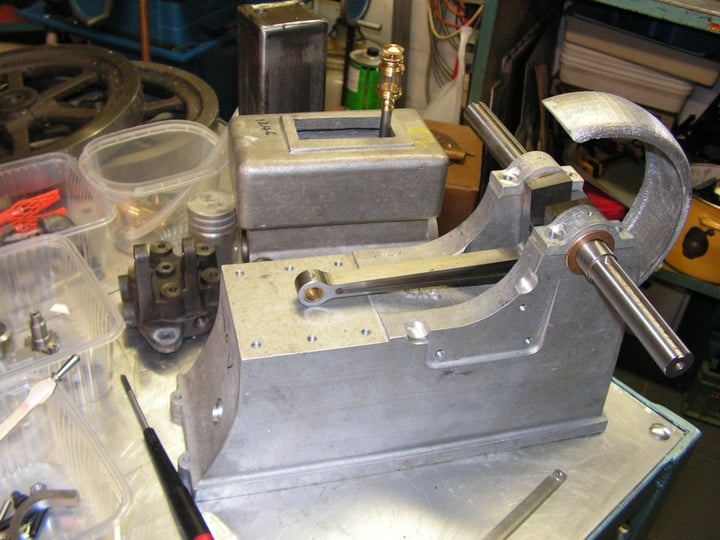

Here some pictures from the kit:

The pieces that have to be painted , I give it to a professionel painter. With the operation in my shoulder , I can not move my right arm , so that is why I do not the paint this time.

I can grind already the valves & I have coarse and fine paste here. But a question......How long I have to grind & how far I need to go. Also , how can I test that they are not leaking.

By my Little Wonder engine , the exhaust valve leaks a little bit.

Barry

I am not such a good machinist , so I order a premachined kit by the "engineers emporium" from the ECONOMY hit & miss engine. The kit arrived in a very heavy box. After unpacking I see beautifull machined parts. All those parts where covered with something that stinks like heavy fuell. So I cleaned everything with aceton.

Here some pictures from the kit:

The pieces that have to be painted , I give it to a professionel painter. With the operation in my shoulder , I can not move my right arm , so that is why I do not the paint this time.

I can grind already the valves & I have coarse and fine paste here. But a question......How long I have to grind & how far I need to go. Also , how can I test that they are not leaking.

By my Little Wonder engine , the exhaust valve leaks a little bit.

Barry