Thanks Jack! I appreciate your comments, especially since we are building twins.

I've never been able to find any kind of 2-56 screws longer than 1/2" where I live. It's a small town, (3500), and some little bits are not to be had, (but if you want something for a John Deere, you're in luck!). I make most any fastener I need that is smaller than 4-40, out of necessity. I kind of like making my own cap screw nuts in the smaller sizes, simply because most store bought items look oversized across the flats.

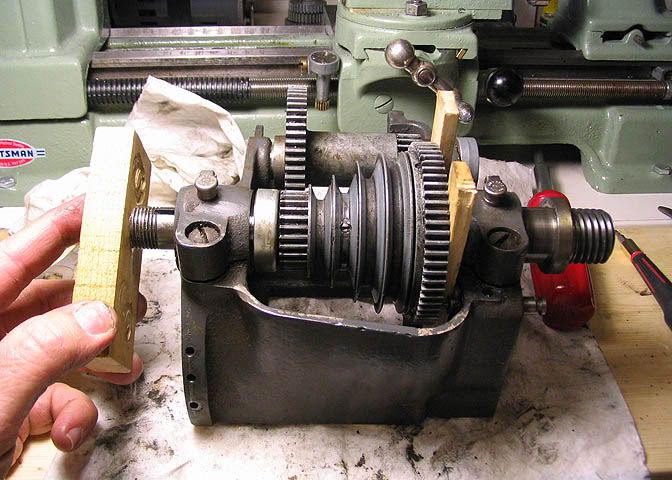

Got a little done today. I'm not a fast builder. Been occupied with the new/old lathe, and plowing this

morning's eight inches of snow off my 1/2 mile long driveway. Excuses, excuses.

This will be the big end of the connecting rod. Remember that piece of 3/4" square that was made

from a piece of round stock earlier? This is some more of it, here. It will be .625" square when I

get done with it. Hack-sawed a little piece of it off and in the picture it's being cleaned up with the fly

cutter.

Once the piece is brought to its proper thickness, it's put on end to take one side down to finished

size. It needs to be square, and in this shot I'm checking it with a small machinists square and a

flashlight. The flashlight helps you see the edge of the piece against the square, and by the light

that comes through, you can see if it's square or not.

I need to drill the cross holes in the piece next. Above, a cigarette paper is being used to find the edge

of the work piece. I've known a number of ol' machinists that use this method, even though an edge

finder might be handy, and I use it often myself.

For those who may not be familiar with it, you put your piece of paper against the work piece and run

your tool up near it, then crank the slide over slowly while pulling the paper back until you feel the tool

start to barely pinch the paper. You do this with the machine turned off, by the way. When the paper

starts to get stuck between the tool and work piece, you're there, within the thickness of the paper.

These particular papers, (Top brand) dial at .001" thick. If you buy a different type for rolling up your la

bambas, they might be thicker..

Some machinists do this trick with the machine running, and when the tool snatches the paper from

between their fingers, they know it's good. For my part, I'm pretty attached to my fingers, and would

rather do it with the machine turned off.

The holes are drilled through for a 2-56 tap.

The blue line is an index mark so I keep the pieces matched up after it is cut in half.

Then the piece is cut in half with a hack saw. I would have used a slitting saw, but I seem to have

misplaced the arbor that fits my milling machine. At this point, the piece is to the proper width, but

was left long to allow for the saw cut.

After the two pieces are cleaned up from the hack saw job, and brought to the correct width on the mill

at the same time, the holes in one piece are tapped 2-56. Tapping small holes in brass is almost fun.

There's so little chance for trauma or drama, like when using small taps in hard metal.

The bottom half is on the right, and it has the tapped holes. The top part, on the left, has had its two

holes drilled out to #43 clearance holes for the two little cap screws.

After putting the two pieces back together using the cap screws, the piece was center drilled at the

location of centerline for the bore for the crank pin. At that point, I realized I didn't have a 5/16 reamer

to finish the job in the mill, so while it was still in the mill vise I drilled a small hole clear through. Then to

the lathe I go.

The piece was mounted using a piece of tool steel between it and the face of the chuck to keep it

square, then the tool steel was removed. Note the pieces of paper wrapped around the brass piece. I

don't want marks in these soft brass bits. I centered it by eye close as I could, then dialed it in with the

old Gem held in the tool post. I like this type of DTI, and prefer them to my other DTI's. They're pretty

darn reliable, the point is easy to reposition, and though they only operate in one direction at a time,

you can switch directions with a flick of the lever on the (other) side of the body.

Then the piece is bored for .312" plus a smidge, for a close running fit on the crank pin.

A "smidge", by the way, is different for different sizes of running fits. Machinery Handbook has a section

on them, I believe.

The last step I'll show is cutting the relief on the sides. Simple turning job. I used a 5/16 piece of drill

bit as an arbor, with a couple of snips of paper squeezed between the work piece and the arbor to

make it tight. If the pieces of paper aren't used, the piece will simply spin on the arbor, since it is the

same size as the crank pin, and is a running fit in the work piece. An oil cup has to be made for this, but

I won't show it here since I already showed the same things being made for the main bearings earlier in

this thread.

That's it for today. I know it's a lot of pictures for such a little thing, but I figured a few folks might

want to see it.

'Til the next part, thanks for having a look.

Dean