Rob, Dennis, Vernon, Dean & Stew - thank you very much for checking in

Rob, thanks very much mate - the finish in the cylinders is from the same boring bar I made that originally gave you a crick in the neck ;D - and thank you for the comment on my band saw mod, I'm very glad I made it; with material being scarce here in Windhoek, I need to use every bit I can ;D

Dennis, Vern & Ron - thanks for your support guys; your request for the rolling stock build is noted and on the tuit list

- but that will remain a future project for now. I just want

need the loco to satisfy a little boy in myself that's been dreaming of it for 30-odd years ;D

Dean, thank you; I wish I was further along though, but every bit helps

Stew, thanks, and oh yes, I'm having fun

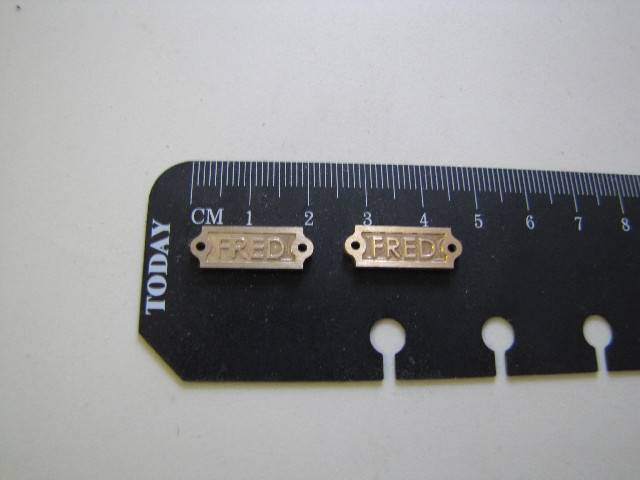

On to today's itty bitty bit - some domestic issues interfered...

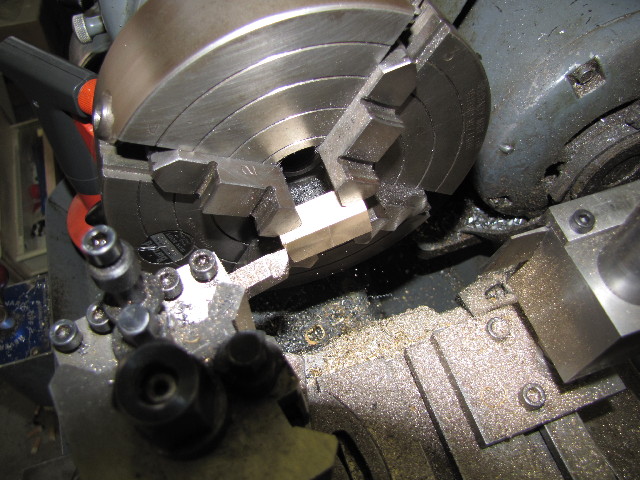

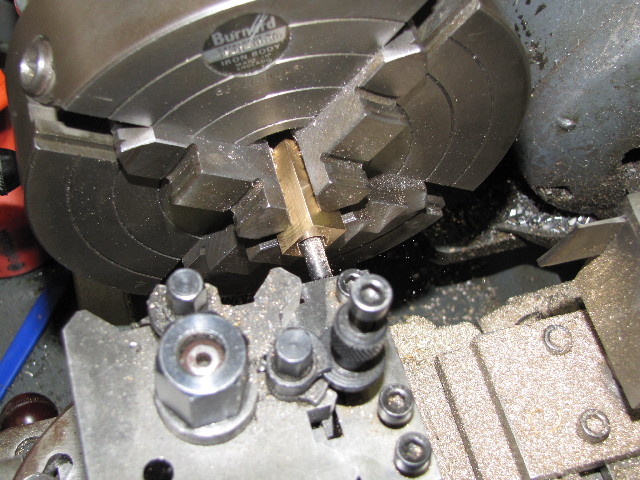

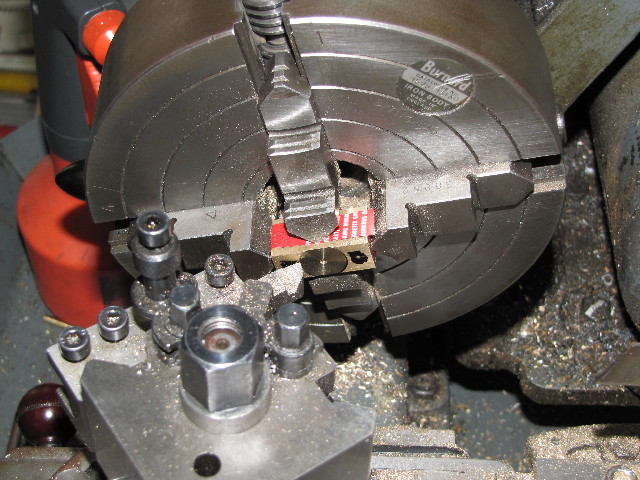

Finished off the cylinder blocks; I nearly got caught by an error on the plans. I'm basically building to the metric sizes. Dave specified the metric hole in the cylinder block for the trunnion pin as 2.5mm, but the pin itself as 2mm - that's a big difference. The imperial measurements are both specified as 3/32" - so I just settled on 2mm for both the holes and the pin. Conveniently, my 2mm center drill goes to exactly the right depth before starting to cut for a 60 degree center, so it made getting the correct depth easy. Here a photo of work on one of the cylinder faces - trunnion hole drilled 2mm, and the undercut faced off:

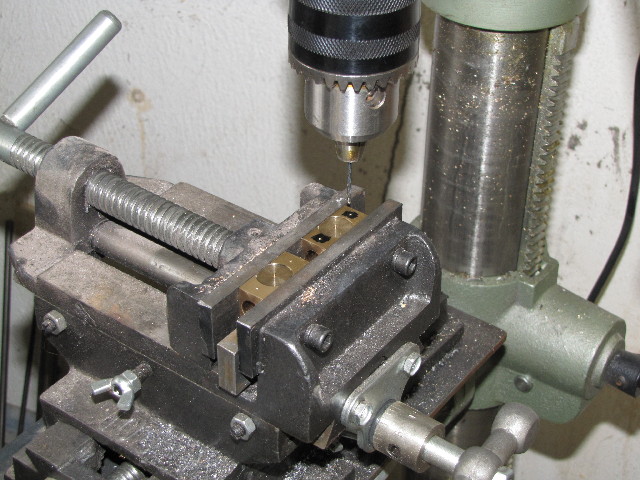

After finishing the other cylinder the same way, I moved to the drill press & drilled the port holes:

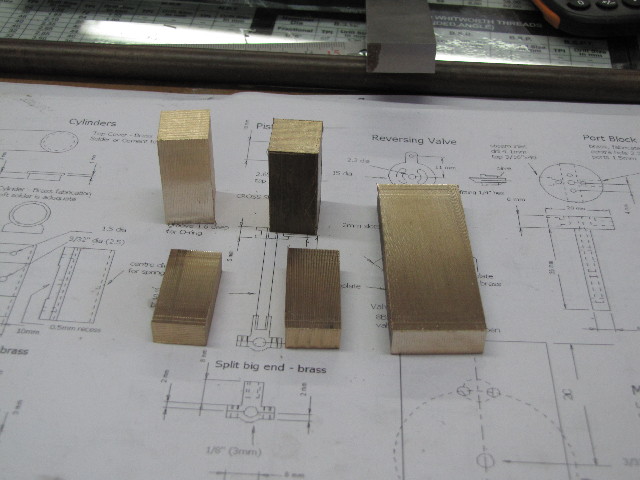

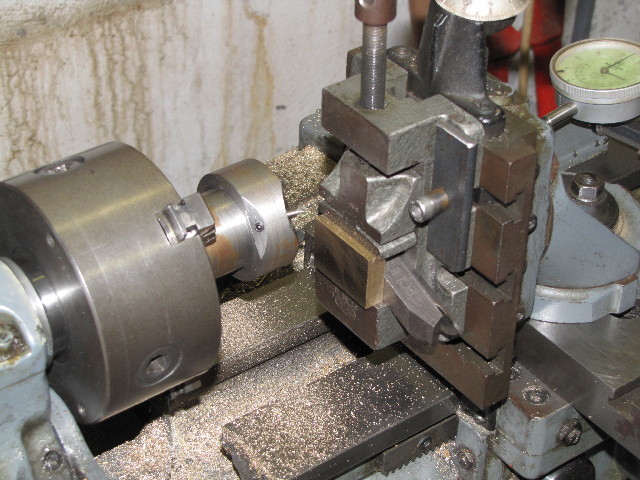

Then I set up the lathe with the vertical slide and flycut & milled the piece of brass for the port block to size:

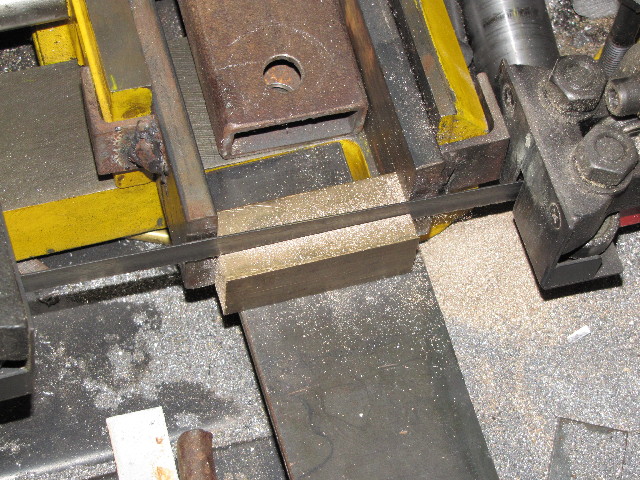

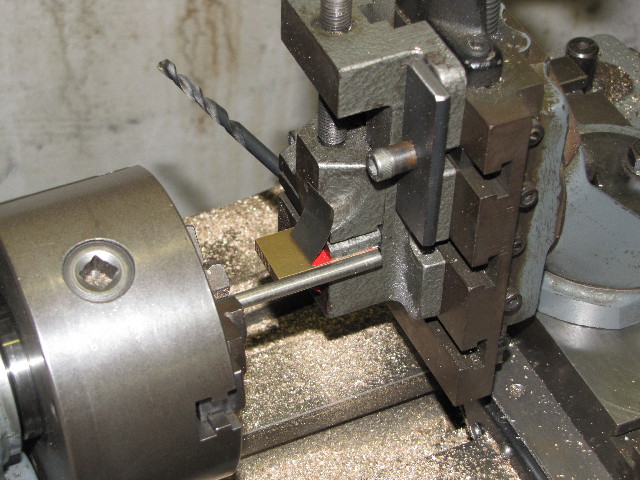

With slightly un-square (is that a word?) top and bottom on the port block from the bandsawing, this is the method I used to set up to mill them square - the drill sticking out at the other end of the vice is to keep spacing correct across the jaws:

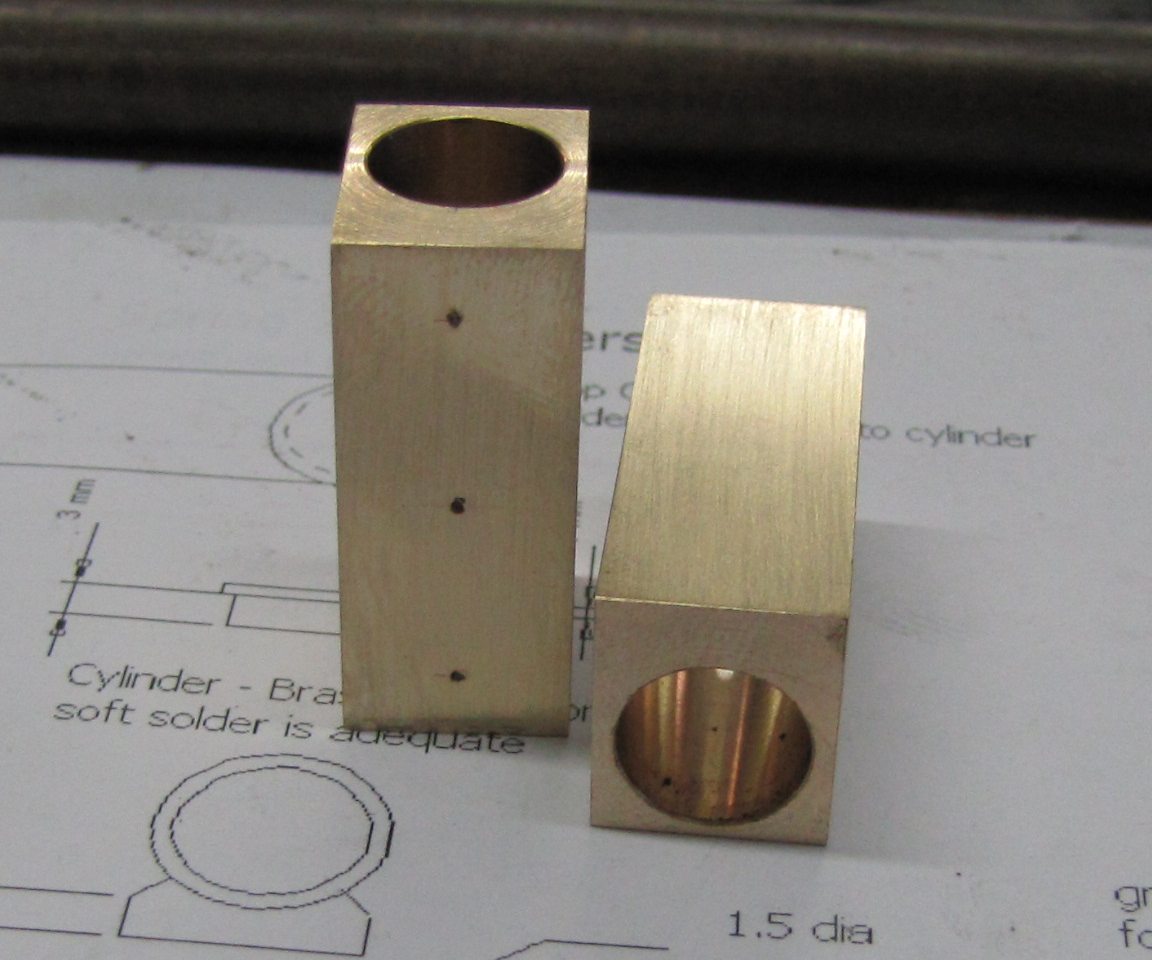

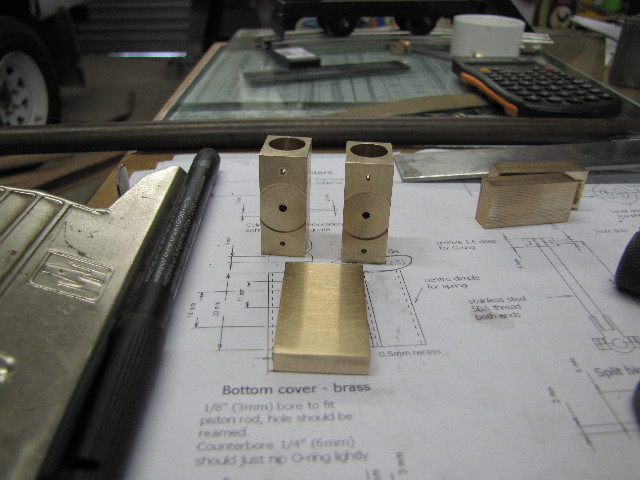

I stopped work on Fred today with the finished cylinder blocks, and the port block ready for layout and some very deep drilling... :

Regards, Arnold