arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

nkalbrr, Zee & Dean - Thank you for checking in guys

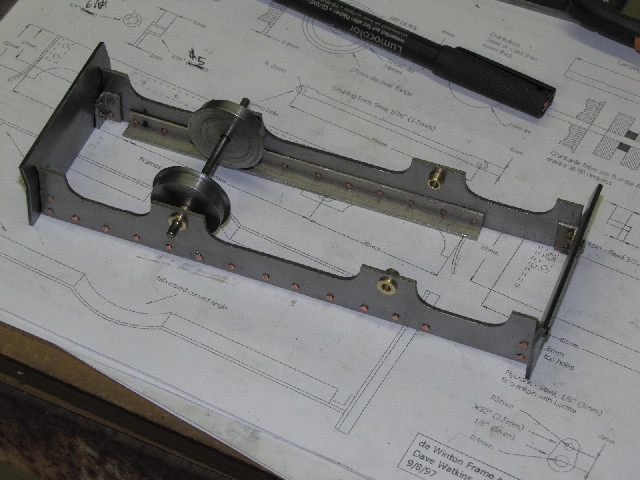

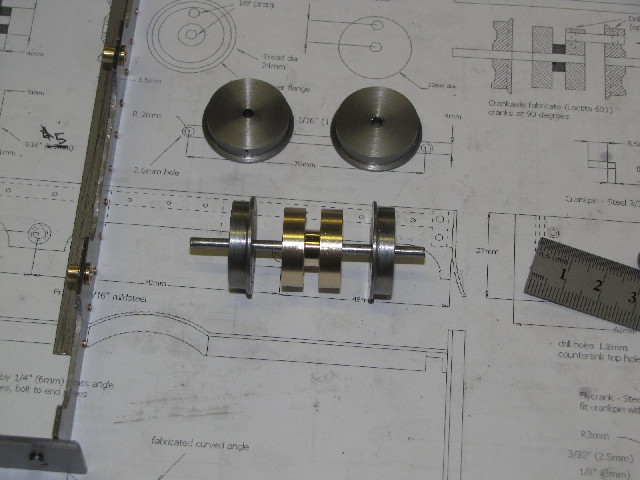

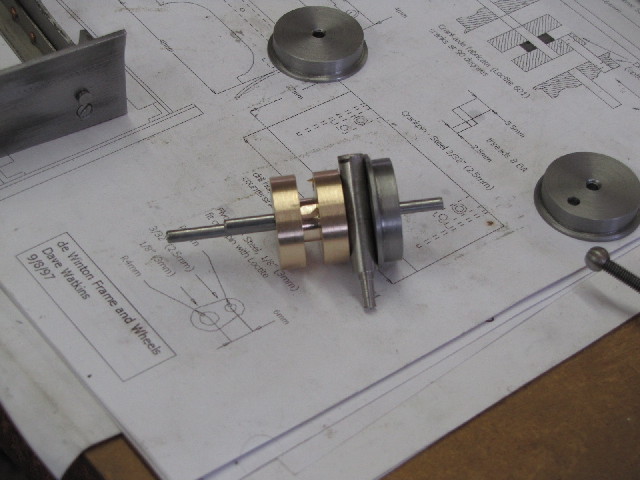

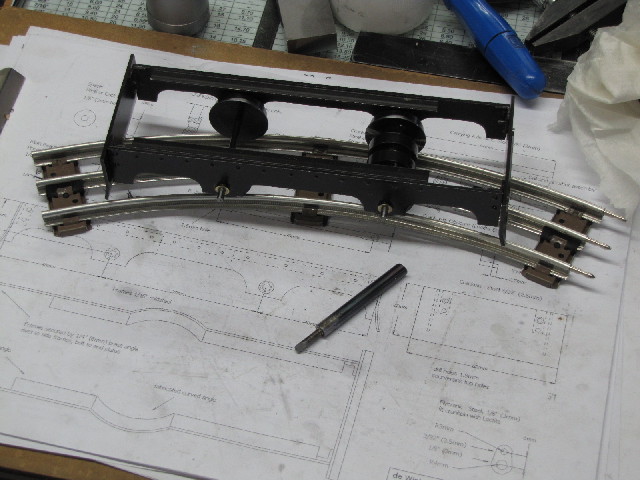

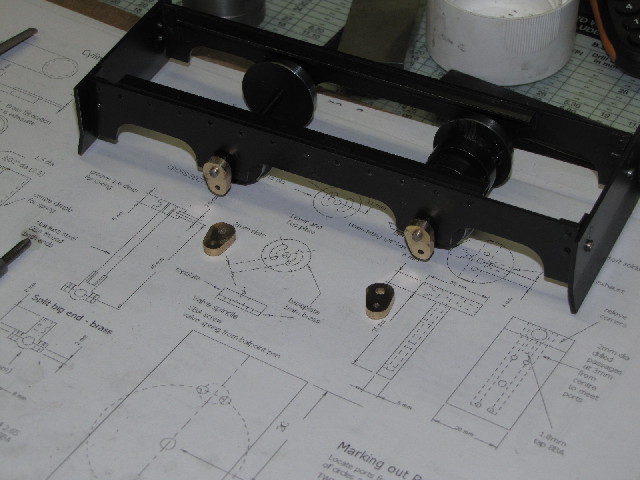

nkalbrr - I wasn't very particular with the rail - just as cheap as I could get ;D. I downloaded the plans from the john-tom site; it's the Dave Watkins DeWinton. If you're interested in building it, I would seriously recommend Dave's build "log" document as well; you can find it on his home site Here as "Idris Story". I'll be building a sort of "outside" RR on my front porch

Zee, thank you; it is an enormous bonus to know that some of my work can actually inspire someone - and to be told so is great honour.

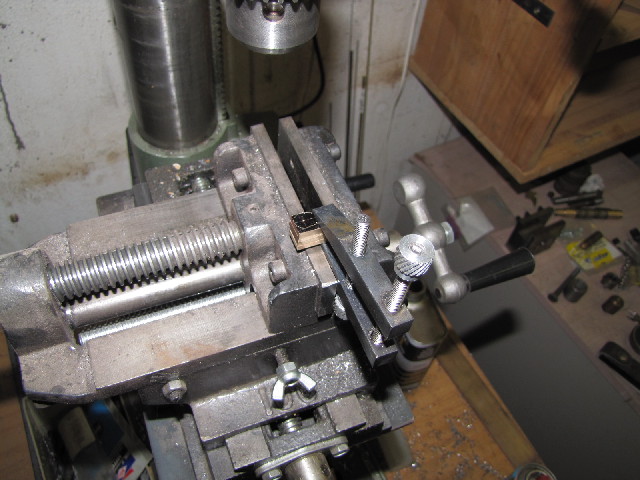

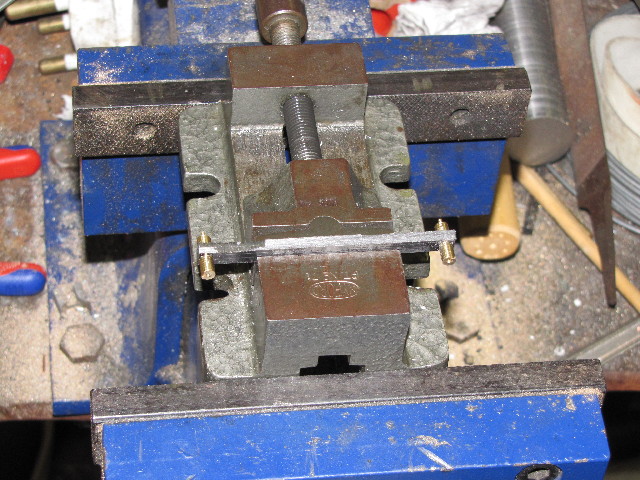

Dean, my thoughts exactly; I anyway have to make a jig to hold the screws for slotting for the countersink ones and making hex heads on the visible ones.

Kind Regards, Arnold

nkalbrr - I wasn't very particular with the rail - just as cheap as I could get ;D. I downloaded the plans from the john-tom site; it's the Dave Watkins DeWinton. If you're interested in building it, I would seriously recommend Dave's build "log" document as well; you can find it on his home site Here as "Idris Story". I'll be building a sort of "outside" RR on my front porch

Zee, thank you; it is an enormous bonus to know that some of my work can actually inspire someone - and to be told so is great honour.

Dean, my thoughts exactly; I anyway have to make a jig to hold the screws for slotting for the countersink ones and making hex heads on the visible ones.

Kind Regards, Arnold