Vernon, Dennis, CC, Bob, Zee, Dean, Tony, Joe and Kevin, Thank you all for your positive support and feedback ;D

Some good news, and some bad news... Good news, Fred Runs ;D - bad news; You'll have to wait for a lot of pictures to load :big:

I've been quiet the last couple of days; first up, a major thunder storm and high winds kept me away from the shop on 28/01 - No use; as a power outage is nearly certain:

Yesterday evening's work:

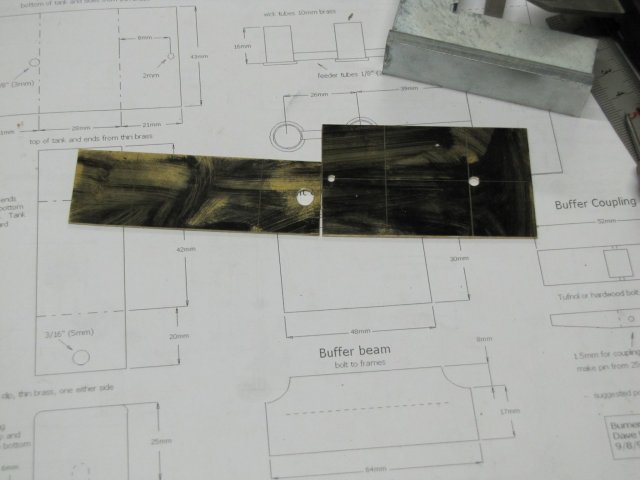

Brass plate laid out for a burner reservoir; after layout, and scoring out deepish marking lines, I annealed the plates:

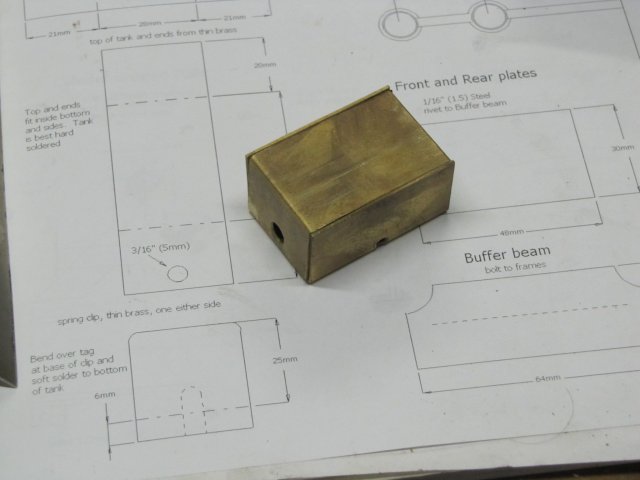

And bent the lot to size using my big vise and a hammer:

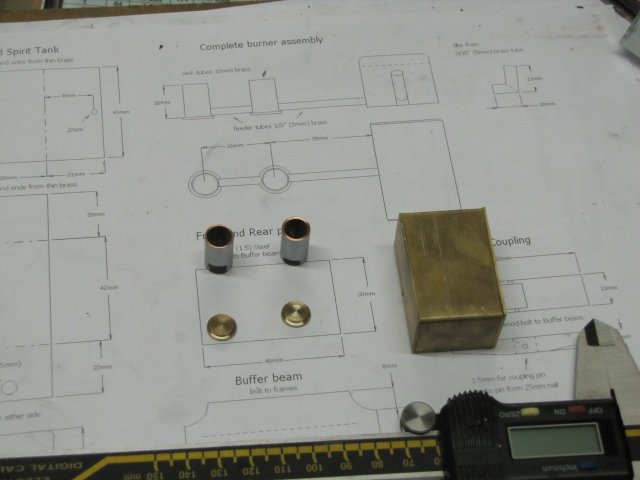

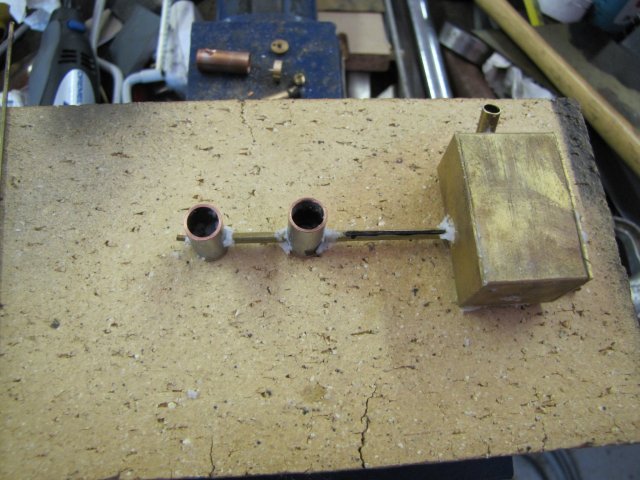

Then I made some more bits for the burner; wick tubes & bottoms:

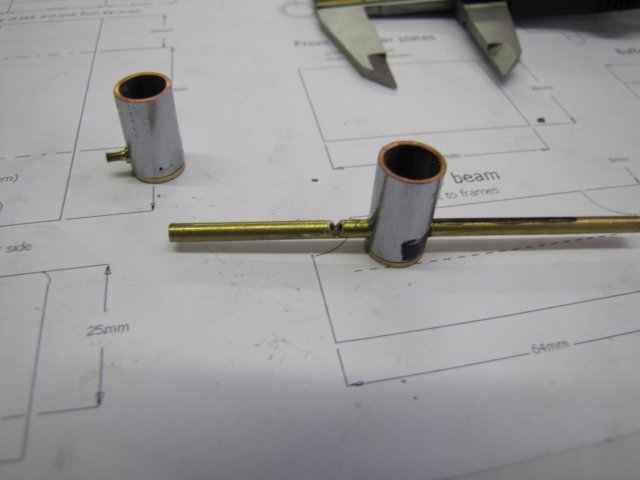

Drilling the wick tubes for the feed pipe:

The feed pipe with a V-notch filed in it for the first wick tube. I made a booboo on the end wick tube; instead of drilling just one side, I drilled it through, so I used a bit of "scrap" that happened to be threaded M2 in the extra hole. The booboo in this case turned out to be useful for mounting the burner to the loco!:

Filler pipe for the burner; from some 5mm brass tube; Filed down to bend it to about 80 degrees and then solder up:

Burner assembly ready to silver solder:

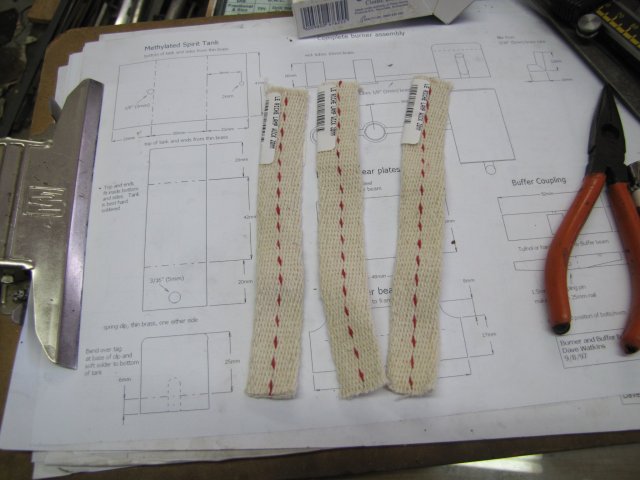

For a change, something cheap came my way ;D With a lot of people here in Namibia with a very low income, many don't have electricity, and paraffin lamps are still widely used, so wicks are available everywhere. A pop in to my closest grocer, and I have 3 pieces of wicking at N$ 1.25 each; that's US$ 0.17:

While the burner was laying in the pickle, I got to work on a "track" to test Fred - no thanks to trainz.com

. I used a bit of "wheatbix" (Chip Board) left over from kitchen renovations last year:

Brown Stuff: (Wood :big

My dad kindly gave me his router that he wasn't using anymore last year, and it's been sitting in a box since then. I've never used a router in my life; so this was a first for me today. I bought two 6x12 aluminium angle lengths of 2.5m each, and calculated how to lay out a track using these on the above chip board to "make" tracks and minimise wastage. So I used the router to cut grooves in the board to fit the aliminium angle for a layout:

I miscalculated a bit :hDe:; forgot to halve the lengths of the straight run tracks for each piece, so ended up short on the tracks, so had to improvise a bit.

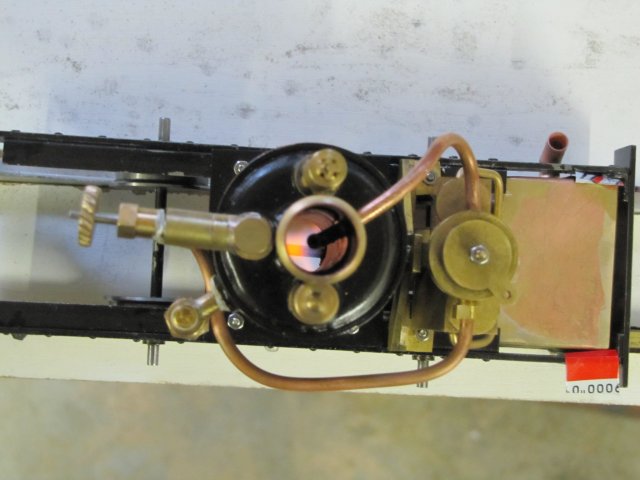

First fire-up! Glow from below boiler.

View down the chimney; Flames are a bit orange, this is caused by the wicks used for the first time:

Apologies for the crude burner mounting; a strip of soda can to hold it in place...

[youtube=425,350]<object width="425" height="344"><param name="movie" value="

http://www.youtube.com/v/gtQBUO_hOTE&hl=en_GB&fs=1&"></param><param name="allowFullScreen" value="true"></param><param name="allowscriptaccess" value="always"></param><embed src="

http://www.youtube.com/v/gtQBUO_hOTE&hl=en_GB&fs=1&" type="application/x-shockwave-flash" allowscriptaccess="always" allowfullscreen="true" width="425" height="344"></embed></object>[/youtube]

Sorry, no "finesse" this was Fred's first run on steam! - and my first steam run besides from using a pressure cooker!. Some leaks to sort out, and a LOT of hissing and sputtering. Now I'm really glad I don't have the lubricator in line - thanks Bob! - there is a LOT of condensation; maybe I have a bit of a foaming problem as well. I'll play some more tomorrow!

Regards, Arnold