arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

Once again, thank you all for your inspiring and positive responses

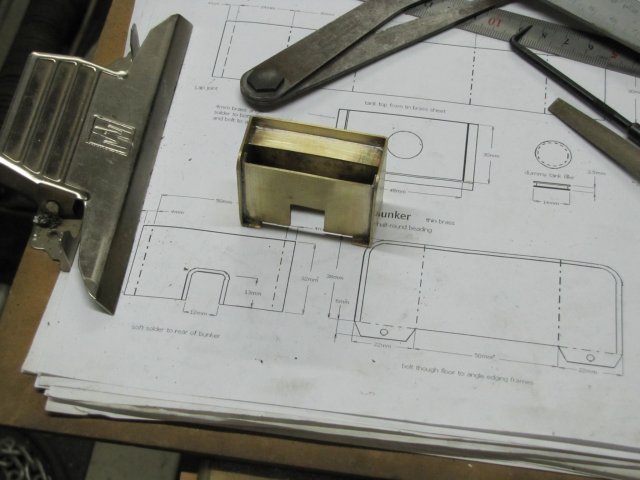

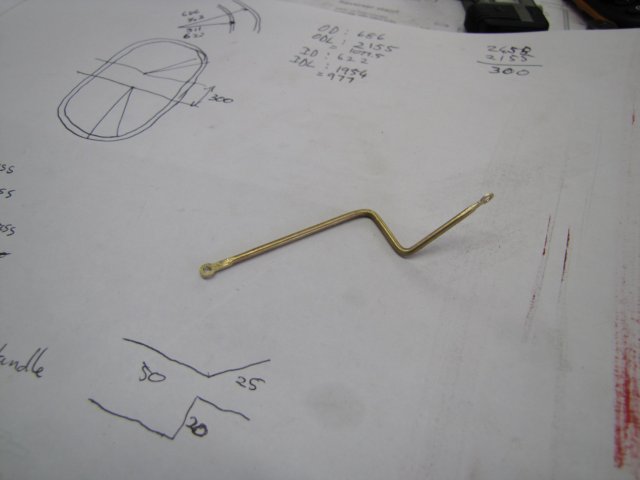

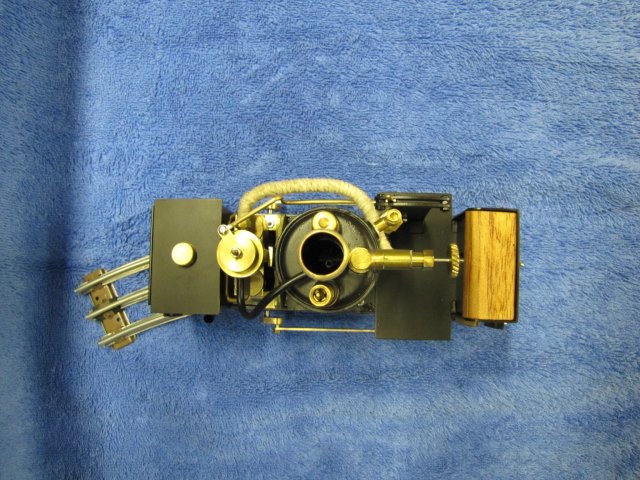

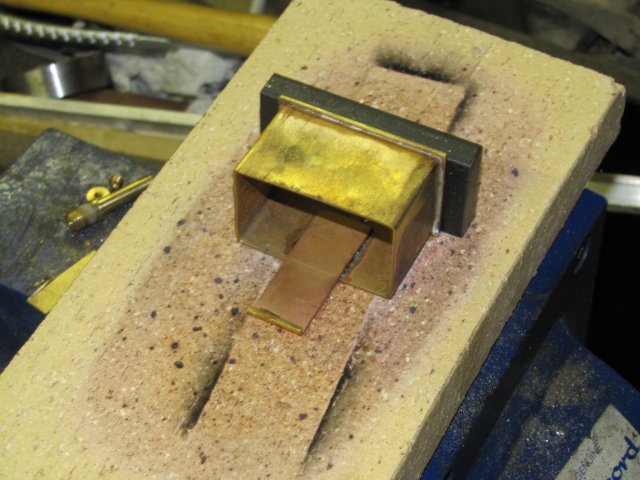

Yesterday evening I made the dummy water tank for Fred - here all soldered up with normal "flux core electronics" solder. As I didn't use any additional flux, I just cleaned all the surfaces that needed soldering well with a scouring pad. A gentle flame with the gas torch to heat things up, and the solder "takes" and wicks easily into the joints. Overheating would cause the solder's own flux to just burn off:

The extension on the bottom is actually the new burner reservoir mounting.

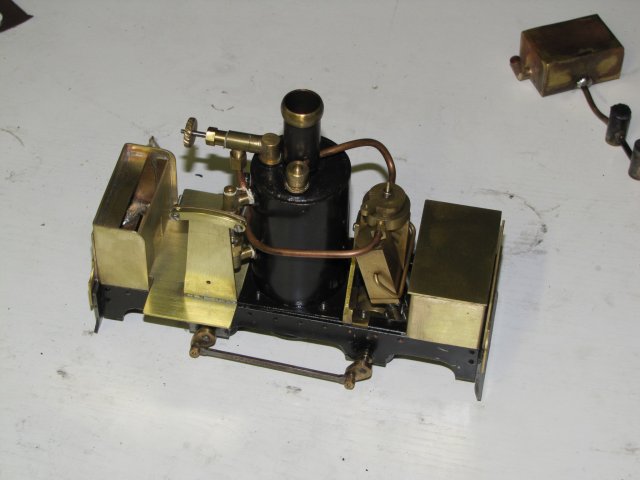

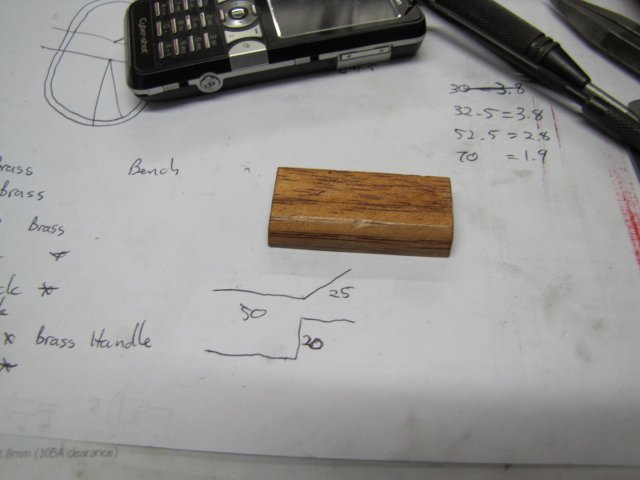

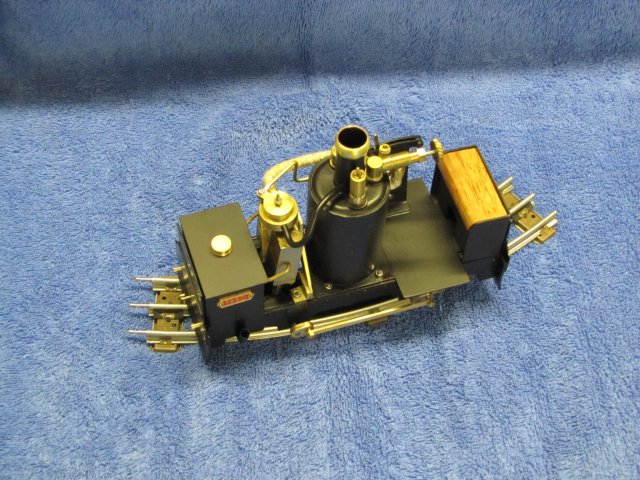

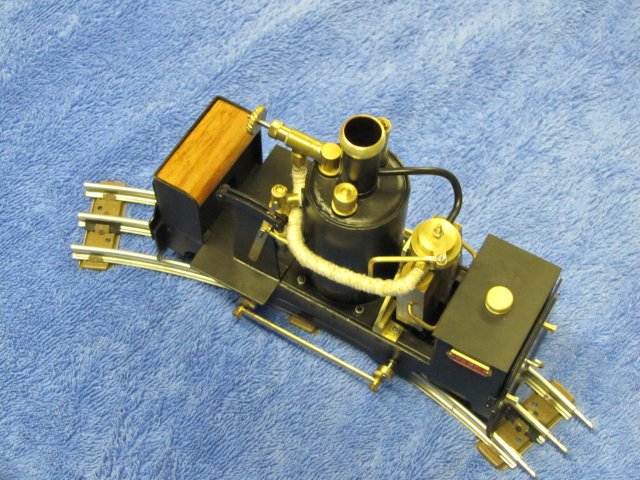

Water tank installed on the loco frames; nearly everything is disassembled for making the final bits and a good clean-up and repaint where needed:

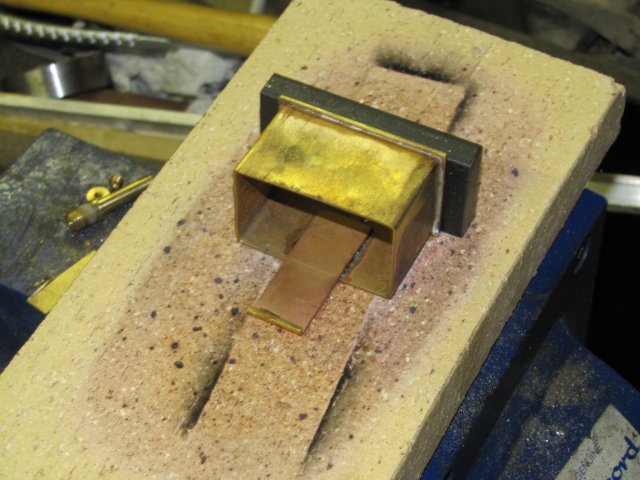

Today after work, I spent some more time on plate work making the "buffer plates" and "end plates"- and more filing. The buffer plates needed cosmetic rounding in the corners - here showing the curve needed, and the buffer plates clamped back-to-back for the job; I'd already done one side:

I just filed the corner off flat to close to the curve's end points:

Then with a half-round file with a slightly smaller radius than the curve, started to file towards the line:

And done:

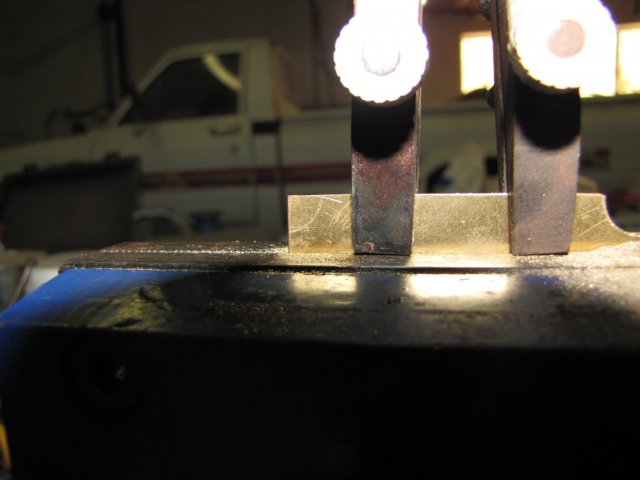

Then I made the end plates; just two pieces of rectangular brass plate, sawn & filed to shape, and soldered these to the buffer plates:

The plans are a bit vague on the buffer and end plate mounting. After having had a careful look at things, I'll mount the buffer plates using turned "buffers" rather than making a wooden buffer block like in the plans; the turned buffers will look more train-like anyway.

I stopped here for the evening, as I felt my concentration beginning to wander; that will just result in bodged parts.

Regards, Arnold

Yesterday evening I made the dummy water tank for Fred - here all soldered up with normal "flux core electronics" solder. As I didn't use any additional flux, I just cleaned all the surfaces that needed soldering well with a scouring pad. A gentle flame with the gas torch to heat things up, and the solder "takes" and wicks easily into the joints. Overheating would cause the solder's own flux to just burn off:

The extension on the bottom is actually the new burner reservoir mounting.

Water tank installed on the loco frames; nearly everything is disassembled for making the final bits and a good clean-up and repaint where needed:

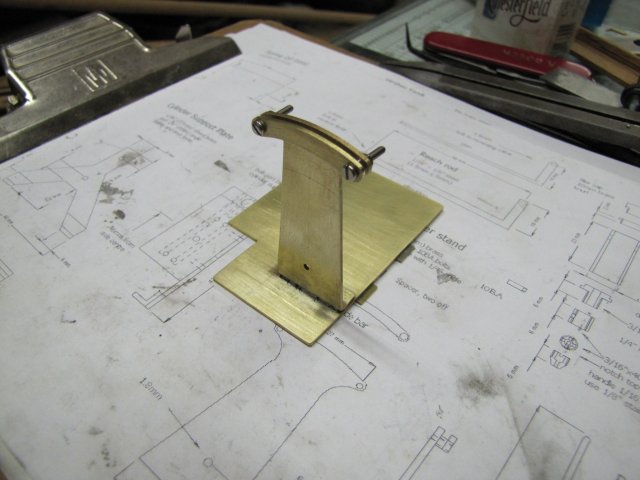

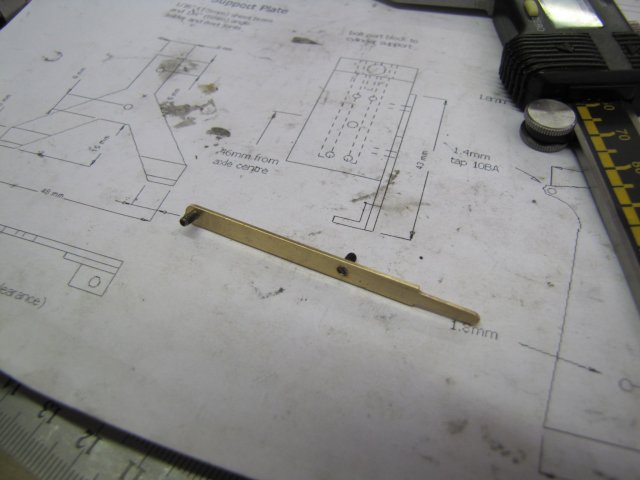

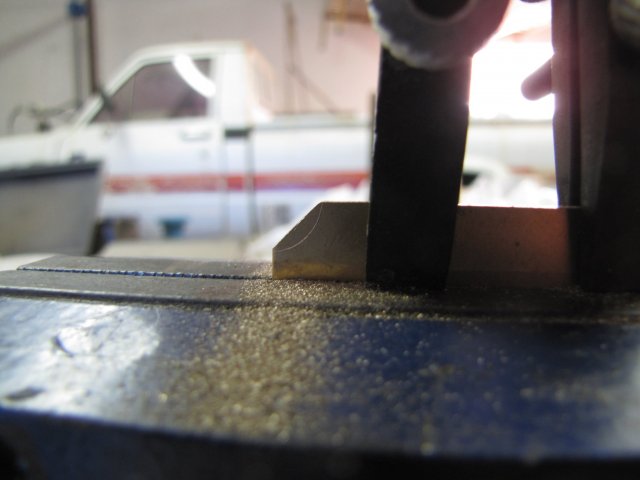

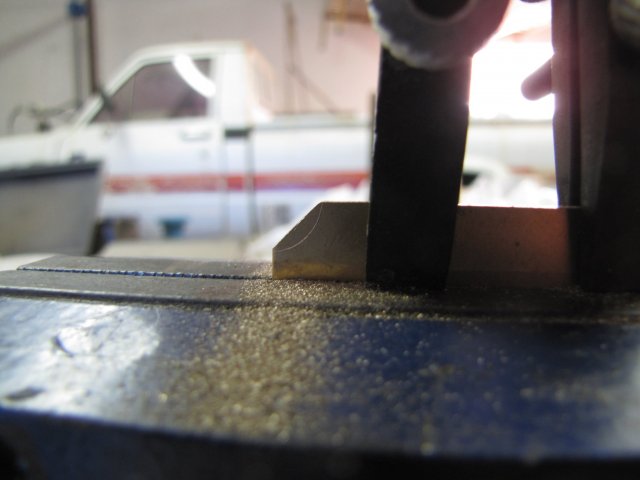

Today after work, I spent some more time on plate work making the "buffer plates" and "end plates"- and more filing. The buffer plates needed cosmetic rounding in the corners - here showing the curve needed, and the buffer plates clamped back-to-back for the job; I'd already done one side:

I just filed the corner off flat to close to the curve's end points:

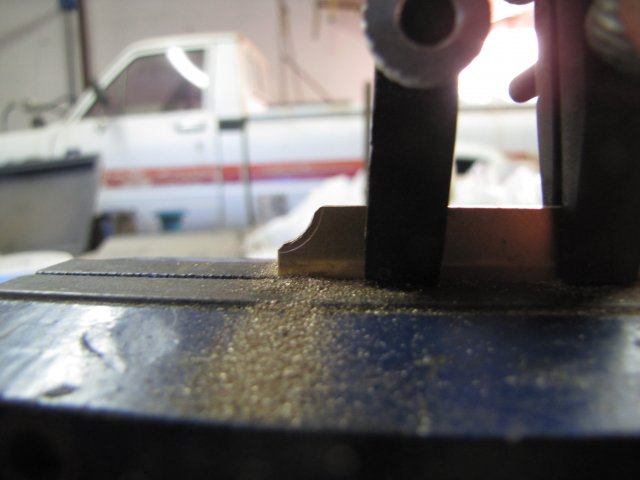

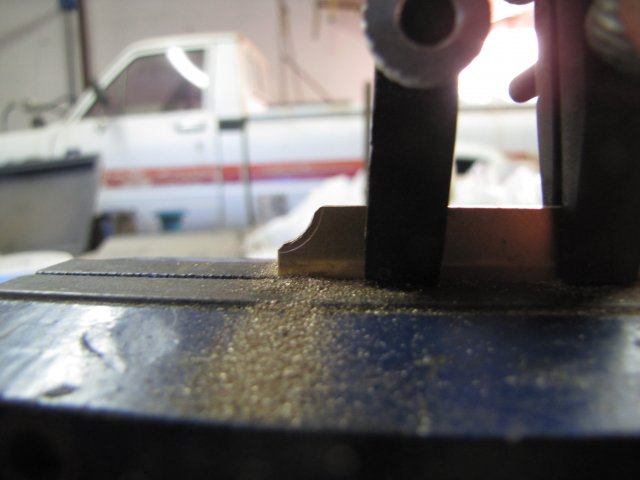

Then with a half-round file with a slightly smaller radius than the curve, started to file towards the line:

And done:

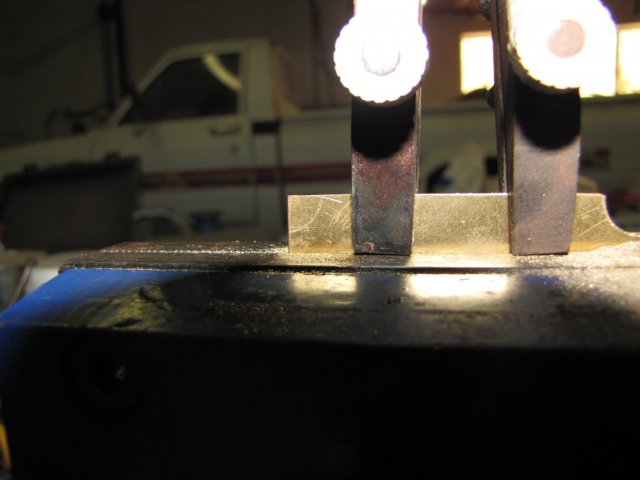

Then I made the end plates; just two pieces of rectangular brass plate, sawn & filed to shape, and soldered these to the buffer plates:

The plans are a bit vague on the buffer and end plate mounting. After having had a careful look at things, I'll mount the buffer plates using turned "buffers" rather than making a wooden buffer block like in the plans; the turned buffers will look more train-like anyway.

I stopped here for the evening, as I felt my concentration beginning to wander; that will just result in bodged parts.

Regards, Arnold