arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

While building Elmer's Grasshopper, I saw that I could really do with an RT for my mill. I'm still broke from buying the mill, and an RT is pretty expensive here in Namibia.

Some research turned up bits and pieces of information on RTs, and then I hit gold on Dean's build of his rotary table - excellently detailed as always by Dean - and the plans available there. Thank you both Dean and Steve :bow:

My build is based on Dean's, but I'm adapting some dimensions and methods to the materials and tools I have available, as well as changing some bits to suit my own needs.

Some of the things I want from the RT are:

1. Use as much material as possible from what I have on hand or can economically obtain

2. An adapter to take any of my Myford chucks and to do machining securely on it.

3. Adjustment of backlash on the worm drive - and full disengagement of the drive for "quick indexing"

4. Accuracy to 0.1 degrees or better from the hand wheel, with an option to add dividing plates as needed.

5. Compatibility with as much of my existing tooling as I have.

As I have to make the worm and gear, I decided on a 72 tooth gear; that gives 5 degrees per turn of the hand wheel and should make things easy to use.

For the last couple of weeks, I've sourced and scrounged whatever materials I would need for the build; some I had lying around, and a lot I had to buy. I ended up with: Some bits of 10x60mm flat bar and a bit of 12mm plate for the base, a lump of cast iron for the table, phosphor bronze to make the gear out of, an old bit of bolt for some material to make diverse bits, aluminium for the handwheel, a brand new angular contact bearing, a bit of shaft from a printer with 2 small bearings to salvage for mounting the hand wheel shaft, and some 8mm and 16mm silver steel to make the shaft, worm and gear cutter from:

I started on the base; the bit of 12mm plate I had was too big, so I sawed it down in the bandsaw. It was a bit too big for the bandsaw as well; so I started with as much as possible of the plate clamped in the saw vise:

Then, when the saw frame bottomed on the plate, I flipped the plate around with less clamped to finish the last bit :

The last cut was done in one go, and I ended up with the RT base plate and some left-over bits of 12mm thick plate for other projects:

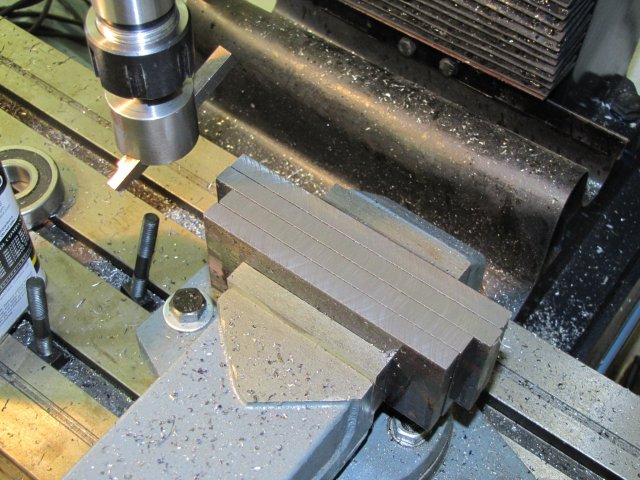

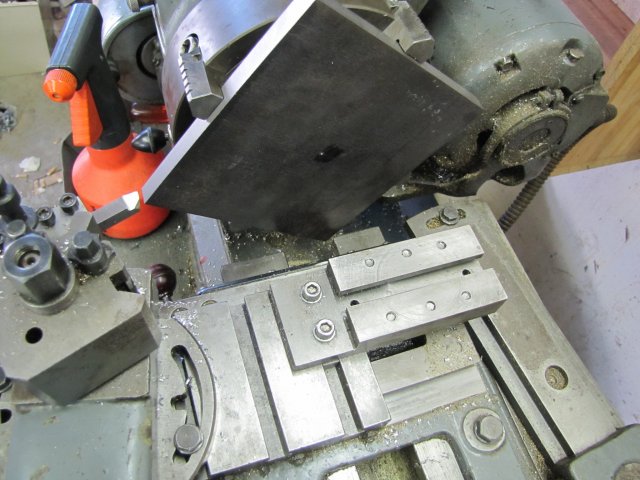

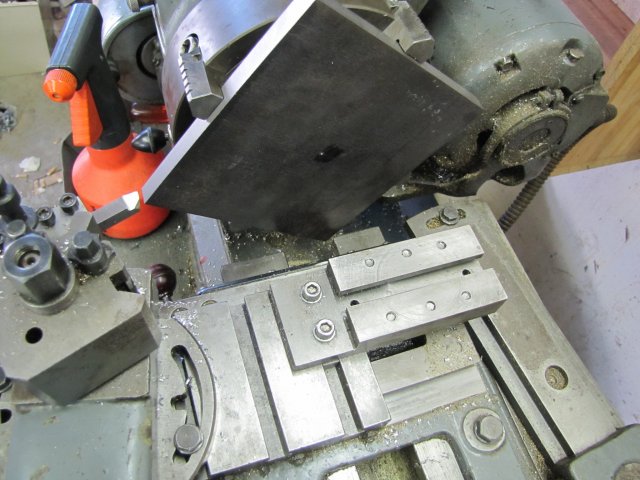

Then I clamped the plate to the mill table with some bits from the clamping kit and supported on two identical bearing outer rings as spacers, and milled three of the four sides square, with the two opposing sides I could get to, to the exact width for the plate (140mm):

The last side of the plate was done by adding an additional small clamp on the opposite completed side to keep the plate in position, and then moving the main clamps over to the finished side as well to clamp down properly to mill the last side both square and to dimension.

Fortunately, I could chuck the plate in the 4-jaw on my lathe; this makes it easy to face and bore the hole for the bearing. The corners barely clear the bed while swinging in the head-gap. :

To prevent the corners of the plate from hitting the apron while feeding, I just used the top slide to offset the toolbit enough. The cross slide is pretty close to maximum extension as well!

With the old Myford in medium back gear speed, I started the biggest facing cut I have tried to date. It took a while; very slow infeed at the start with interrupted cuts, and looking at the chips coming off to increase feed rate towards the center. Not a pretty picture, but the "ringy bands" looks worse than they are actually:

:-[ - I think some of those "bands" was caused by lighting a cigarette or two during the facing process

Next I center drilled, the plate, and drilled an 8mm hole through it with the lathe running at its second highest speed, followed by a 19mm drill (the biggest I have) in high back gear speed:

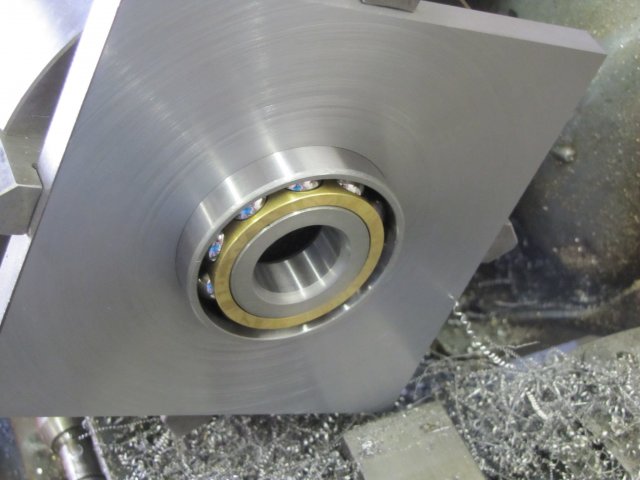

Then I bored the hole bigger; (from 19mm to 61.97 mm) I started with a cheapy tungsten carbide tipped boring bar and 20 thou (~0.5mm) depths of cut and things went OK until I tried some bigger cuts. At 40 thou cuts things were going well, but then the carbide tip splintered and everything ground to a halt. Not feeling in the mood to try and re-sharpen the tool, and with the hole big enough for my favourite HSS left-hand turning tool bit to have adequate clearance, I just plonked that in and finished the cut. I intentionally left a 0.5mm thick ridge about 2mm wide at the back.That is to allow the bearing I have to be pre-loaded without the center of it actually rising up and touching the bottom of the table later on :

A test with the bearing showed that the hole is just about the right size for a press fit for the bearing, but with the plate a bit warm from machining, and the bearing cold, I decided to let everything cool down to the same temperature overnight to make sure of the final fit for the bearing.

Regards, Arnold

Some research turned up bits and pieces of information on RTs, and then I hit gold on Dean's build of his rotary table - excellently detailed as always by Dean - and the plans available there. Thank you both Dean and Steve :bow:

My build is based on Dean's, but I'm adapting some dimensions and methods to the materials and tools I have available, as well as changing some bits to suit my own needs.

Some of the things I want from the RT are:

1. Use as much material as possible from what I have on hand or can economically obtain

2. An adapter to take any of my Myford chucks and to do machining securely on it.

3. Adjustment of backlash on the worm drive - and full disengagement of the drive for "quick indexing"

4. Accuracy to 0.1 degrees or better from the hand wheel, with an option to add dividing plates as needed.

5. Compatibility with as much of my existing tooling as I have.

As I have to make the worm and gear, I decided on a 72 tooth gear; that gives 5 degrees per turn of the hand wheel and should make things easy to use.

For the last couple of weeks, I've sourced and scrounged whatever materials I would need for the build; some I had lying around, and a lot I had to buy. I ended up with: Some bits of 10x60mm flat bar and a bit of 12mm plate for the base, a lump of cast iron for the table, phosphor bronze to make the gear out of, an old bit of bolt for some material to make diverse bits, aluminium for the handwheel, a brand new angular contact bearing, a bit of shaft from a printer with 2 small bearings to salvage for mounting the hand wheel shaft, and some 8mm and 16mm silver steel to make the shaft, worm and gear cutter from:

I started on the base; the bit of 12mm plate I had was too big, so I sawed it down in the bandsaw. It was a bit too big for the bandsaw as well; so I started with as much as possible of the plate clamped in the saw vise:

Then, when the saw frame bottomed on the plate, I flipped the plate around with less clamped to finish the last bit :

The last cut was done in one go, and I ended up with the RT base plate and some left-over bits of 12mm thick plate for other projects:

Then I clamped the plate to the mill table with some bits from the clamping kit and supported on two identical bearing outer rings as spacers, and milled three of the four sides square, with the two opposing sides I could get to, to the exact width for the plate (140mm):

The last side of the plate was done by adding an additional small clamp on the opposite completed side to keep the plate in position, and then moving the main clamps over to the finished side as well to clamp down properly to mill the last side both square and to dimension.

Fortunately, I could chuck the plate in the 4-jaw on my lathe; this makes it easy to face and bore the hole for the bearing. The corners barely clear the bed while swinging in the head-gap. :

To prevent the corners of the plate from hitting the apron while feeding, I just used the top slide to offset the toolbit enough. The cross slide is pretty close to maximum extension as well!

With the old Myford in medium back gear speed, I started the biggest facing cut I have tried to date. It took a while; very slow infeed at the start with interrupted cuts, and looking at the chips coming off to increase feed rate towards the center. Not a pretty picture, but the "ringy bands" looks worse than they are actually:

:-[ - I think some of those "bands" was caused by lighting a cigarette or two during the facing process

Next I center drilled, the plate, and drilled an 8mm hole through it with the lathe running at its second highest speed, followed by a 19mm drill (the biggest I have) in high back gear speed:

Then I bored the hole bigger; (from 19mm to 61.97 mm) I started with a cheapy tungsten carbide tipped boring bar and 20 thou (~0.5mm) depths of cut and things went OK until I tried some bigger cuts. At 40 thou cuts things were going well, but then the carbide tip splintered and everything ground to a halt. Not feeling in the mood to try and re-sharpen the tool, and with the hole big enough for my favourite HSS left-hand turning tool bit to have adequate clearance, I just plonked that in and finished the cut. I intentionally left a 0.5mm thick ridge about 2mm wide at the back.That is to allow the bearing I have to be pre-loaded without the center of it actually rising up and touching the bottom of the table later on :

A test with the bearing showed that the hole is just about the right size for a press fit for the bearing, but with the plate a bit warm from machining, and the bearing cold, I decided to let everything cool down to the same temperature overnight to make sure of the final fit for the bearing.

Regards, Arnold