- Joined

- Jan 3, 2008

- Messages

- 2,085

- Reaction score

- 17

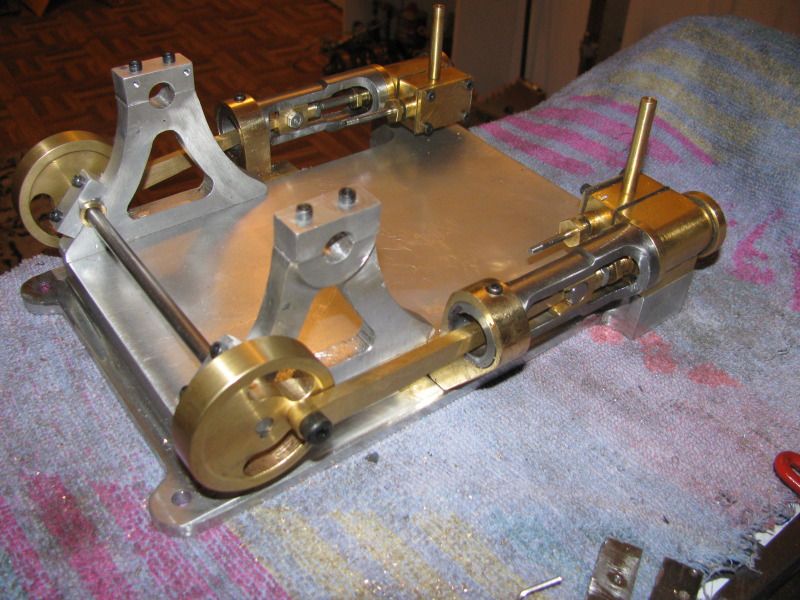

Itsi all still looking great Brian. The broaching shouldn't present any problem. Is the window for the 26 degree set screw hole large enough to let a center drill in there so you can keep the drill on the correct angle? Keep up the amazing progress

Bill

Bill