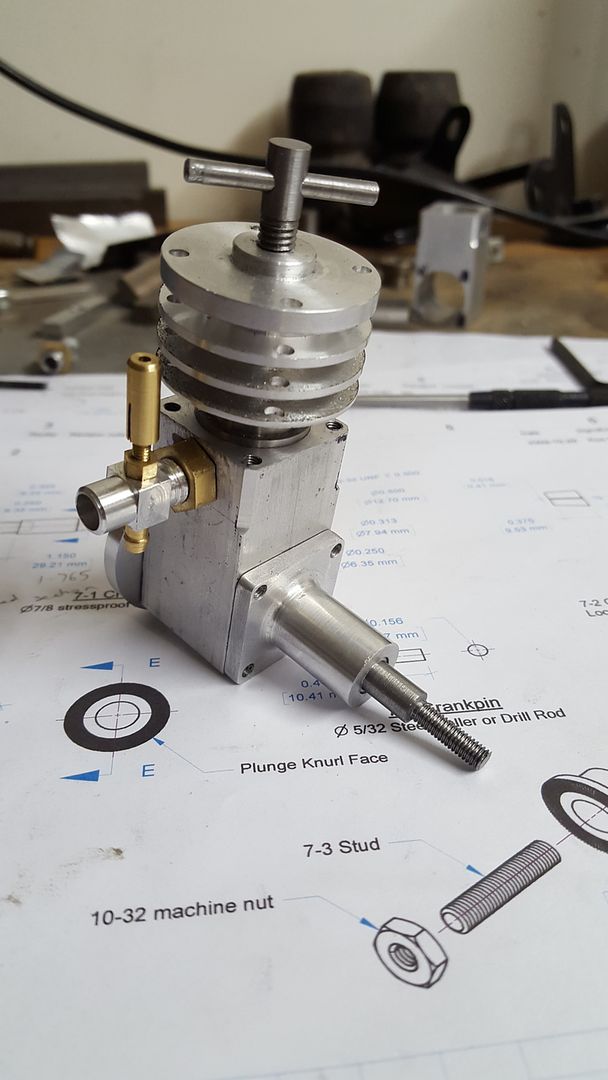

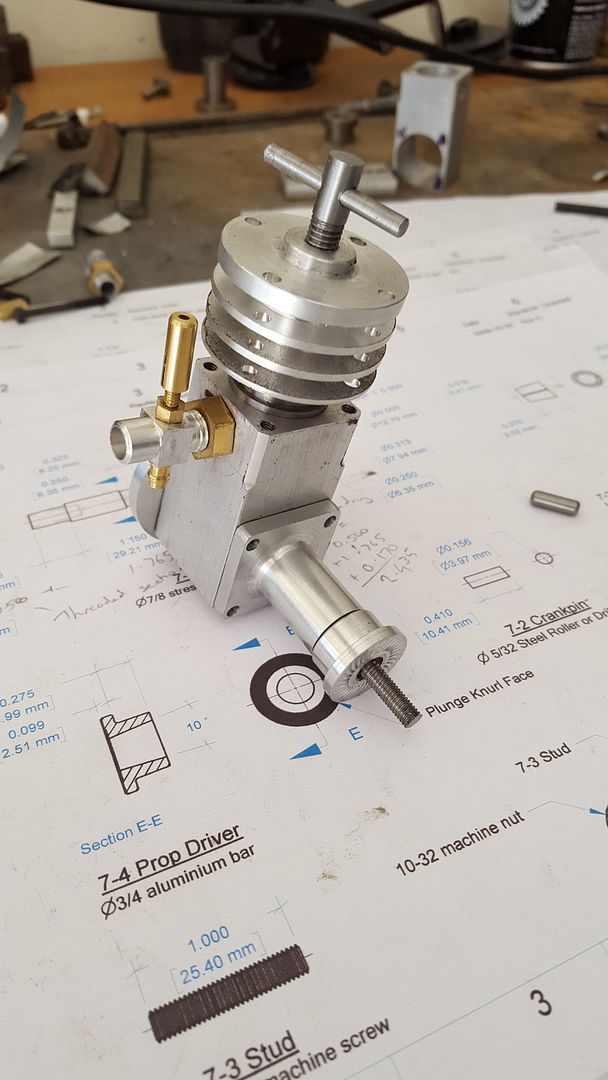

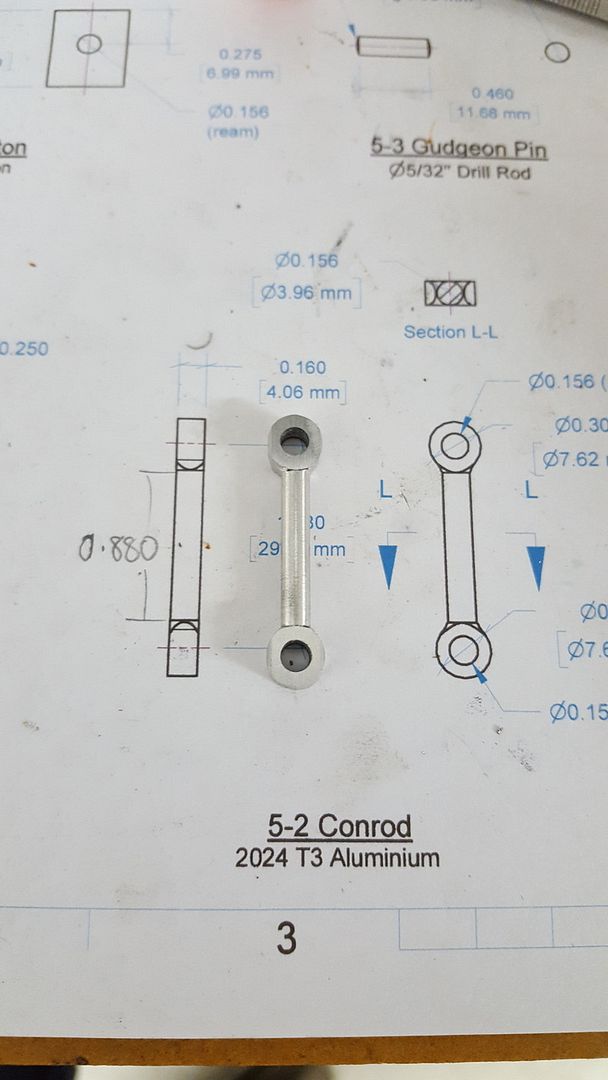

Wow - it's been a while since I've had time to update this thread. Lot's of family commitments have meant I've not had much time in the workshop over the last few weeks. I have had a couple of failed attempts at producing the conrod though...

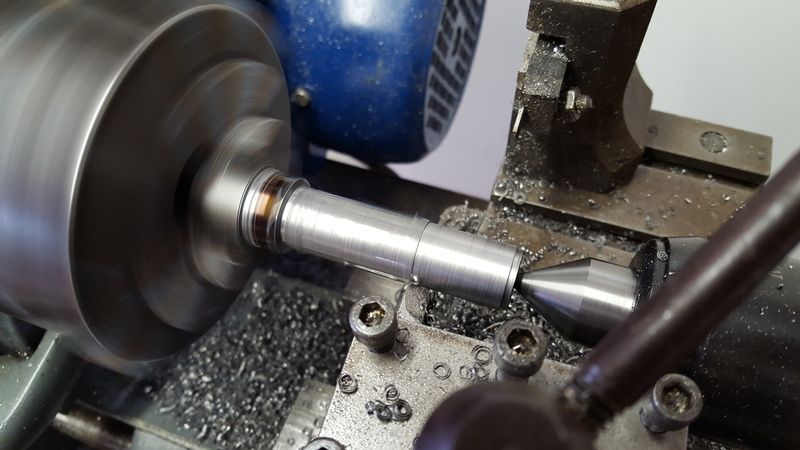

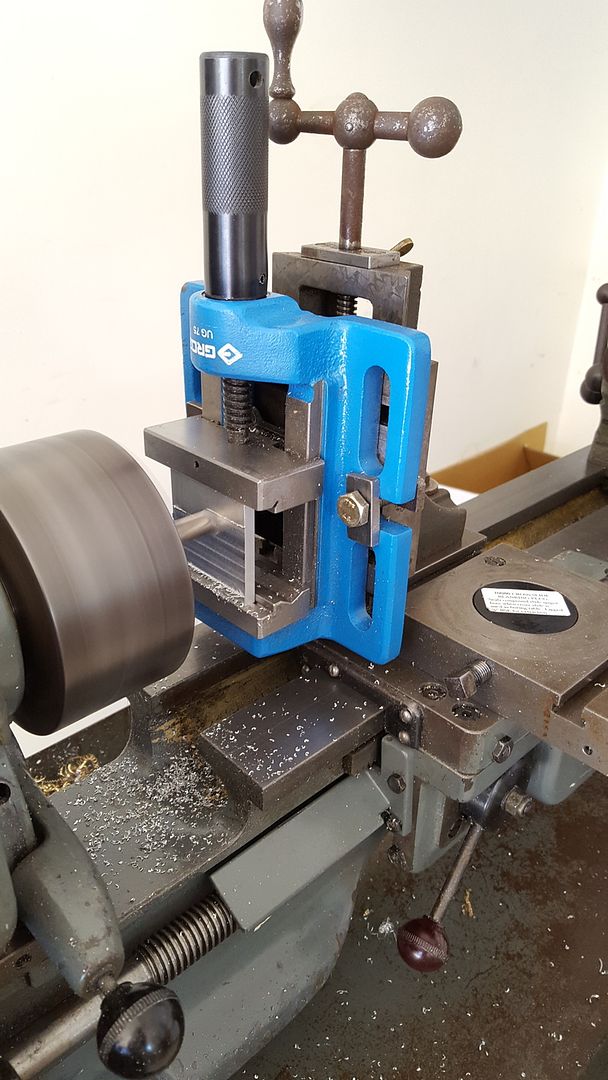

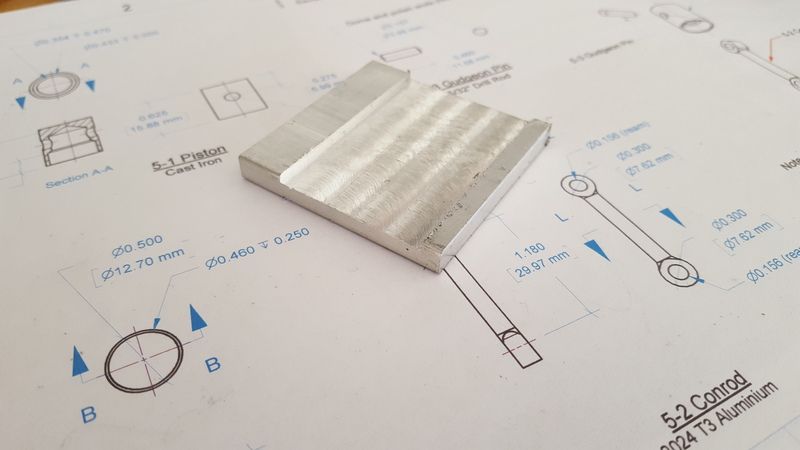

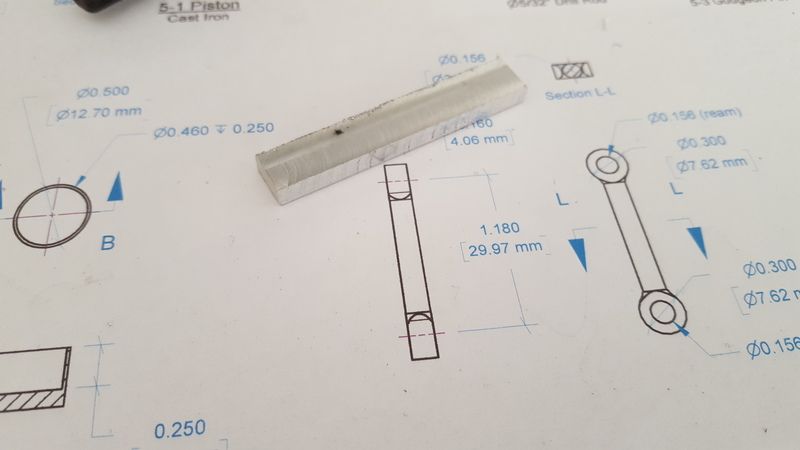

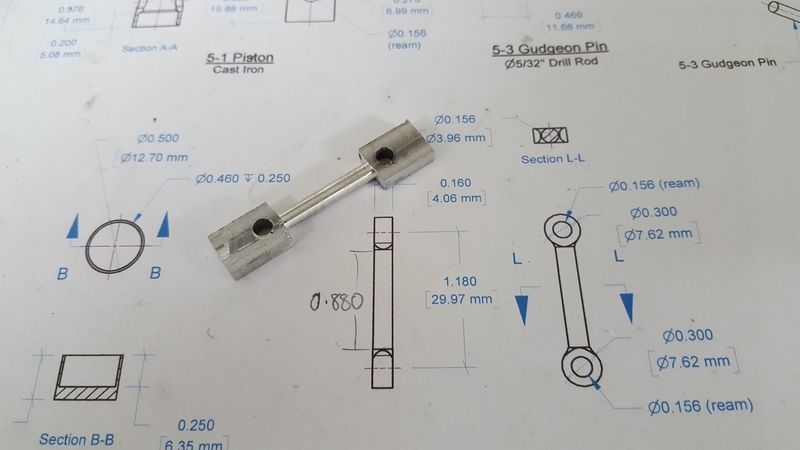

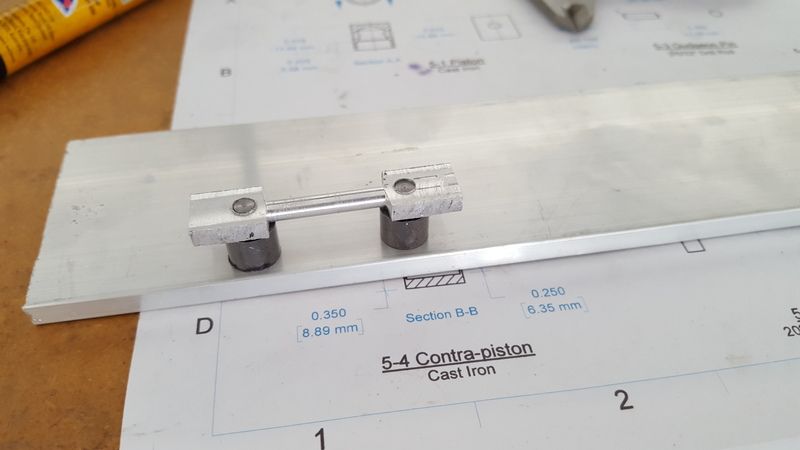

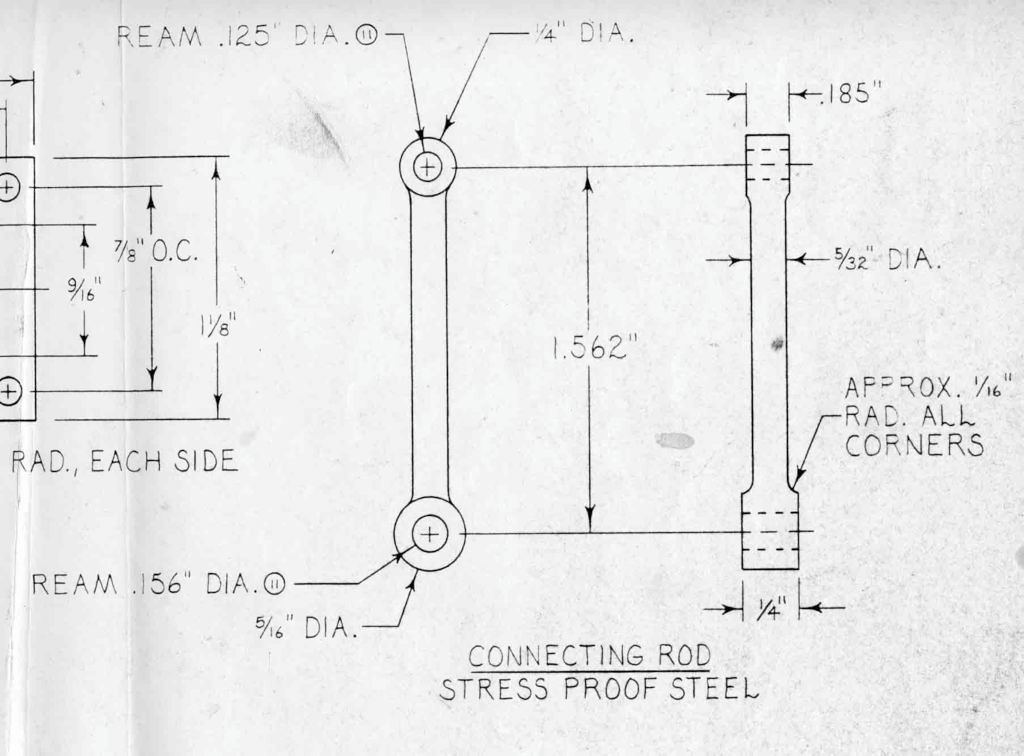

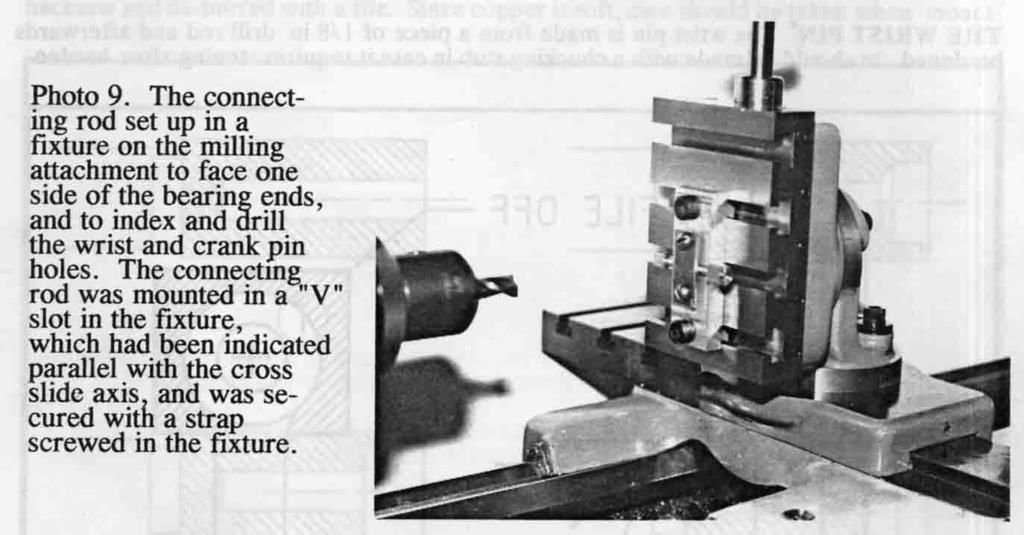

My first approach which I had started on in the previous post was to turn a section of flat aluminium and then mill the radius' on either end. At first this looked like it was going to work out reasonably well. I had turned the centre of the rod and drilled and reamed the pin holes and was reasonably happy with the result.

I had then planned to emulate an approach I'd seen on another website where a clever chap had built a modified version of the Boll Aero which he has called the

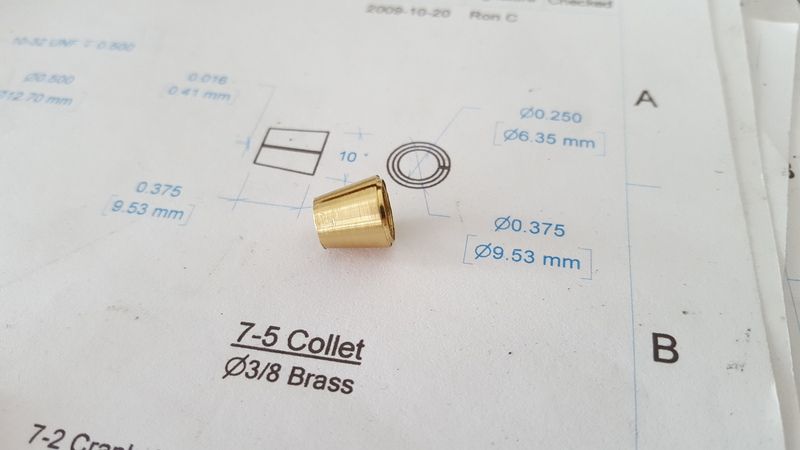

Nelson 2cc. At the bottom of that page is a picture what I thought was a rather clever approach to turning the conrod. The next sequence of photos show my attempt to replicate that approach.

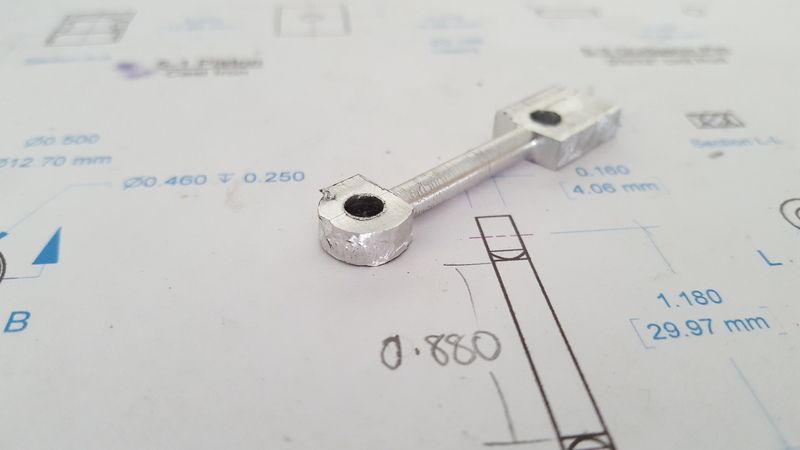

As the last couple of photos show, my result was less than ideal. My setup clearly had way to much flex and play in it and the conrod bounced about during milling. It felt a bit dodgy, and eventually the mill bit and twisted the conrod and gouged the shaft.

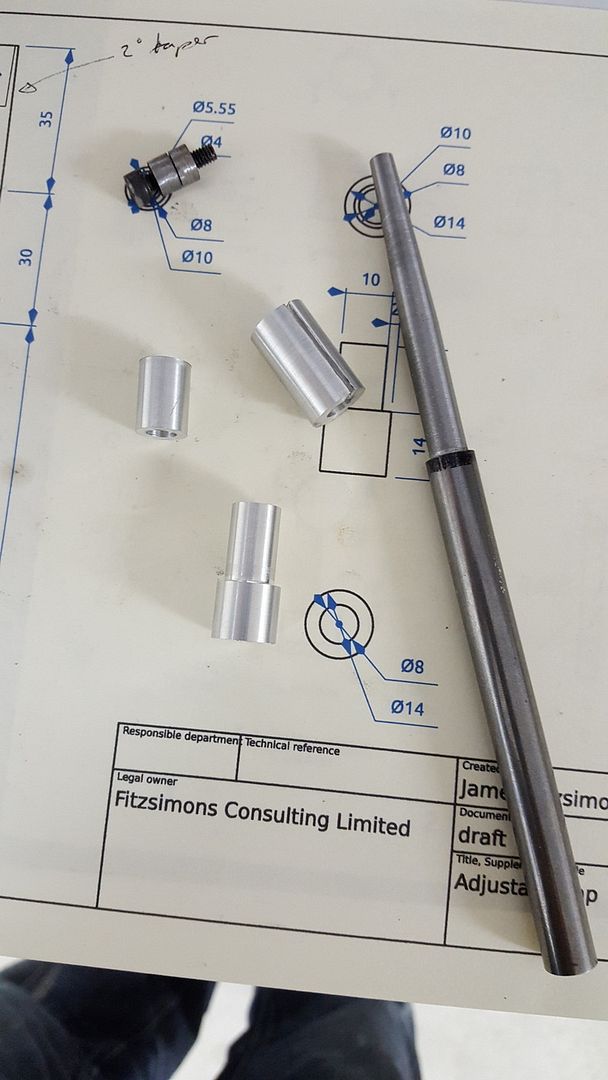

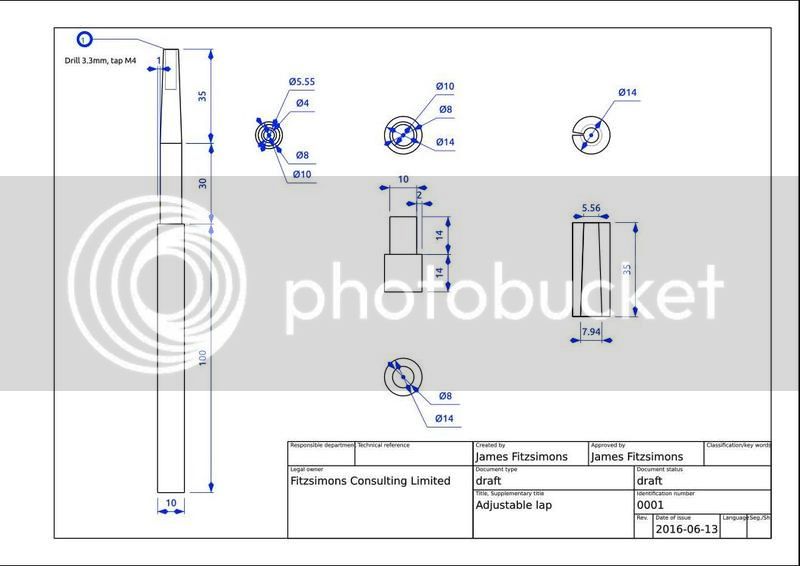

I wasn't feeling to optimistic about this approach so decided to try an new tactic. I had seen an alternative way of making conrods as described by Ramon Wilson in his

5cc Super Tigre build.

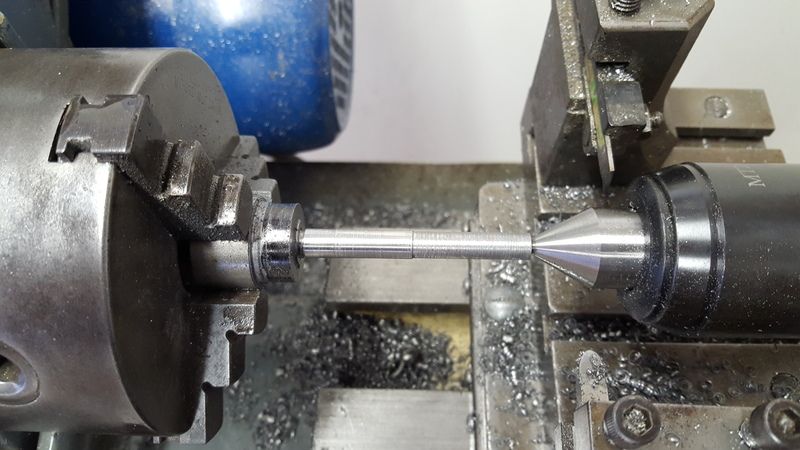

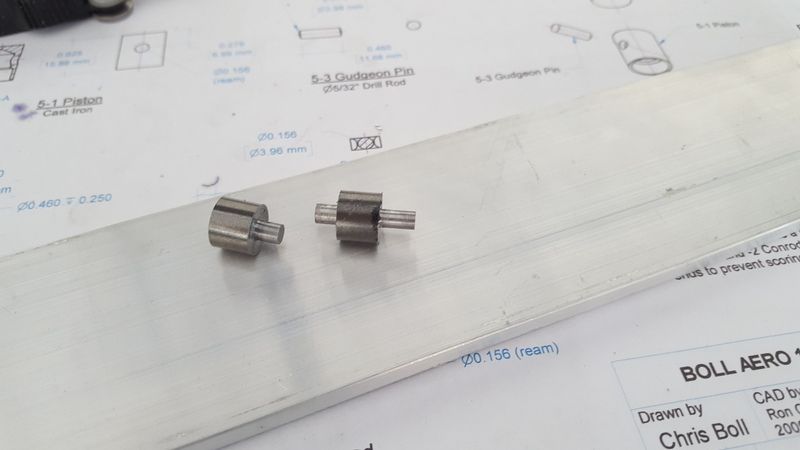

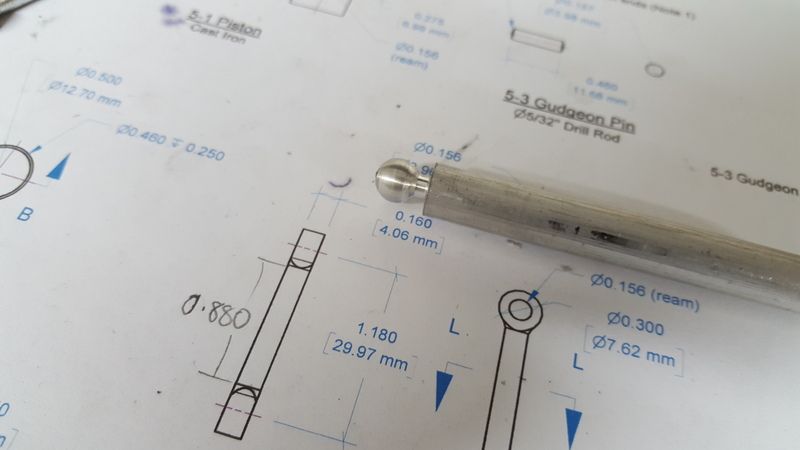

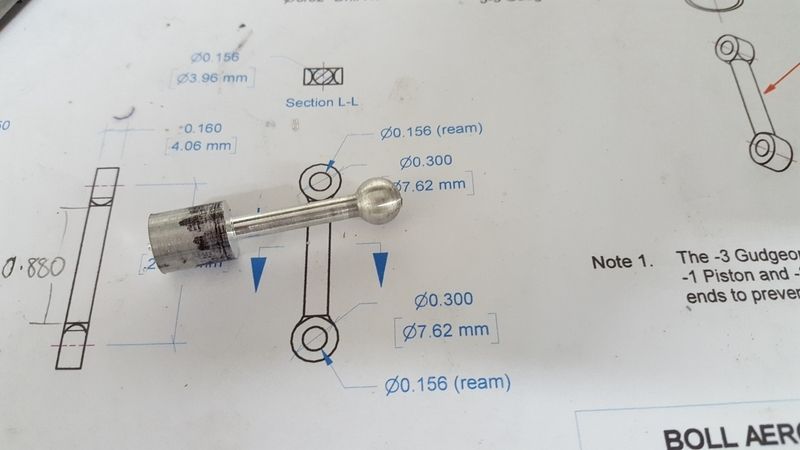

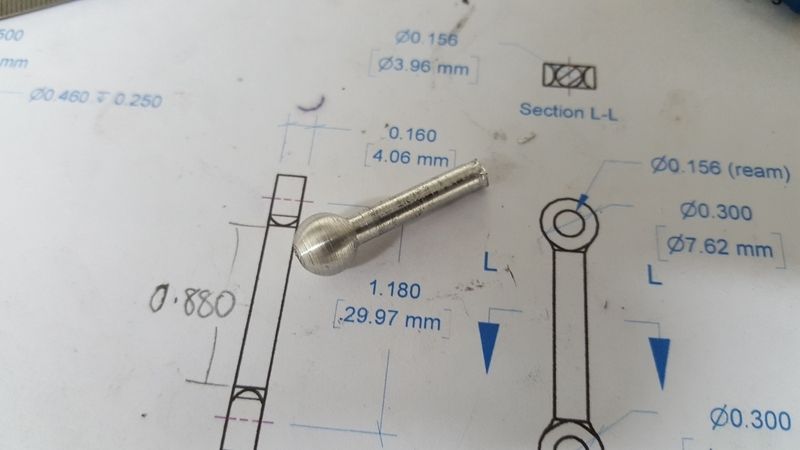

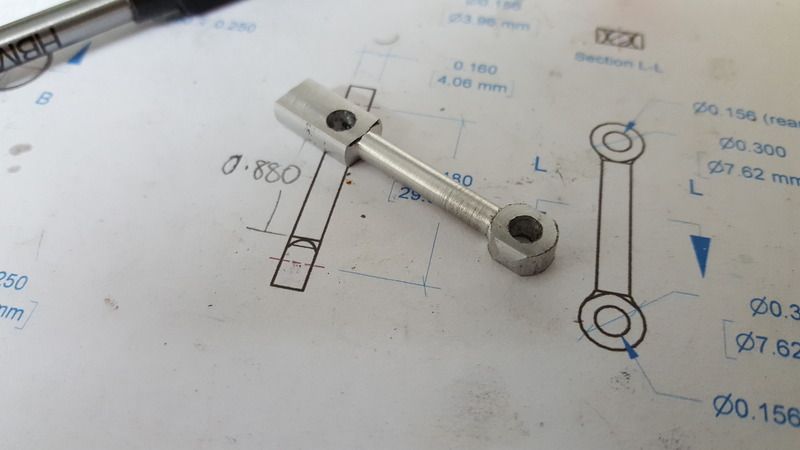

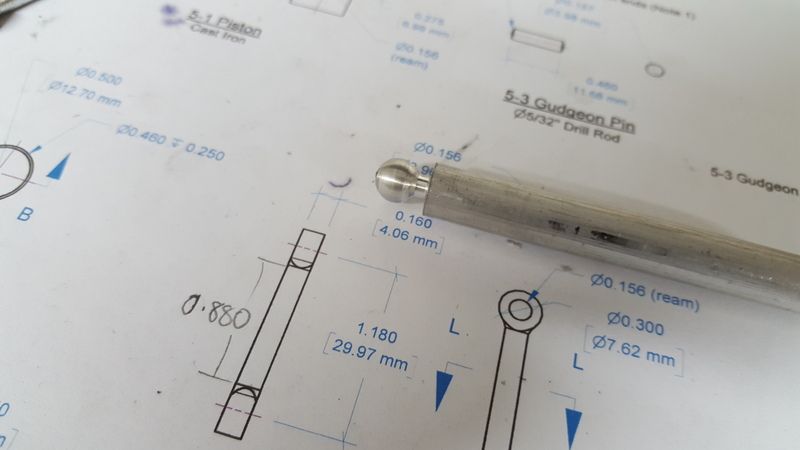

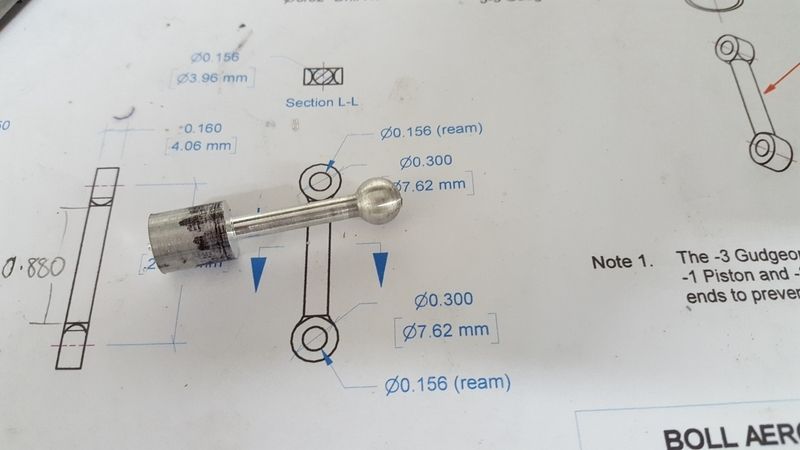

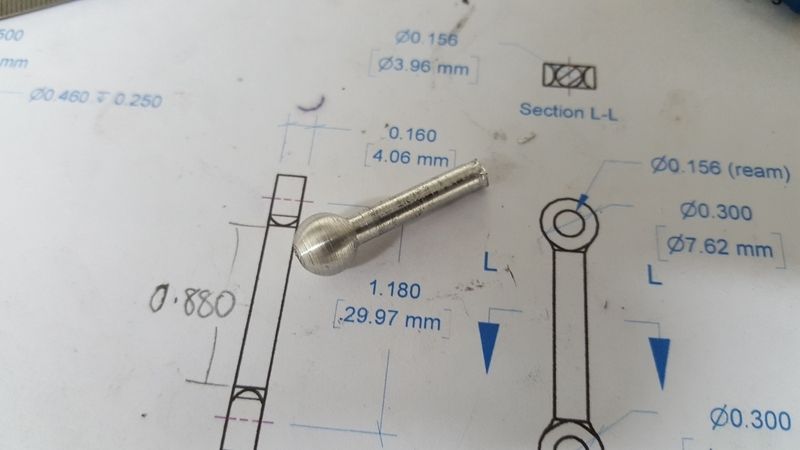

This time I started with a length of aluminium bar and used a radius tool I had made from some scrap flat steel I had to hand. The radius tool turned a reasonably decent looking ball. I then turned the shaft and parted the work piece off with enough material left to turn the ball at the other end. Next I drilled a hole through the centre of another short piece of alloy rod the same diameter as the conrod shaft. I sawed the alloy rod with the hole length wise, then used this to clamp the shaft of the conrod and hold it in the 3 jaw so I could turn the ball at the remaining end. Unfortunately as the final picture shows stress of turning with the radius tool snapped the shaft of the conrod.

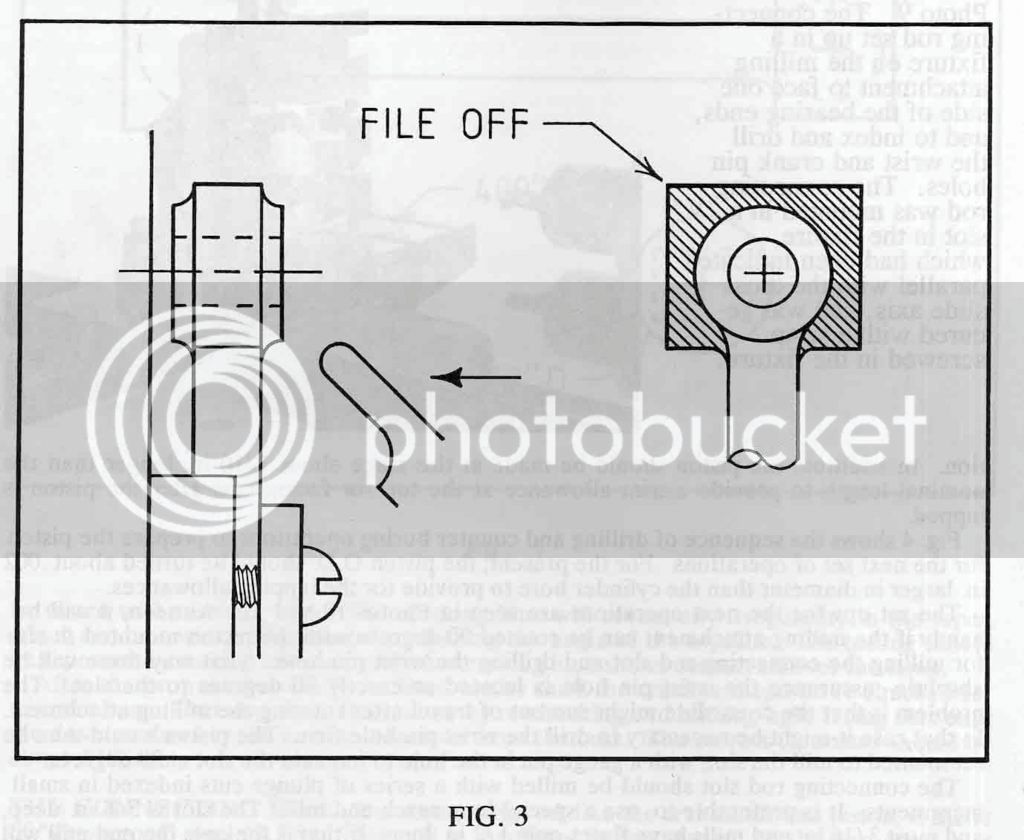

I feel like this approach has merit. There are a couple of things I plan to try next. I will turn the blank to close to finished diameter before any other operations. This will dramatically reduce the amount of material the radius tool needs too remove and therefore the amount of sideways stress placed on the conrod in the final operation. Secondly, I plan to rework the radius tool slightly to remove the width on each side of the radius. The profile is far to square on either side of the half circle. If these were sharper shapes, they would cut more easily and reduce the side loading on the work piece.

Unfortunately it's going to be a few more days before I can get the time to try all this, but having some time to think about it may unlock some more ideas.

I always expected the conrod, piston / contra piston and lapping to be the most difficult aspects of the engine.

Of course if I had a mill and a rotary table this would be so simple... but where's the fun in that

oops! 3 steps back!

oops! 3 steps back!