You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bending Copper tubing??

- Thread starter Jeff02

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

machinist dave

Member

- Joined

- Aug 3, 2008

- Messages

- 19

- Reaction score

- 0

i've been successful with filling the tube with a soft medium. plug both ends and fill with sand. i'v also filled tubes with solder and once its shaped melt it back out.worked every time. good luck

- Joined

- Feb 17, 2008

- Messages

- 2,326

- Reaction score

- 440

Jeff,

The most important tool is a torch. Copper work hardens rapidly and must be annealed well and often. The smaller the radius of the bend, the more times it must be annealed. If you are trying to make small radius bends of less than 3 or 4 times the diameter of the tube, you will have to anneal several times. If you are trying to make very small radius bends, then a rod with a groove turned in it that as only slightly wider than the diameter of the tube and as deep as the tube diameter is one way to keep it from collapsing. It is best if the groove has a round bottom, but I seldom do it. Mostly I just cut with a parting tool. You will still need to anneal the tube. It takes little practice, but you will "feel" the tube start to work harden and know you have to anneal it again.

To anneal, heat the tube to a dull red, and then let it cool. You can dip it in water to cool faster if you are in a hurry, but that has no affect on the annealing. After all the bending is done, the oxides that form on the surface of the copper can be removed by dipping in a pickling solution. Lots of different ideas on what to use for pickling and it has been discussed a lot on this forum. I use a 5 percent sulphuric acid as a personal preference, but lots of others use citric acid or a commercial pickle preparation.

Let us know what size tube and what kind of bend and some of us may be able to be more specific in our recommendations.

Gail in NM,USA

The most important tool is a torch. Copper work hardens rapidly and must be annealed well and often. The smaller the radius of the bend, the more times it must be annealed. If you are trying to make small radius bends of less than 3 or 4 times the diameter of the tube, you will have to anneal several times. If you are trying to make very small radius bends, then a rod with a groove turned in it that as only slightly wider than the diameter of the tube and as deep as the tube diameter is one way to keep it from collapsing. It is best if the groove has a round bottom, but I seldom do it. Mostly I just cut with a parting tool. You will still need to anneal the tube. It takes little practice, but you will "feel" the tube start to work harden and know you have to anneal it again.

To anneal, heat the tube to a dull red, and then let it cool. You can dip it in water to cool faster if you are in a hurry, but that has no affect on the annealing. After all the bending is done, the oxides that form on the surface of the copper can be removed by dipping in a pickling solution. Lots of different ideas on what to use for pickling and it has been discussed a lot on this forum. I use a 5 percent sulphuric acid as a personal preference, but lots of others use citric acid or a commercial pickle preparation.

Let us know what size tube and what kind of bend and some of us may be able to be more specific in our recommendations.

Gail in NM,USA

mklotz

Well-Known Member

One of these...

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=3755

Occasionally my local HF has available a similar miniature version that accepts tubing diameters smaller than 1/4". I couldn't find it on their website but I didn't spend much time looking.

Gail beat me to it but I'll reiterate that annealing is the real key to clean bends.

http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=3755

Occasionally my local HF has available a similar miniature version that accepts tubing diameters smaller than 1/4". I couldn't find it on their website but I didn't spend much time looking.

Gail beat me to it but I'll reiterate that annealing is the real key to clean bends.

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 788

Marv I think you mean this one http://www.harborfreight.com/cpi/ctaf/Displayitem.taf?itemnumber=94571

Tin

Tin

How about one of these:

http://www3.towerhobbies.com/cgi-bin/wti0001p?&I=LXE228&P=SM

I haven't seen one in the flesh,but it looks quite useful

http://www3.towerhobbies.com/cgi-bin/wti0001p?&I=LXE228&P=SM

I haven't seen one in the flesh,but it looks quite useful

- Joined

- Jul 16, 2007

- Messages

- 2,987

- Reaction score

- 1,055

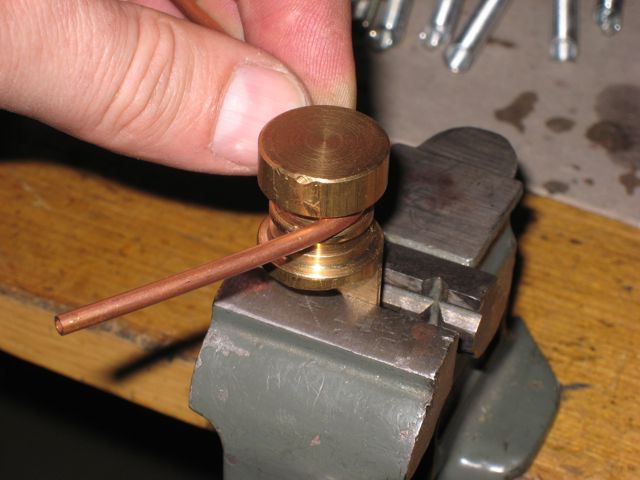

How about this?

gbritnell

http://bbs.homeshopmachinist.net/showthread.php?t=29136&highlight=tubing+bender

gbritnell

http://bbs.homeshopmachinist.net/showthread.php?t=29136&highlight=tubing+bender

mklotz

Well-Known Member

Tin:

Yes, that's the one. I use it more than the big one.

gbritnell:

I remember that thread! Beautiful work. If I bent a lot of tubing, I'd invest the time to build a copy of yours.

Yes, that's the one. I use it more than the big one.

gbritnell:

I remember that thread! Beautiful work. If I bent a lot of tubing, I'd invest the time to build a copy of yours.

deere_x475guy

Well-Known Member

Jeff here is a thread to what I built to bend tubing.

http://www.homemodelenginemachinist.com/index.php?topic=1032.0

http://www.homemodelenginemachinist.com/index.php?topic=1032.0

old-biker-uk

Well-Known Member

- Joined

- Jan 11, 2008

- Messages

- 76

- Reaction score

- 5

That's the way to do it.......tel said:Annealing, patience (lots of it) and fingers.

Of course, nobody can see the pipes once the cladding is on.

Mark

deere_x475guy

Well-Known Member

Your welcome Jeff, I have given credit to the original designer in that thread. McGuyver went all out on the one he built. Mine is just a quick knock off of his very professional looking tool.

Edit:

I just seen gbritnell post and looked at his bender. I think it would be worth a serious look by you also. He did a very nice job on that bender and it looks like it will do anything the one I built will do unless I am missing something.

Nice job gbritnell.

Edit:

I just seen gbritnell post and looked at his bender. I think it would be worth a serious look by you also. He did a very nice job on that bender and it looks like it will do anything the one I built will do unless I am missing something.

Nice job gbritnell.

J

johnthomp

Guest

i dunno abbout anyone else but my preffered method of bending any tubeing is to anneale the hell out of it then plug one end fill the tube with a 50 50 solution of fairy liquid and water then freeze it overnight the mixture will solidify but be elastic enough not to crush in the tube when bending but not brittle enough to rip the sidewall when bending and the beauty of the fairy ice is it melts out verry cleanly and quick

now even hands that do pipeing can feel soft as your face with mild green fairy liquid

now even hands that do pipeing can feel soft as your face with mild green fairy liquid

Similar threads

- Replies

- 15

- Views

- 1K

- Replies

- 15

- Views

- 1K