maverick

Well-Known Member

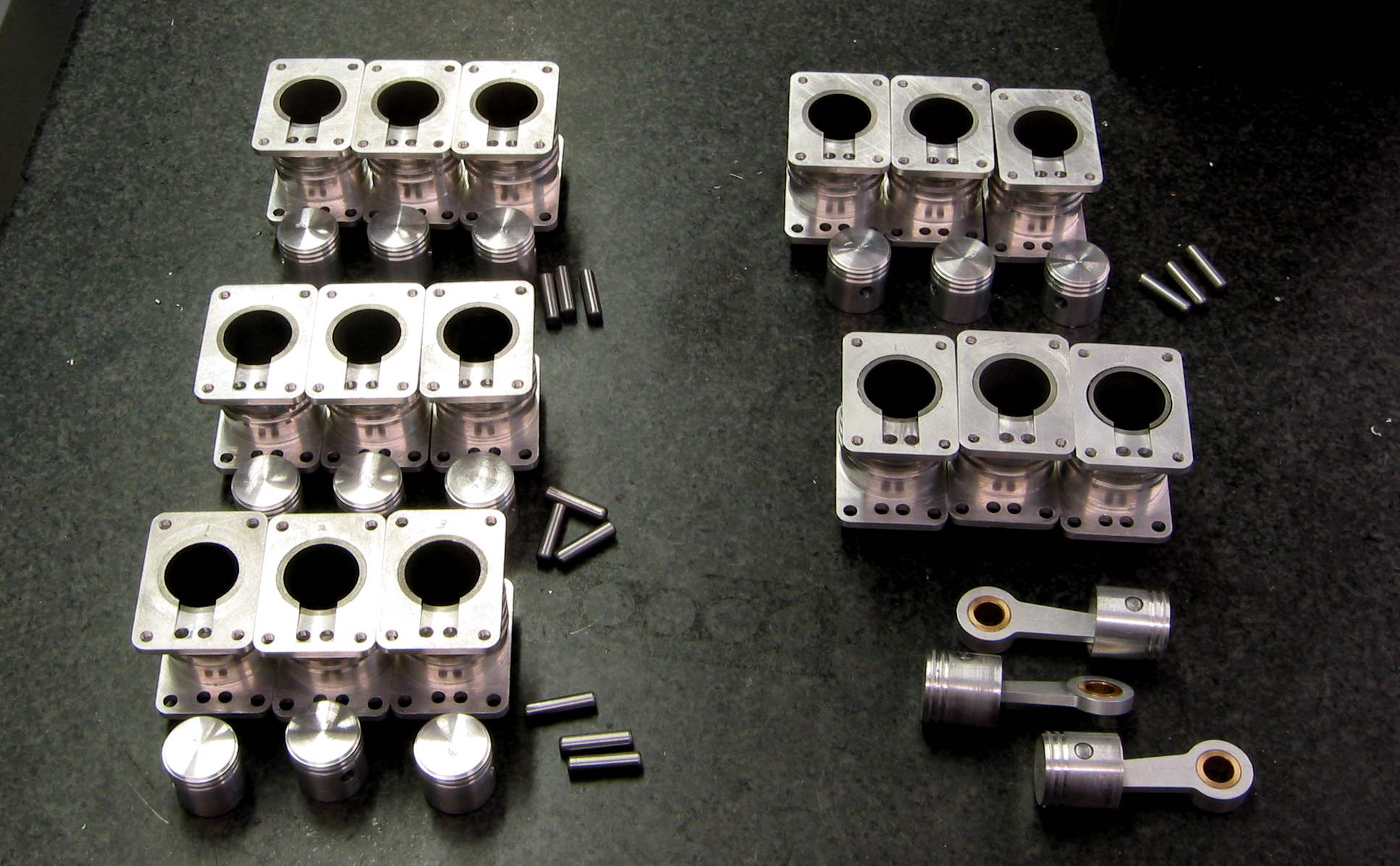

Chris, That sound OK to me. I have extras of conrods and collets and have 12 flywheel blanks, although

1 or 2 may turn into setup pieces. I will be away from the shop till sunday but will try to check in.

Mike

1 or 2 may turn into setup pieces. I will be away from the shop till sunday but will try to check in.

Mike