- Joined

- Nov 14, 2009

- Messages

- 675

- Reaction score

- 104

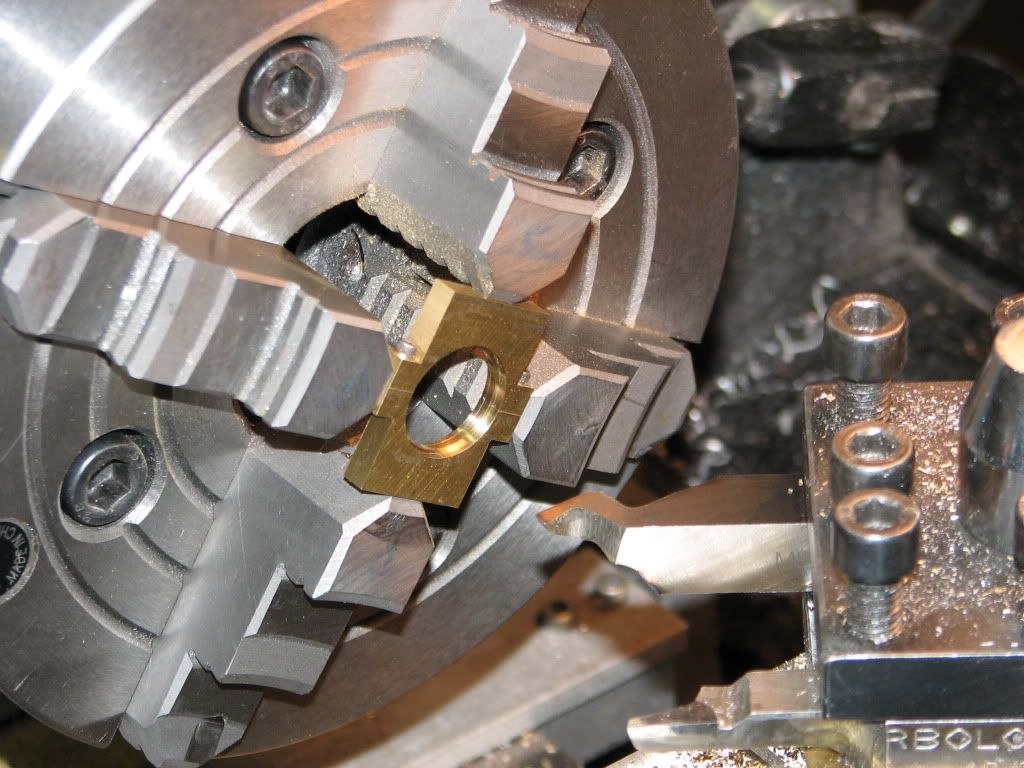

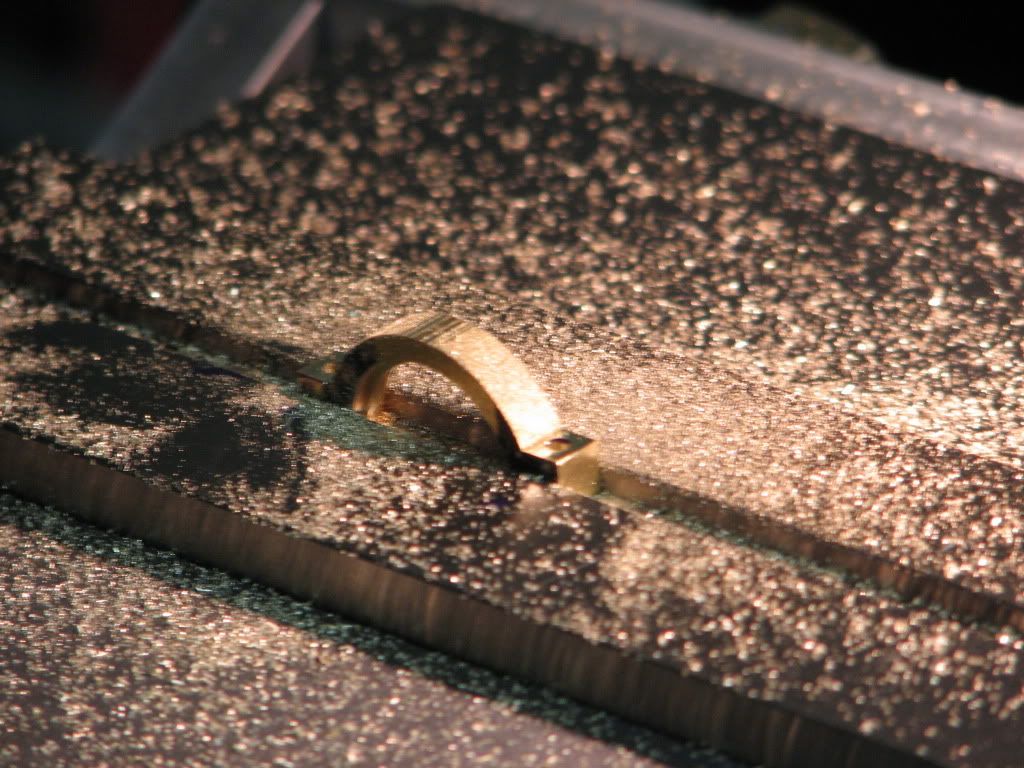

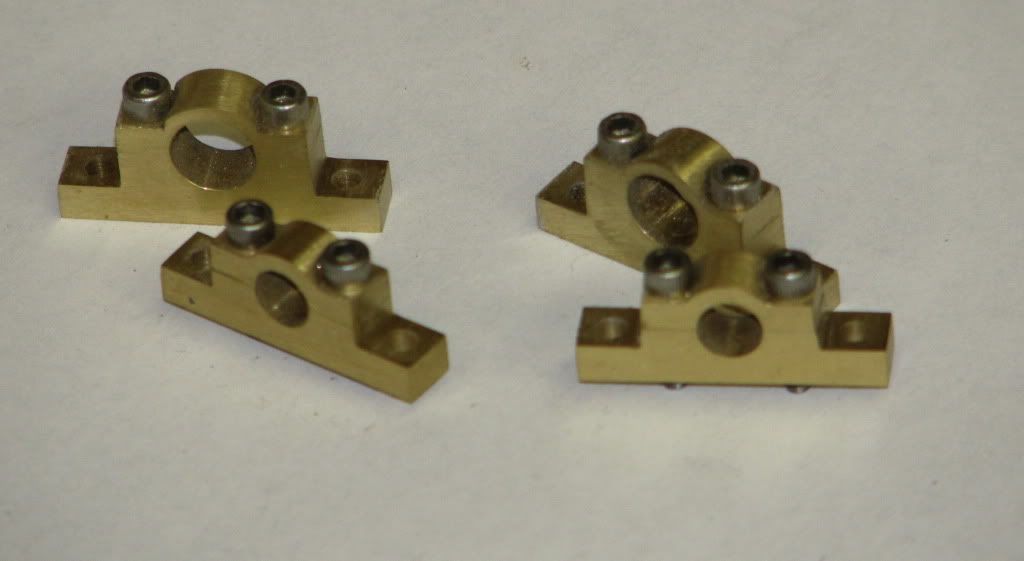

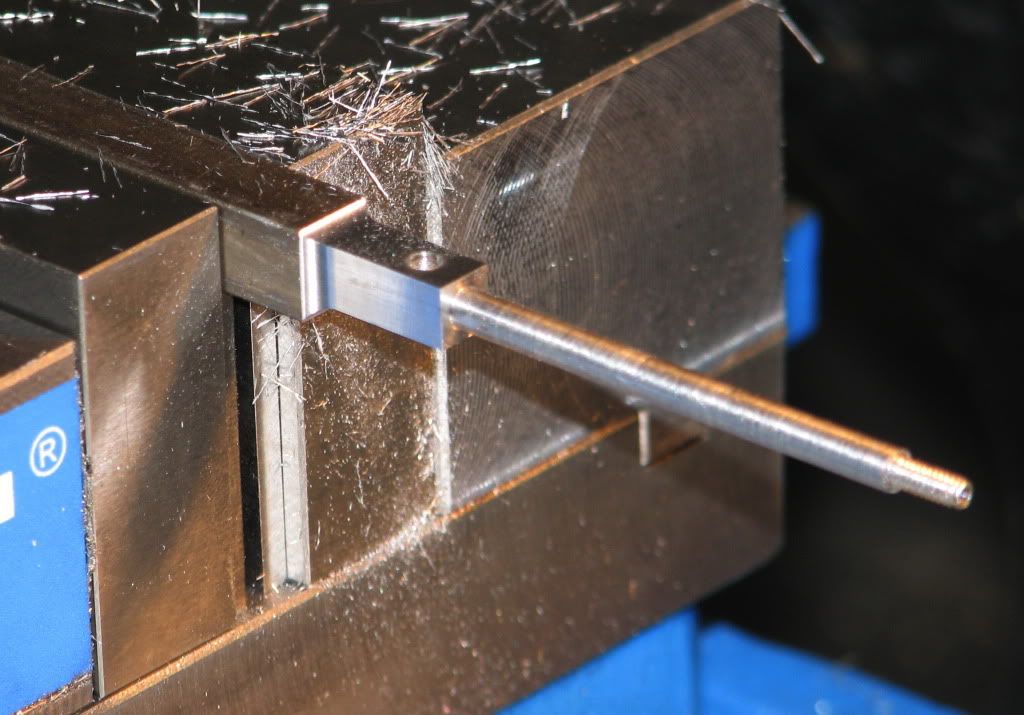

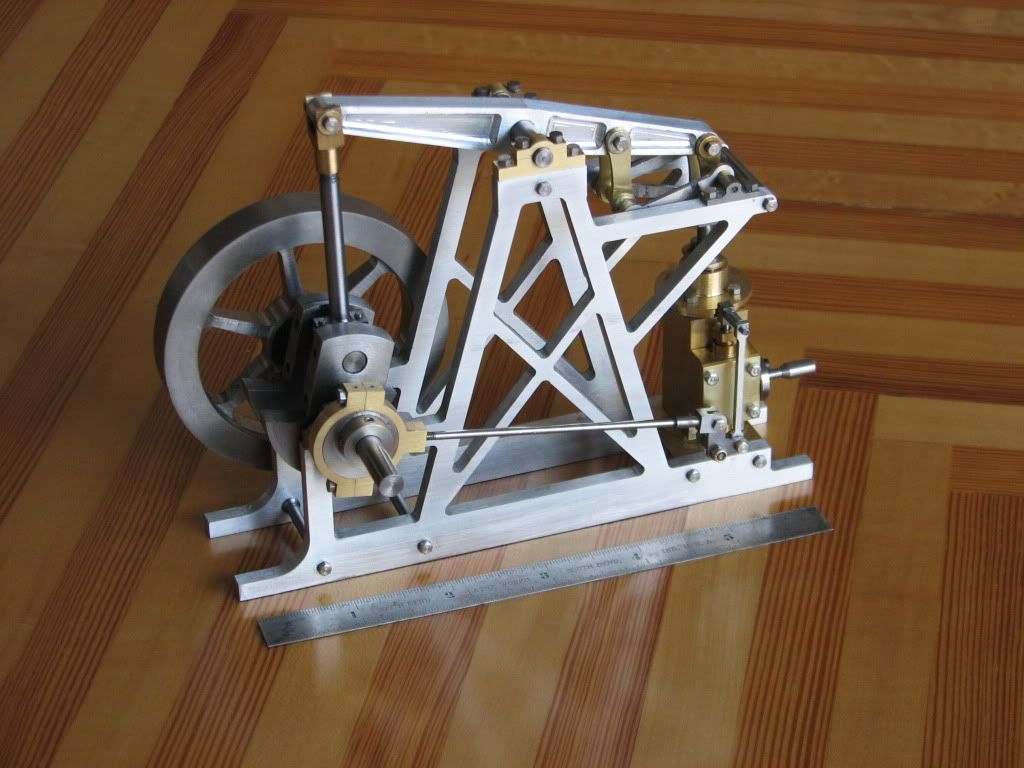

Hi,this is looking good Tux,I built my crankshaft up,locktiteing the shafts to the webs and setting them in a pair of matching v-blocks till set then pinning,came out ok,I didn't fancy silversoldering as i try to keep away from heating things up if possible.

Don

Don