I came up with a totally new carburetor design. This one is extremely simple and easy to build. I kind of went out of the box on a few of the features, but they seem to work well. I've tried the carburetor out on my plumbing parts engine and so far I'm very pleased with the results. It idles down nicely and will rev up to nice high RPM (well, high for this engine).

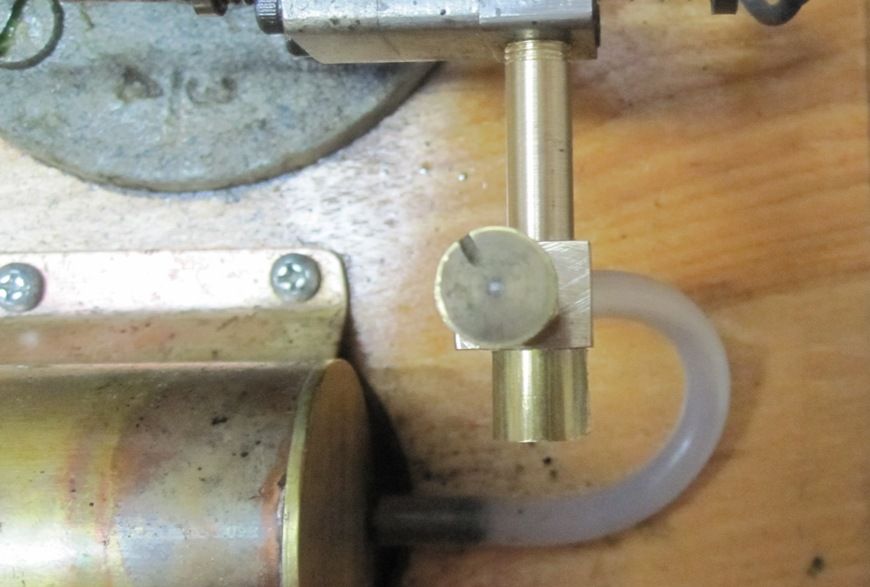

In this first picture, you can see the throttle adjustment. It is nothing more than a 5/16" ID split sleeve that rotates on the boss on the back of the carburetor body. The hole drilled into the side is the air inlet hole.

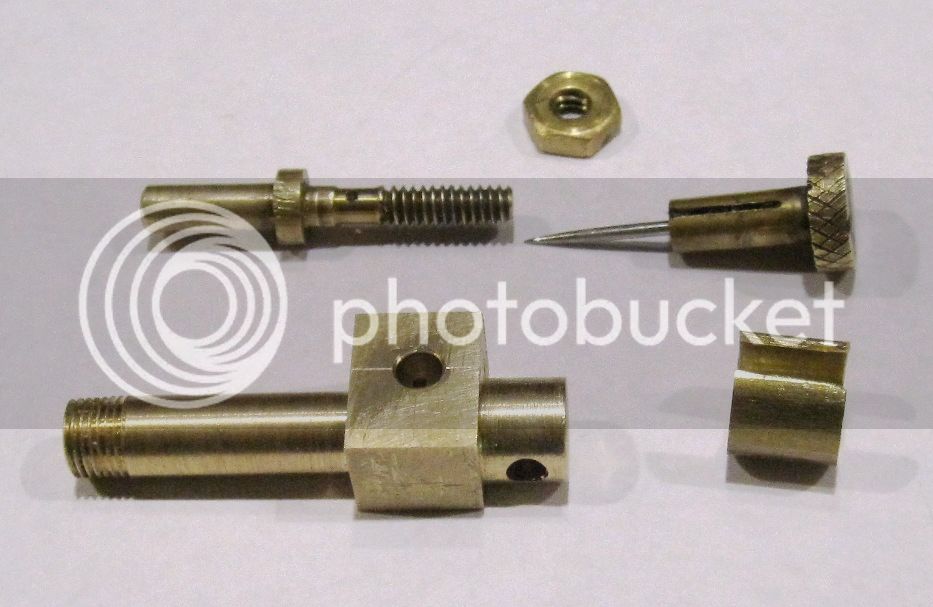

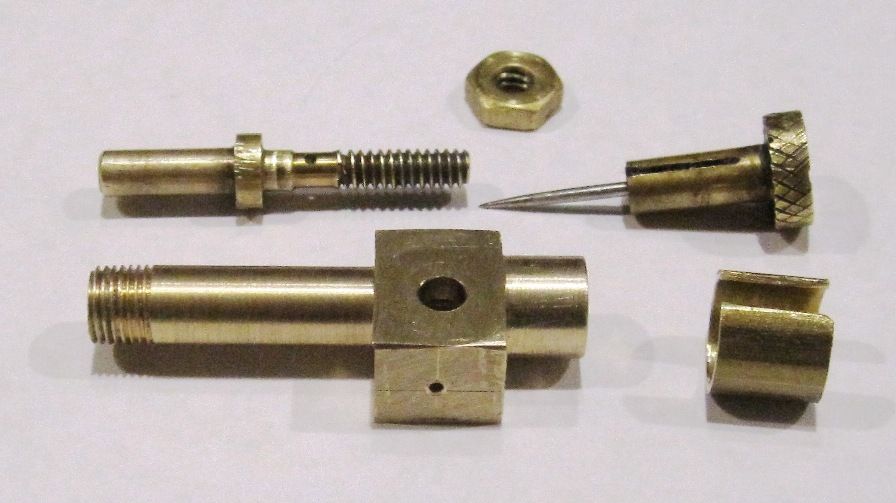

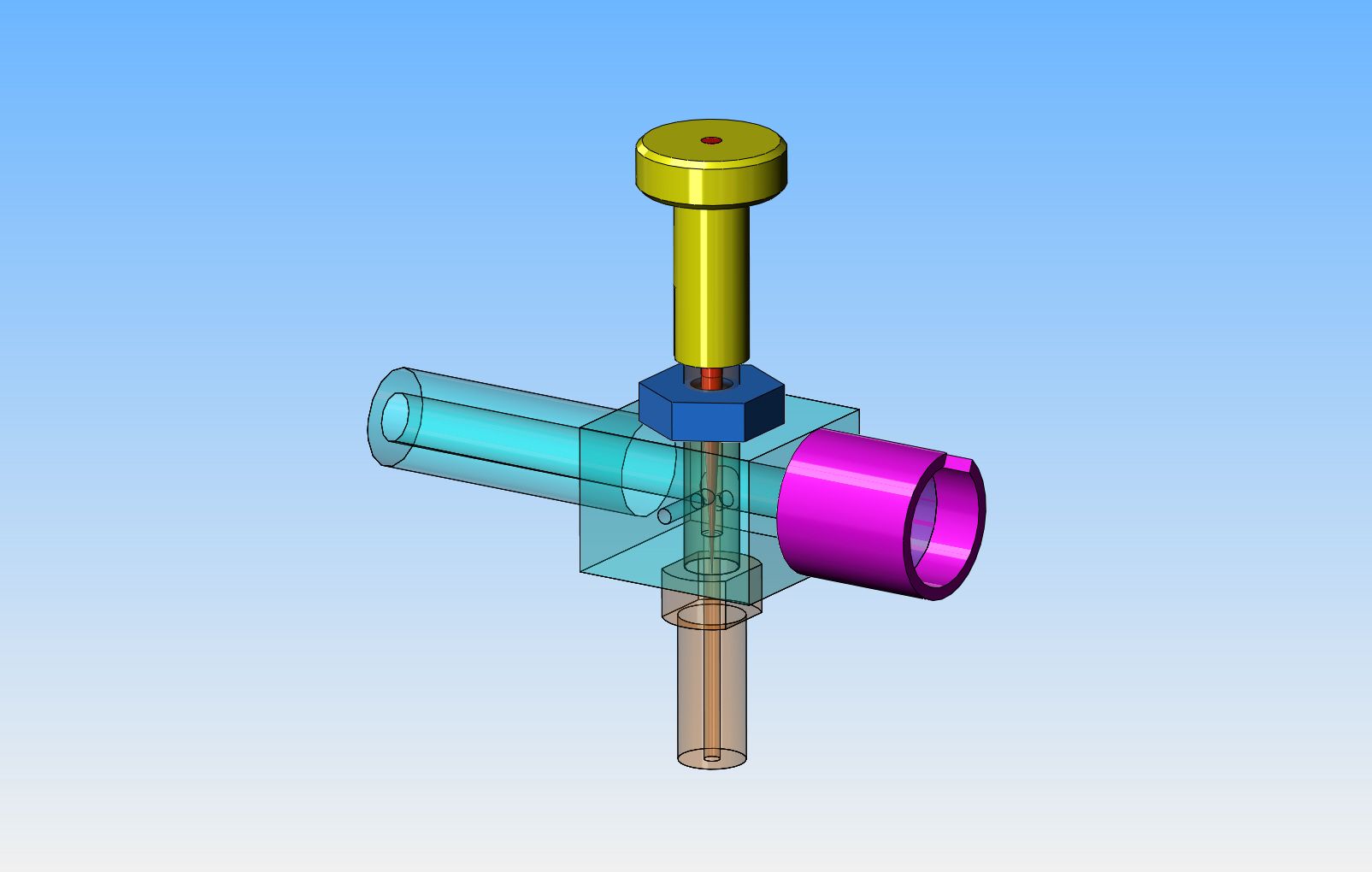

In his next picture, you can see the air bleed or premix hole. It is drilled all the way through to the center of the mixer tube just below the exit orifice that admits fuel into venturie. The entire mixer tube can be rotated left or right slightly to offset the holes in the body and tube, adjusting the amount of air that gets admitted. Different, I know, but it works well and probably won't have to be adjusted very often if at all, once tuned.

Here's a shot from the top. You can see that the mixer tube is an interference fit with the main air inlet. It protrudes slightly into the main air chamber and forms a venture. The fuel orifice is opposite and slightly above the premix or air bleed hole and faces into the air passage at a 90 degree angle.

Here is a video of the carburetor in operation on my plumbing parts engine.

[ame]http://www.youtube.com/watch?v=UaY9ROZRUqE[/ame]

I do have drawings for this but need to make some improvements to the throttle adjustment mechanism.

Chuck