I've now built and tried 4 different variations of carburetors on this engine and am not really pleased with any of the results. The engine would run on all the carbs, but ran rough and wouldn't idle the way I wanted. I've decided to revisit some of the other parts of the engine as I think that's where some of my problems are. Most notable is the valve timing. I've always had a pretty simplistic view of cams and valve timing, figuring the intake and exhaust lobes should be 90 degrees apart, that the intake should open at top dead center and close at bottom center and the exhaust valve should open at or shortly before bottom dead center and close at or before top dead center. Well, folks, turns out it isn't quite that simple.

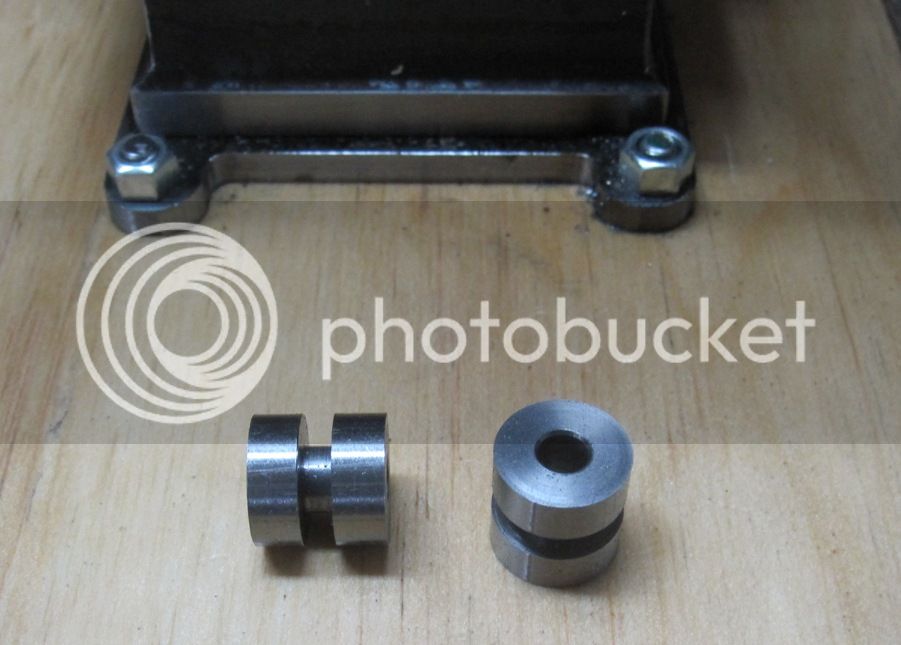

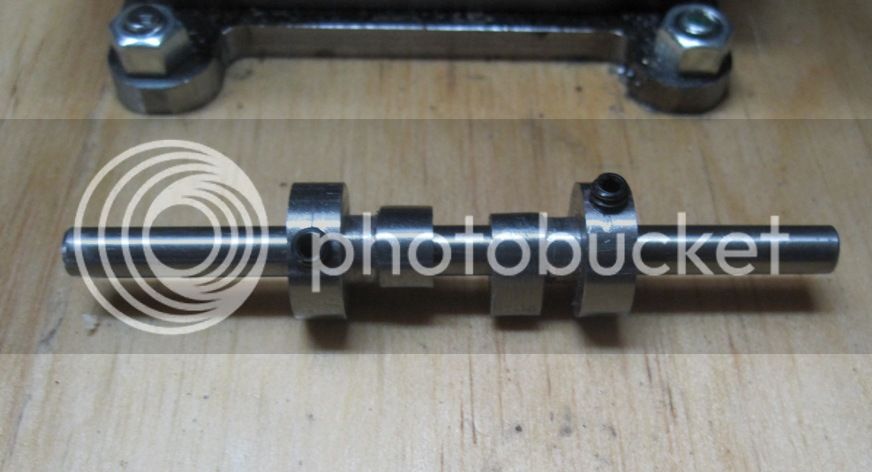

I found an article on valve timing and a series of 4 articles on cam grinding and design in my collection of Model Engine Builder. By the way, if you haven't looked through your issues of the magazine for a while, it's definitely worth revisiting. I've learned that articles in magazines don't generally coincide with what I'm working on at the moment and tend to get overlooked. It's amazing how many times I go back to older issues of magazines and find articles I had completely forgotten about or didn't even know I had. Anyway, the cam lobes should be separated by something closer to 105 degrees than 90 degrees. The intake should open from 10-25 degrees BTDC and close 40-60 ABDC. Think I'll choose 15 and 50, respectively. The exhaust valve should open from 40-60 BBDC and close 5-25 degrees BTDC. The overlap, when both valves are open, should be in the range of 10-40 degrees. A shorter overlap improves slow speed running, so I'm thinking 20 degree overlap should be good. I'm going to make the intake and exhaust lobes separately so I can adjust them independently.

By the way, I got the engine to run on Propane using two of my carburetor designs. I just removed the burner tip from my propane torch and connected it to the carburetor with a urethane tube. I had to fiddle with the propane torch control valve and the carb mixer, but I got the engine to run at least as well as it did on liquid fuel. Turns out you really don't need a demand valve as long as you don't leave the engine running unattended. But for now, the carb experiments are on hold until I get the valve timing and cam design sorted.

Chuck