- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

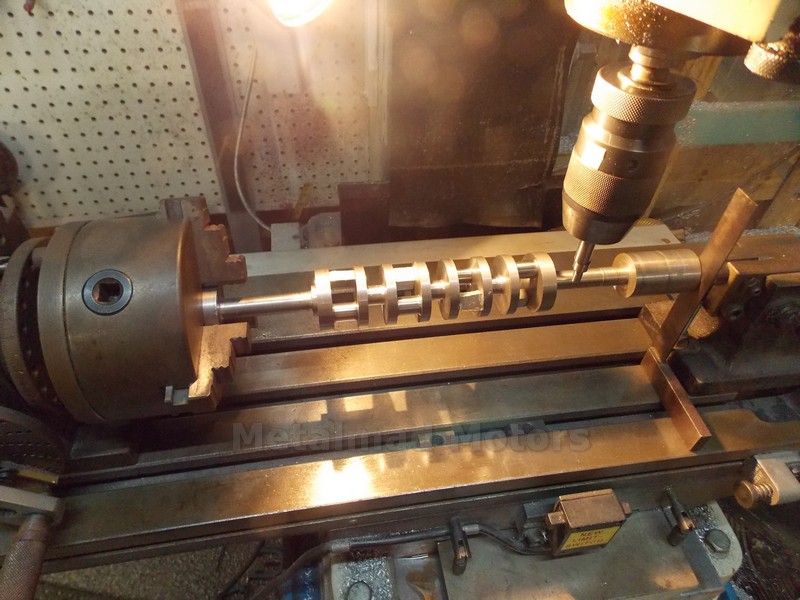

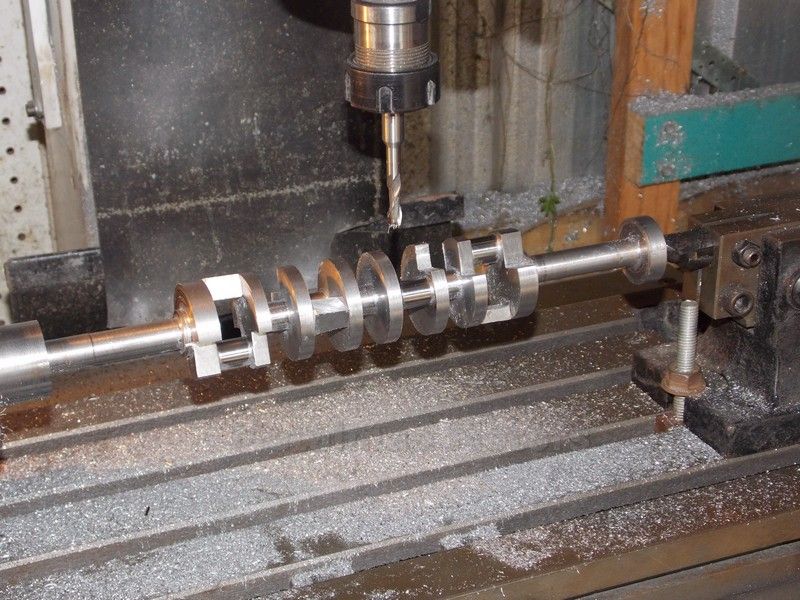

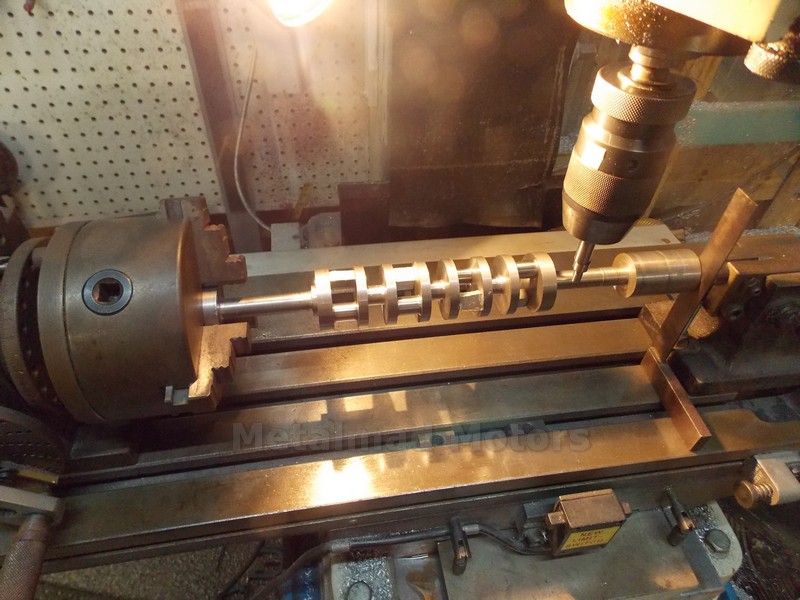

Im hoping to get the webs milled tomorrow then i'll rest the crank for a few days before taking the main journals down to size ETC ETC.

Pete

PS

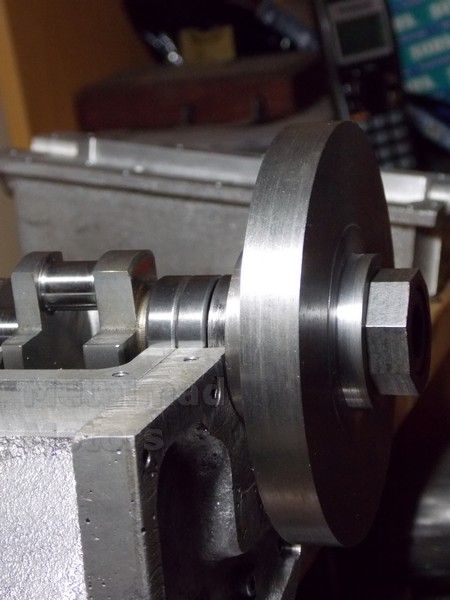

Here is a pic I forgot of the center hole setup, sorry guys

Notice the flat side of the bar that is clamped to the angle plate in order to get the holes all the same.

This length of Bar stock is almost 13 inches long and I used a machinist square to line it up before clamping and then used a wobbler to find the bar center.

Pete

PS

Here is a pic I forgot of the center hole setup, sorry guys

Notice the flat side of the bar that is clamped to the angle plate in order to get the holes all the same.

This length of Bar stock is almost 13 inches long and I used a machinist square to line it up before clamping and then used a wobbler to find the bar center.