- Joined

- Nov 12, 2009

- Messages

- 1,427

- Reaction score

- 221

Hi guys I guess its time I started another build log :hDe:

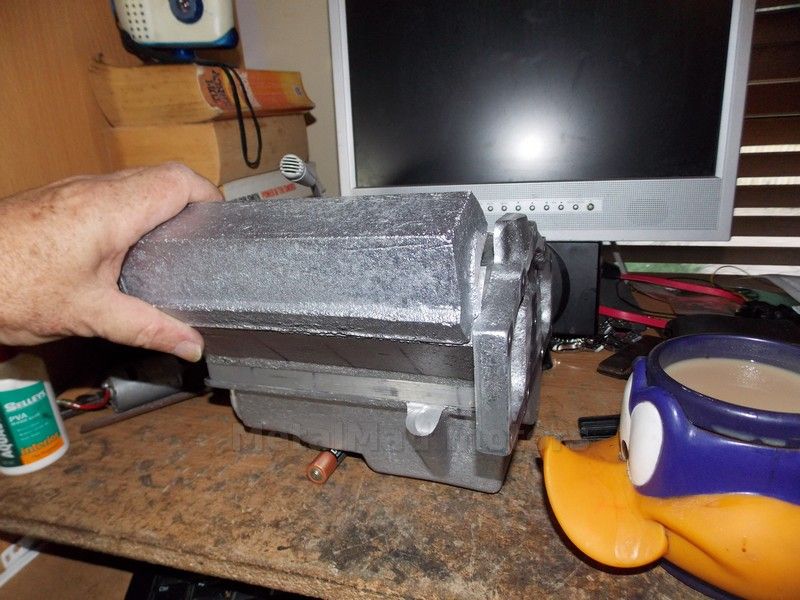

Some time ago someone out there in cyber space sent me an incompleate set of plans for a Chev inspired V8 and I thought I have a go at Casting up the Block.

My Mate down the road drew me up a block in CAD (Ausdier) and this is the start of the journey.

I dont know if I will ever finish it as lots of dims are unreadable or missing, but so far, im loving making the Castings. After id made up the pattens for the block Ausdier came over for the first pour, unfortunetly I know very little about Casting and had a few issues. :fan:

I did not make the sand anywhere near wet enougth and put the spew hole much too close to the flasks (edge of box) As a resault the top box lifted and I lost half an inch or so of my pour onto the dirt.

I gave another Mate, Bez a call that night and he suggested turning the pour around so the magority of metal is in the bottom flask and using lots of weight or clamping the flasks together.

So far this build is mostly about learning to cast my own Engines.

Pete

Some time ago someone out there in cyber space sent me an incompleate set of plans for a Chev inspired V8 and I thought I have a go at Casting up the Block.

My Mate down the road drew me up a block in CAD (Ausdier) and this is the start of the journey.

I dont know if I will ever finish it as lots of dims are unreadable or missing, but so far, im loving making the Castings. After id made up the pattens for the block Ausdier came over for the first pour, unfortunetly I know very little about Casting and had a few issues. :fan:

I did not make the sand anywhere near wet enougth and put the spew hole much too close to the flasks (edge of box) As a resault the top box lifted and I lost half an inch or so of my pour onto the dirt.

I gave another Mate, Bez a call that night and he suggested turning the pour around so the magority of metal is in the bottom flask and using lots of weight or clamping the flasks together.

So far this build is mostly about learning to cast my own Engines.

Pete