[SIZE=+2]

THE CYLINDER ASSEMBLY - 2. Making all the Bolts[/SIZE]

INTRODUCTION

In my previous post I referred to making the set of bolts for the two cylinders as an "irksome chore". This is perhaps a bit unfair in the sense that it becomes so because there are 40 of the darn things and not because the steps required for each bolt are boring. It would be equally or even more irksome to make 40 cylinders or 40 flywheels! So on reflection I think that the process of converting over 70cm of 5mm steel bar into 40 M2 bolts may hold some interest for some members and so will report it in this post like any other step in the build of my engine.

DESIGN CONSIDERATIONS

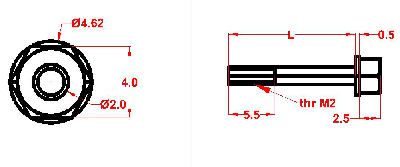

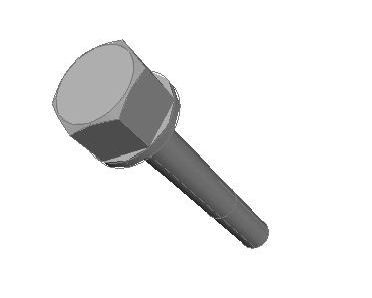

For both asthetic and practical reasons these 40 screws are identical except for a single parameter namely the length of the shank (L) as shown in the drawing extracts below.

So the bolts are all have 2mm diameter shanks threaded for a length of 5.5mm of which only 4mm of thread are intended to enter into the corresponding threaded hole. The bolts all have the same head which is a hexagon with 4mm across the flats (F) and with a circular base, height 0.5mm, of diameter 4.62mm (V) which is the distance between opposite vertices of the hexagon obtained from the formula V = F / cos(30).

The 20 bolts required for each of the two Cylinder Assemblies are listed below:

- 6 bolts with L = 7mm for fixing the Cylinder Top Cover to the Cylinder Unit.

- 5 bolts with L = 10mm and 1 bolt with L = 15mm for fixing the Cylinder Bottom Cover and the Cylinder Unit itself to the Vertical Structure.

- 8 bolts with L = 19mm for fixing the Steam Chest Cover and the Steam Chest to the Cyinder Unit.

BUILD APPROACH

The bolts were machined from a 5mm diameter bar of mild steel. I was not able to discover the composition of this steel but judging from the way it behaved during machining I would guess that is lead free and with a carbon content of around 0.3%.

The process I use to make nuts and bolts is of course influenced by the tools I have. If I were making a single bolt then the basic sequence of steps I would use for making it would be more or less to make the shank, prepare a cylinder for the head, cut the bolt off the bar and then hold the bolt by the shank to make its head.

Here is this process described in more detail.

- Make the shank and prepare the cylinder for the head

- Hold the raw bar in the chuck with about L + 6 mm protruding from the jaws.

- Use a knife tool to face off the end.

- Use a knife tool to turn the first 7mm of the shank to the final diameter of about 0.02 mm under 2mm.

- Thread the first 5.5mm of the shank holding the M2 die in some sort of tailstock die guide.

- For bolts with shanks longer than 7 mm, use a knife tool to complete turning the shanks in one or two sections not longer that 6mm. This is necessary to avoid excessive flexing of the rather thin shank even when the tool is sharp.

- Use the knife tool to turn to a diameter of 4.62 mm a cylinder 4.5mm long for the head.

- Manually cut the screw off the bar leaving the head section with a length of at least 3.5mm.

- Make the head

- Gently hold the bolt in the 3-jaw by the shank with the head cylinder pressed up against the jaws.

- Face off the end so that the head has the required finished length of 3mm.

- Make the flats of the hexagon with a hand file, using my File Guide [thread]19573[/thread]and using the lathe's Gear Train to position the angle of the lathe spindle.

- Use a metric threading tool to turn the 30 degree bevel on the edge at the end of the head.

So, on this basis, what is a good process for making 40 bolts? I had to choose between two alternatives.

- Make the bolts one by one, doing for each the above process. With this option I would do a lot of setting up and measuring to ensure that all the bolts turn out with the correct dimensions.

- Do each setup once only and for each apply the corresponding step of the process to all 40 bolts. With this option I would do a lot of bolt mounting and dismounting but, with proper use of a carriage stop, I would do the setting up and most of the measuring only once.

I plumped for the second approach. So I applied each of the following four steps to all 40 bolts.

- For each bolt, make the shank, prepare the head cylinder, cut the bolt off the bar. During this process the Knife tool was sharpened after every three bolts.

- For each bolt, face off the end of the head using the carriage stop to ensure that all heads have the same length.

- For each bolt file the flats of the hexagon section of the head, again using the carriage stop to ensure that the circular bases all have the same length.

- For all bolts machine the 30 degree bevel again using the carriage stop to ensure that all bevels have the same depth.

There was a problem in this approach owing to the fact that my 3-jaw self centering chuck cannot grip diameters below 3mm and so cannot grip the 2mm shanks of the bolts. To make a single bolt I would solve this problem simply by holding a smaller chuck in the 3-jaw. But this is inappropriate when using the same setup for many bolts because the teeth of this smaller chuck dont close in a plane orthogonal to the axis; when closing the chuck, its teeth move foreward along the axis as well as closing towards the axis. This would have made the use of the carriage stop inaccurate for the last three steps of the process. So I solved the problem by making a small mild steel split sleeve which has a 2mm bore, a 3.4mm external diameter and is 5mm long. The big chuck squeezes the sleeve which in turn squeezes the bolt shank. It is important that the external diameter of the sleeve is a good bit less that the diameter of the head base, and so I could still press the head bases up against the chuck jaws to ensure the correct position of the bolt along the lathe axis. It worked fine.

BUILD LOG

This is the carriage stop which came with the lathe when I bought it and is worth it's weight in gold! Some day I'm going to make a second one to use on the other side of the carriage for when I'm machining rightwards towards a shoulder.

Step 1: Shank and Head Cylinder

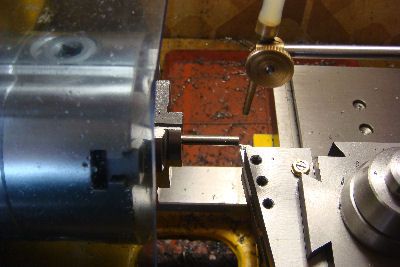

Here is a bit of 5mm raw bar sticking out of the chuck ready to make a bolt with a 19mm shank.

Here is the first 7mm of shank turned to a diameter of 1.98mm.

Here is this first 7mm of shank being threaded M2 with a tailstock guide for the die.

Here is this first 7mm of shank with about 5,5mm of M2 thread.

Here is the bolt with a further 6mm of shank and then with the completed shank with a total length of 19mm.

Here are all 40 bolts at the end of this first step.

Step 2: Face Off the Head

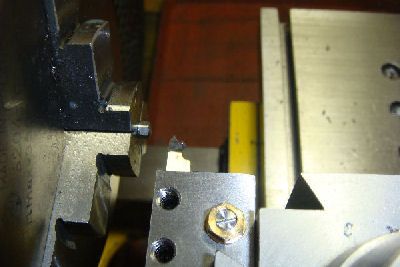

The next three photos show the small sleeve with a 7mm bolt next to it, the bolt inserted into the sleeve and finally the bolt held in chuck via the sleeve.

Here are all 40 bolts at the end of the second step ie with the heads faced off to the final length of 3mm.

Step 3: File the Hexagon Section of the Head

The next two photos show the setup with the Filing Guide for filing the flats of the hexagon sections of the heads and the way I use the lathe's gear train to index the angular position of the spindle. The train is set up to multiply by 4 and the final white gear in the train has 60 teeth. Hence for each full revolution of the lathe spindle 240 teeth pass the horizontal indexing rod held uin the block of wood. So to rotate the spindle by one sixth of a rotation I must let 40 teeth go past the index rod. With the help of the pencil marks at every tenth tooth of the gear it's a piece of cake!

Note that the carriage stop is in position to ensure that the limit to leftwise horizontal motion of the file is always at the same distance from the chuck jaws.

Here is a single bolt with the hexagonal section of its head filed.

Here are all 40 bolts at the end of the third step ie with the heads faced off to the final length.

Step 4: Bevel the Edge of the Head Section of the Head

This photo shows the setup for beveling the Egge of he Hex Section. The carriage stop is in position to ensure that the limit to leftwise motion of the tool is always at the same distance from the chuck jaws.

And here finally are all 40 bolts finally finished.

Total shop time for the job was roughly 20 hours: an average of 30 minutes per bolt. Something tells me that there must be a quicker way!

WHAT'S NEXT?

Now I can start of the two Cylinder Units. After all my recent handling of steel I'm looking foreward to machining brass.