- Joined

- Jan 30, 2011

- Messages

- 365

- Reaction score

- 72

This is difficult :-[.

It really is very nice of all of you to say such nice things and perhaps a mite rather embarassing particularly as I'm very new on the block round here.

I can only say - I just love making models and have done so for most of my 67 years and do love to share the outcome with anyone that is interested. Model making in various forms and interests throughout those years has always figured high on the priority list despite having a varied career - and one which model making has certainly 'interfered' with at times. I guess it would be fair to say that apart from my long suffering but totally supportive wife Sue it is my overiding passion on a day to day basis.

Before being able to be part of something like this on the ME forum and recently on here it was very much a case of the odd occasion on a 'Bit's and Pieces' night whilst a member of the NDSME and laterly once a year at the Forncett Steam Museum's Model Engineers Day Out. I've always believed, that as a member of any group, you will only get out what you are prepared to put in. Forgive the patently obvious but on here it can be done daily and the contact for all concerned is such an asset to our individual take on the hobby.

I really don't see myself as anything other than someone who enjoy's his modelling and am well aware of it's limitations. When I see the work of others on here and elsewhere I can only marvel at their ingenuity, their dedication to the task and their abilities. It is all relative between each and every one of us but all to a common cause.

Over many years, no doubt like so many of us, I have seen some truly stunning models at exhibitions. I have always tried to allow that to influence my thinking - not always on a try to do likewise and certainly not to try to 'out do' but to just try to do the best I can and improve a little each time. Perfection, like beauty, is definitely in the eye of the beholder. It's how you use it that's down to the individual.

Hope you can see where I'm coming from and that you won't see that as anything other than sincere

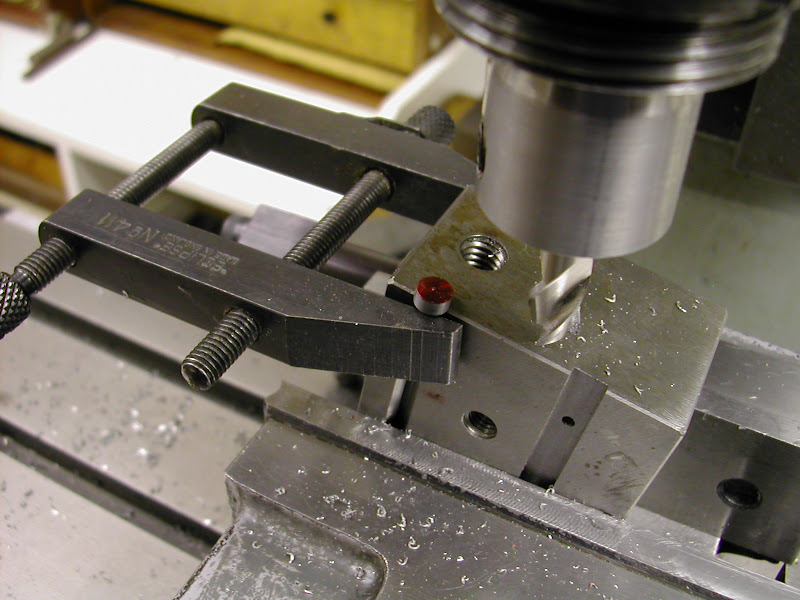

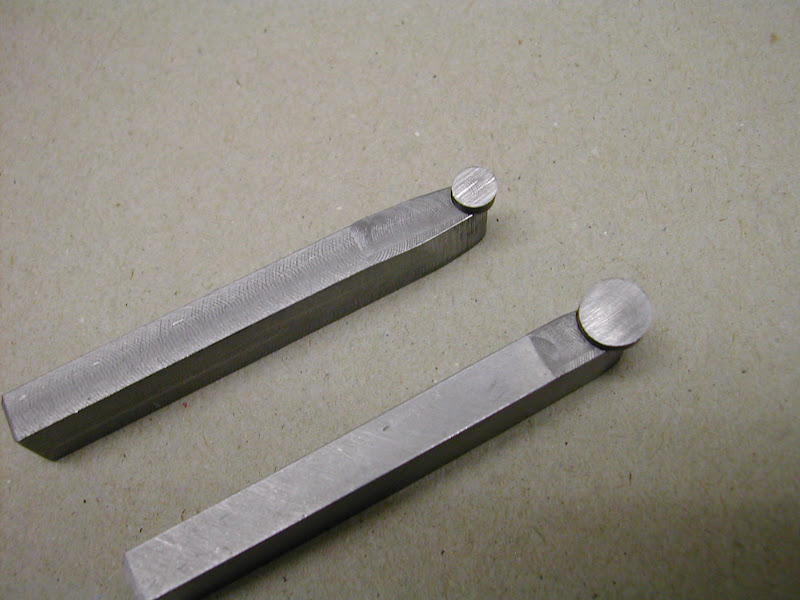

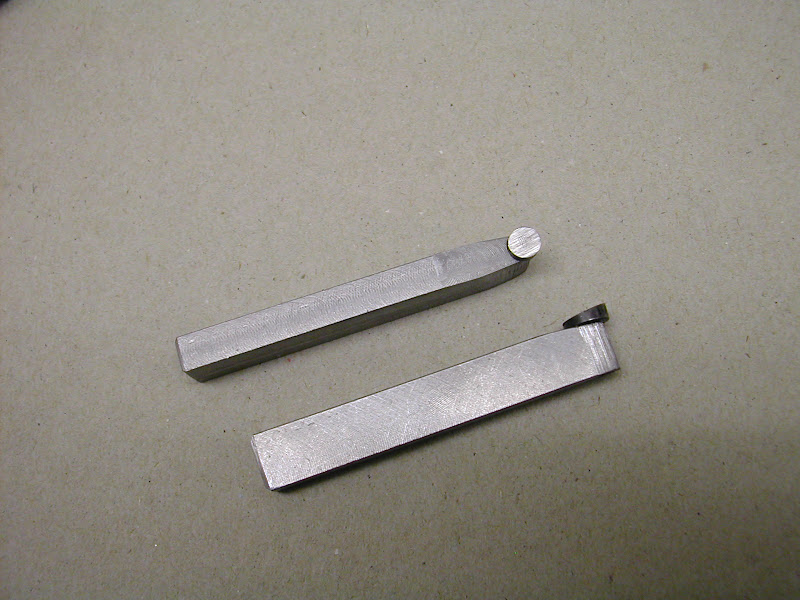

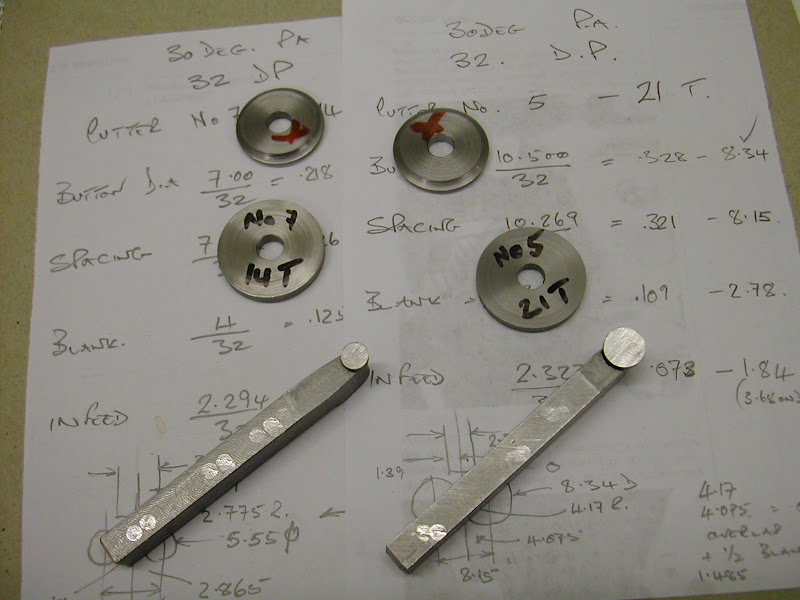

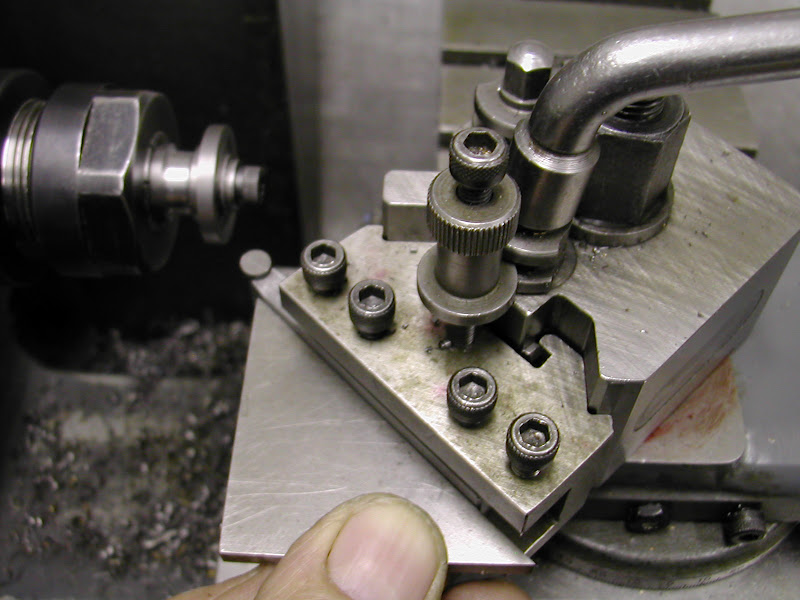

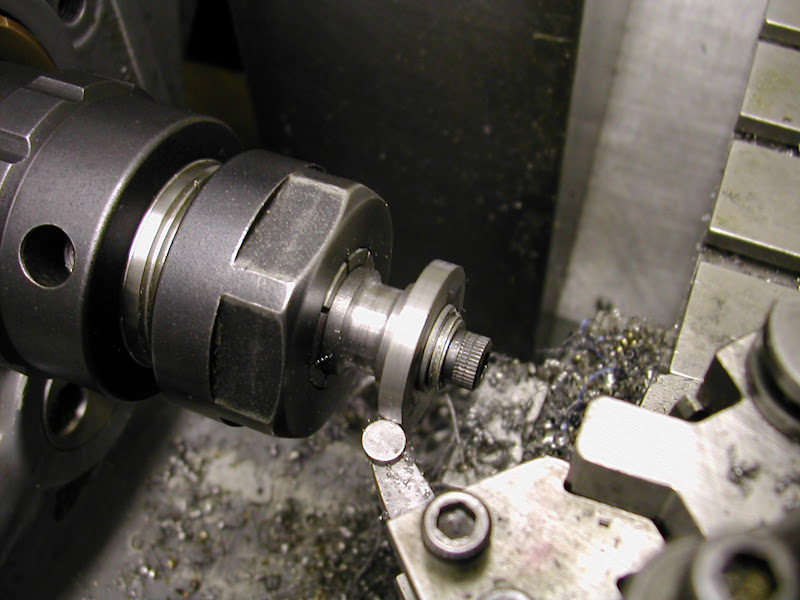

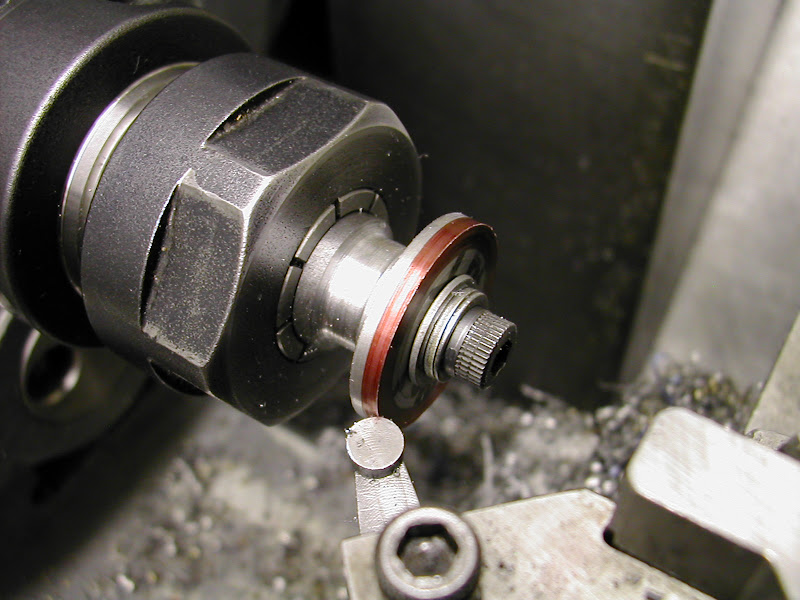

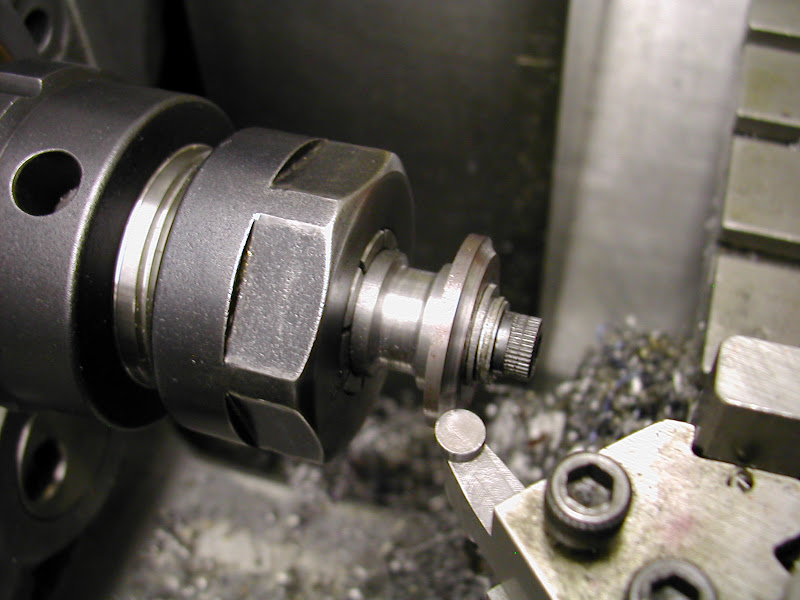

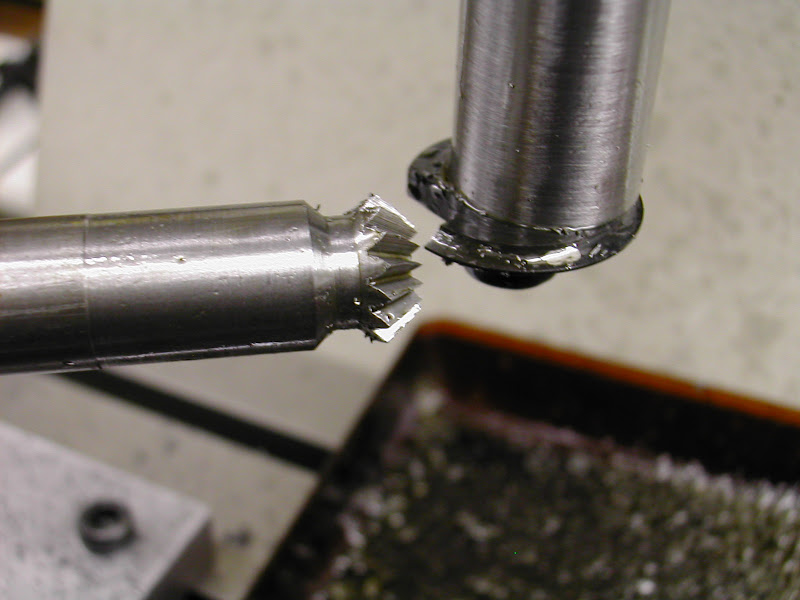

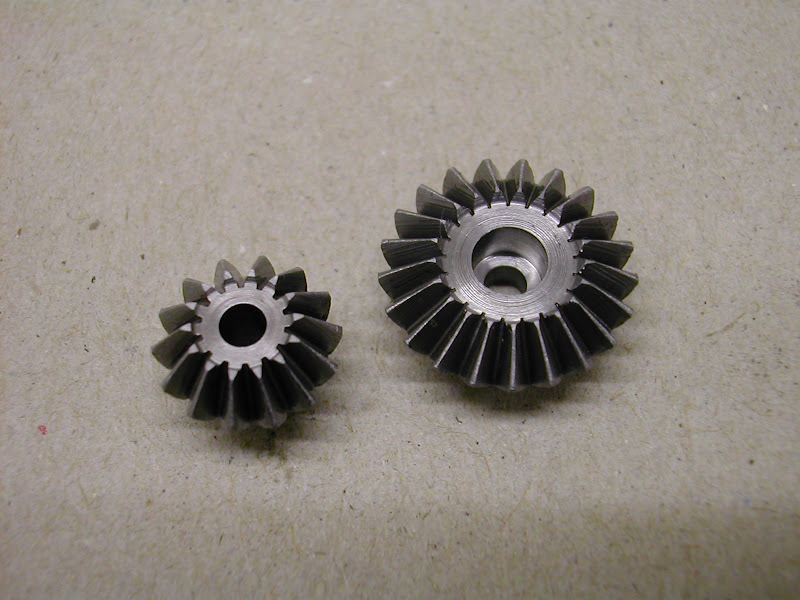

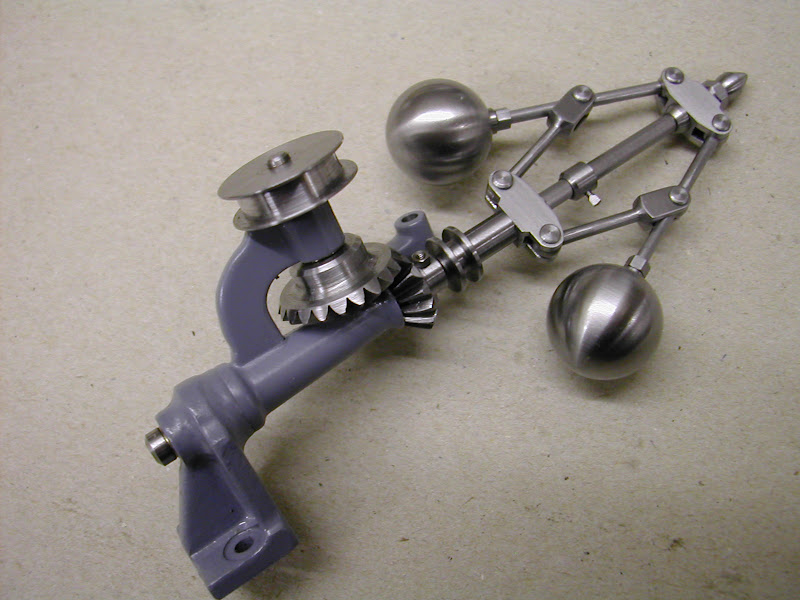

Nothing much to report - it's been a long, not quite but almost, non-workshop day with a visit to the enemy, sorry - mother in law taking precedence but I have made a start on the tooling for making the gear cutters tonight.

Andy, in the New Year you'd be more than welcome to come over and have a 'mardle' (That's Suffolk slang for chat for you non 'Suffolk Boy's') and see whats doing - I'll get the kettle on .

.

Kind Regards - Ramon

It really is very nice of all of you to say such nice things and perhaps a mite rather embarassing particularly as I'm very new on the block round here.

I can only say - I just love making models and have done so for most of my 67 years and do love to share the outcome with anyone that is interested. Model making in various forms and interests throughout those years has always figured high on the priority list despite having a varied career - and one which model making has certainly 'interfered' with at times. I guess it would be fair to say that apart from my long suffering but totally supportive wife Sue it is my overiding passion on a day to day basis.

Before being able to be part of something like this on the ME forum and recently on here it was very much a case of the odd occasion on a 'Bit's and Pieces' night whilst a member of the NDSME and laterly once a year at the Forncett Steam Museum's Model Engineers Day Out. I've always believed, that as a member of any group, you will only get out what you are prepared to put in. Forgive the patently obvious but on here it can be done daily and the contact for all concerned is such an asset to our individual take on the hobby.

I really don't see myself as anything other than someone who enjoy's his modelling and am well aware of it's limitations. When I see the work of others on here and elsewhere I can only marvel at their ingenuity, their dedication to the task and their abilities. It is all relative between each and every one of us but all to a common cause.

Over many years, no doubt like so many of us, I have seen some truly stunning models at exhibitions. I have always tried to allow that to influence my thinking - not always on a try to do likewise and certainly not to try to 'out do' but to just try to do the best I can and improve a little each time. Perfection, like beauty, is definitely in the eye of the beholder. It's how you use it that's down to the individual.

Hope you can see where I'm coming from and that you won't see that as anything other than sincere

Nothing much to report - it's been a long, not quite but almost, non-workshop day with a visit to the enemy, sorry - mother in law taking precedence but I have made a start on the tooling for making the gear cutters tonight.

Andy, in the New Year you'd be more than welcome to come over and have a 'mardle' (That's Suffolk slang for chat for you non 'Suffolk Boy's') and see whats doing - I'll get the kettle on

Kind Regards - Ramon