Yup.  I'm following Kozo's method of drill, bore, ream.

I'm following Kozo's method of drill, bore, ream.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3/4" Pennsy A3

- Thread starter SilverSanJuan

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I've noted that there are no provisions for oiling the journal bearings on the tender trucks in Kozo's design. Do they not need oiling that often? I was considering drilling an oiling hole in the outer face of the journal boxes. I would then fabricate a little hinged cover plate like the prototypes. Is this something that is reasonable to do, or would I be creating more trouble for myself further down the road?

Also, can I use CRS in the construction of the tender truck frames? Or, is brass advised here?

Thanks,

Todd

Also, can I use CRS in the construction of the tender truck frames? Or, is brass advised here?

Thanks,

Todd

- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

The bearings are phosphor bronze, and shouldn't need lubrication. I would use steel vs. brass everywhere I could.

Thanks. I didn't know that about bronze. I was sure it would need some oil.

CRS will make this project a whole lot more affordable. I imagine that I should use the brass and copper on the tender tank for the corrosion resistance.

CRS will make this project a whole lot more affordable. I imagine that I should use the brass and copper on the tender tank for the corrosion resistance.

Well, no pictures... But, I did finish my two spare wheels and the final axle. So, the tender wheels are complete aside from painting and assembling them to the axles.

In the mean time, I'm building the height gauge. Also, need to make the wiggler center finder and angle jigs for the journal boxes. And, I have material to make the frame bending device.

In the mean time, I'm building the height gauge. Also, need to make the wiggler center finder and angle jigs for the journal boxes. And, I have material to make the frame bending device.

Question... what is an acceptable modification to the thread specs that Kozo calls for in the A3? Can I substitute 2-56 and 4-40 for the 1-64 and 3-48 that he calls for in many places?

Tin Falcon

Well-Known Member

- Joined

- Jul 9, 2007

- Messages

- 7,207

- Reaction score

- 787

I would think what he specified would be the best size. but it seems that what was once common is no longer common and odd Gage size hardware is rare these days. Brownells gunsmithing supplies caries some odd sized hardware as well as taps. that being said you can probably go up or down one size and be fine.

Some of the better model supply model engineering supply houses also carry this stuff. also mico fasteners.

Tin

Some of the better model supply model engineering supply houses also carry this stuff. also mico fasteners.

Tin

Question... what is an acceptable modification to the thread specs that Kozo calls for in the A3? Can I substitute 2-56 and 4-40 for the 1-64 and 3-48 that he calls for in many places?

McMaster Carr has them in cap head, flat head, and button head if that would help.

Thanks for the input guys. I'm gonna go ahead and invest in these odd tap sizes. And, Micro-Fasteners does have a full variety of screws available. I hope to have some progress to show in the next week.

- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

Question... what is an acceptable modification to the thread specs that Kozo calls for in the A3? Can I substitute 2-56 and 4-40 for the 1-64 and 3-48 that he calls for in many places?

That's what I would do as long as the tap drill holes are not too large for the part. 4-40 fasteners will be a lot cheaper than 3-48.

Thanks for the input.

OK, just received all materials, screws, and taps for the tender truck frames. Hope to have some progress/pictures to post by the end of the weekend.

The springtime "honey do" list has been keeping me busy. Along with making the height gauge to mark parts. But, that is almost done. I just need to finish the base on it.

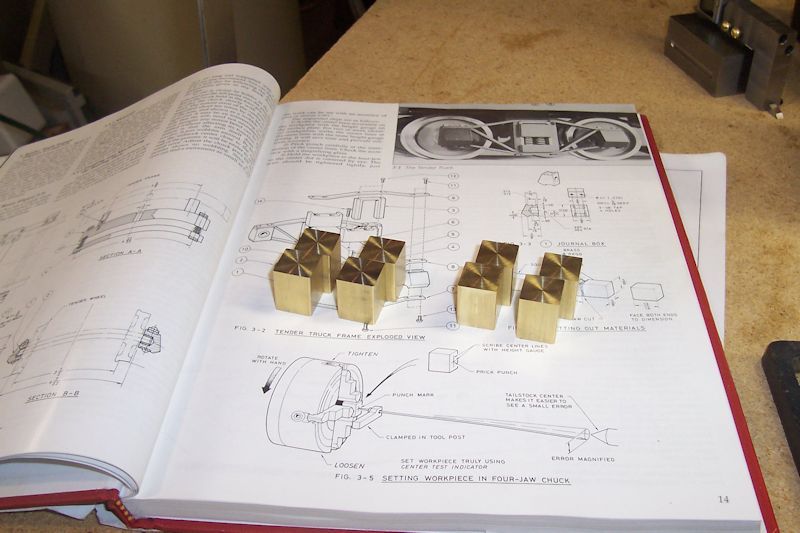

But, just to show something here.... This is all the material for the Archbar truck frames and the tender frame.

Hope to have some actual progress on this later in the week.

Todd

But, just to show something here.... This is all the material for the Archbar truck frames and the tender frame.

Hope to have some actual progress on this later in the week.

Todd

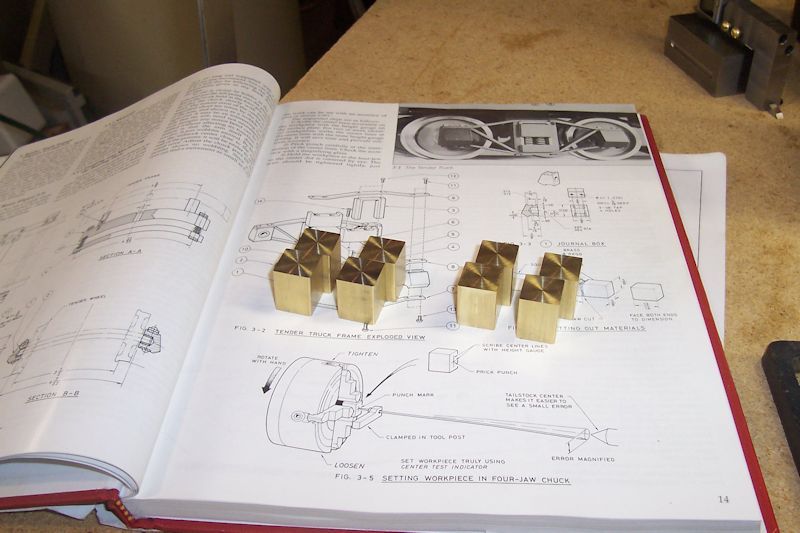

Some minor progress so far this weekend. I cut all the journal boxes from the 5/8" brass stock. Then turned them all to the final height of 13/16". So, now I have eight journal boxes that need to be marked and drilled for the bearings. I also finished my height gauge so that I can mark the centers for the bearings.

Here are the journal boxes:

Here's my height gauge:

Next I need to make the center finder tool. Fun, fun.

Todd

Here are the journal boxes:

Here's my height gauge:

Next I need to make the center finder tool. Fun, fun.

Todd

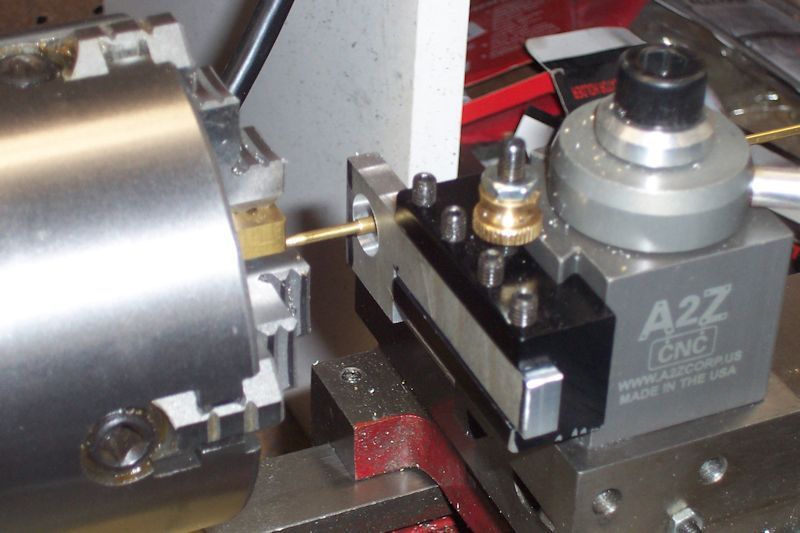

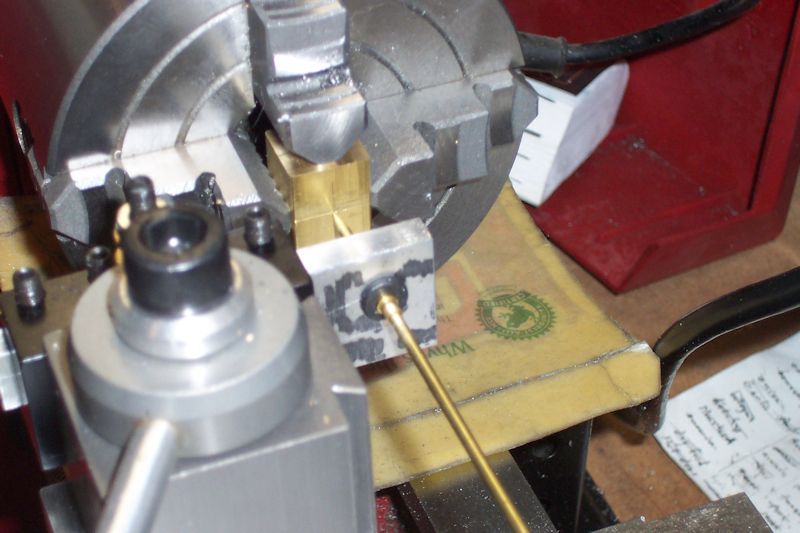

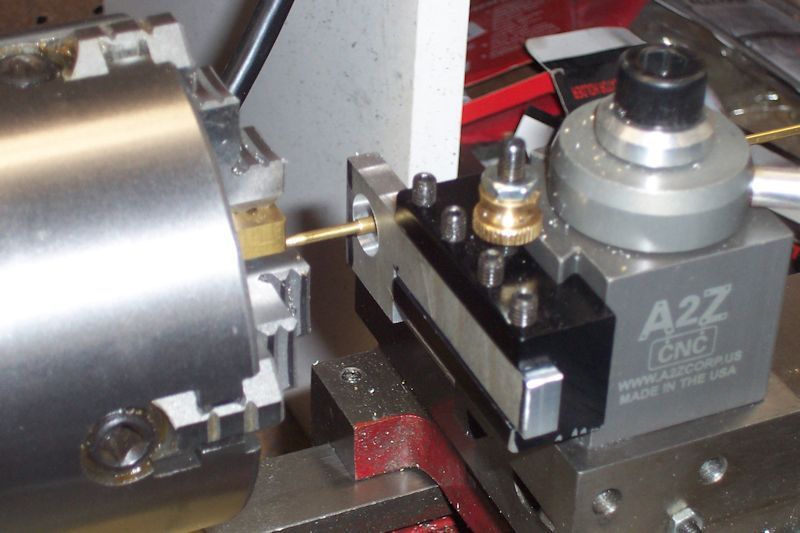

I made my version of Kozo's tool for centering the journal box in the four jaw.

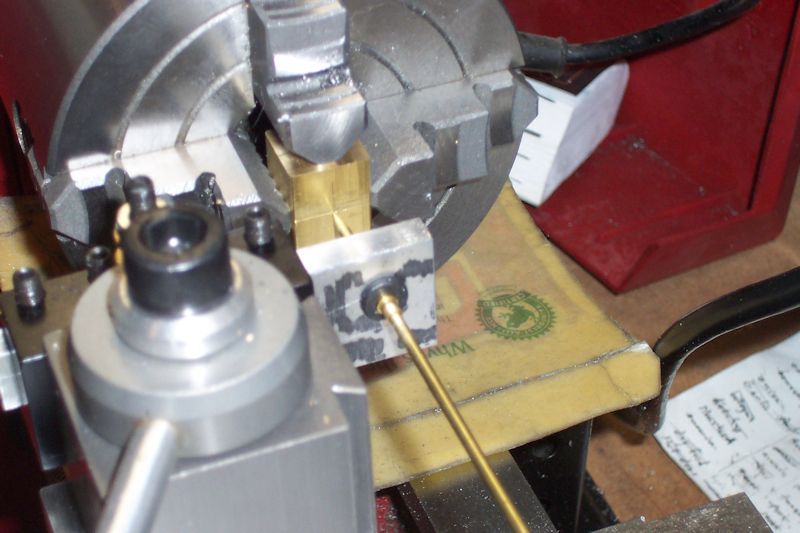

And, from the other end.

The brass wire is supported by a rubber grommet which is fitted into the aluminum holder. Works beautifully. More progress ahead.

Todd

And, from the other end.

The brass wire is supported by a rubber grommet which is fitted into the aluminum holder. Works beautifully. More progress ahead.

Todd

I've got all the journal boxes bored. And, I've started milling the grooves for the arch bar frames. No pictures to show because I'm packing up the shop. We're moving to a nearby town. Moving to a smaller home. but, it has a MUCH bigger basement.  I hope to have the shop back up and running by July. Have to see how things go though. My middle son is graduating from high school and my parents will be in town for that this month. So, shop ops will be on hold till that is all done.

I hope to have the shop back up and running by July. Have to see how things go though. My middle son is graduating from high school and my parents will be in town for that this month. So, shop ops will be on hold till that is all done.

But, having a bigger shop area is gonna be soooo much better.

Todd

But, having a bigger shop area is gonna be soooo much better.

Todd

- Joined

- May 14, 2011

- Messages

- 683

- Reaction score

- 185

Good luck Todd .I am building this same engine ,If you have any questions feel free to ask . Dale

Thanks Dale.  How far along are you on your project?

How far along are you on your project?

Todd

Todd

WooHoo! Finished setting up the shop.  Took a lot longer than anticipated. But, what doesn't, right?

Took a lot longer than anticipated. But, what doesn't, right?

Finished with the grooves on the journal boxes. And, made the drilling jig for drilling the 32 holes. I'll get some pictures of the new shop and progress posted soon.

Todd

Finished with the grooves on the journal boxes. And, made the drilling jig for drilling the 32 holes. I'll get some pictures of the new shop and progress posted soon.

Todd

Similar threads

- Replies

- 25

- Views

- 3K