Xlmyford

Well-Known Member

- Joined

- Mar 8, 2009

- Messages

- 97

- Reaction score

- 4

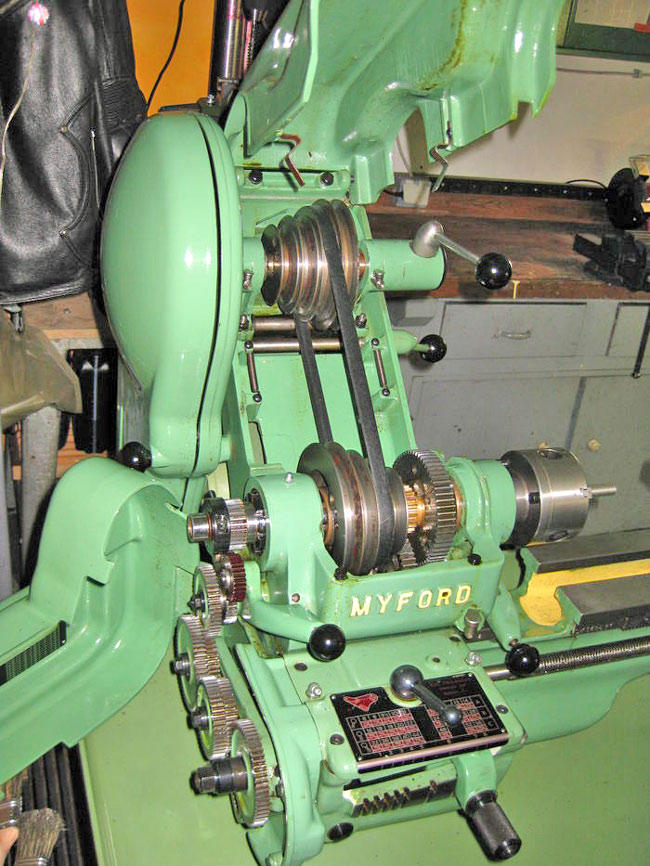

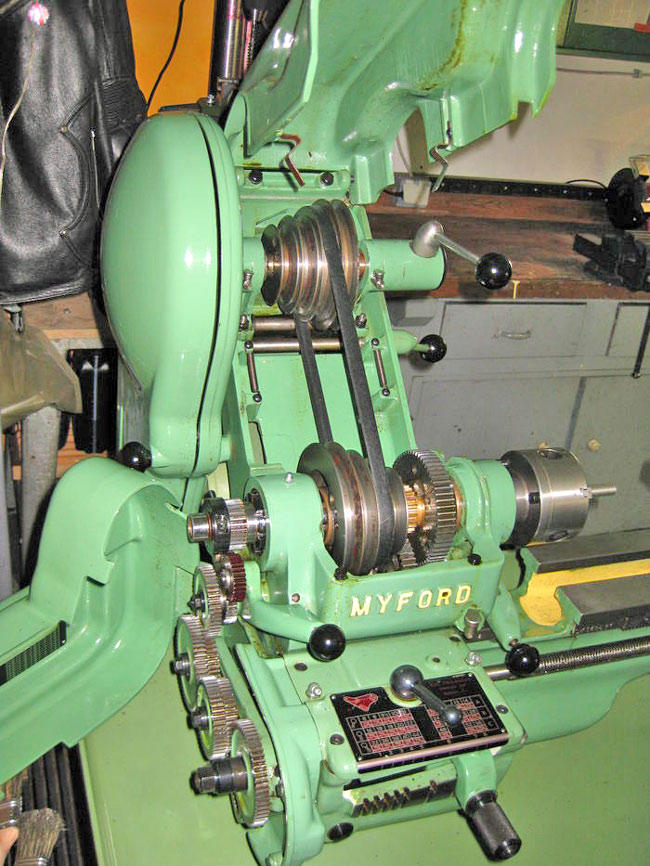

Mine is a Myford Super 7,made in 1973.

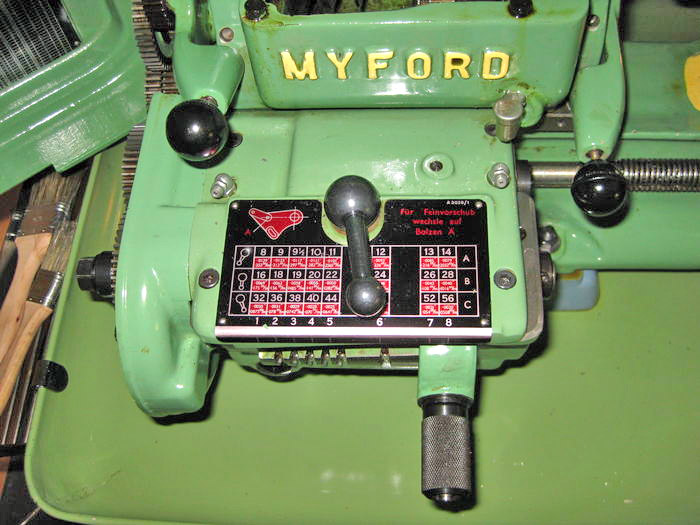

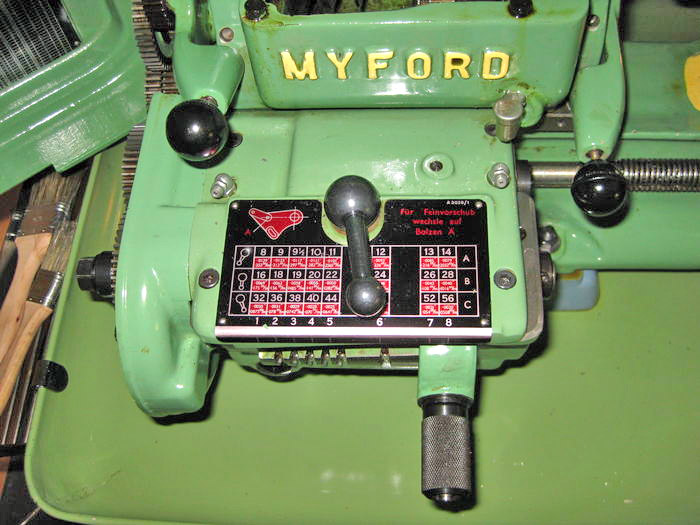

It came with a Norton gearbox.

I bought this British beauty in 2009.

Over the last two years I did some modifications to it,making it even more handy

than it has been anyway.

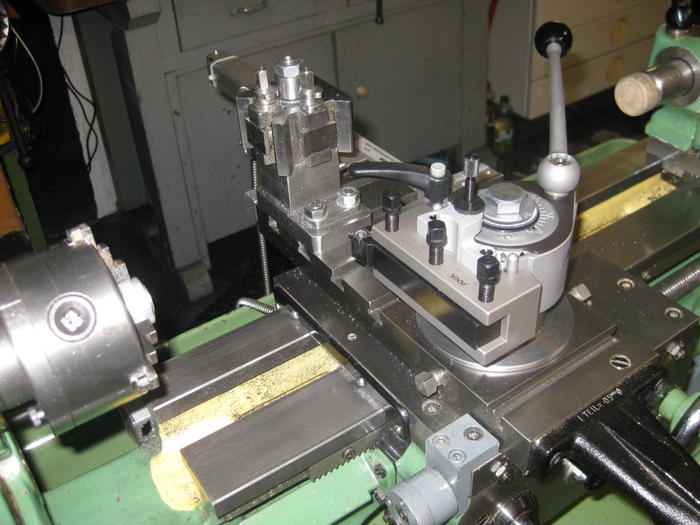

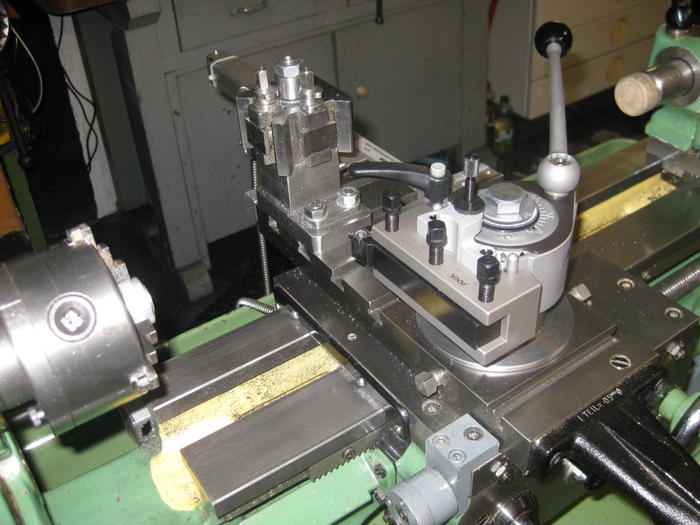

Axa QCTP and a rear toolpost:

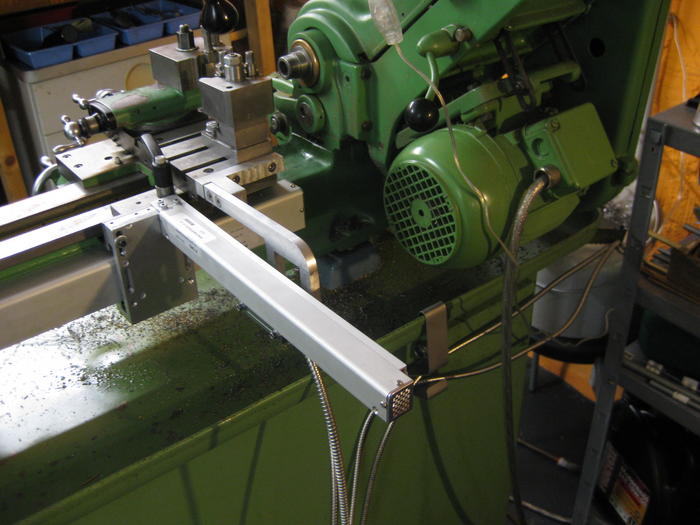

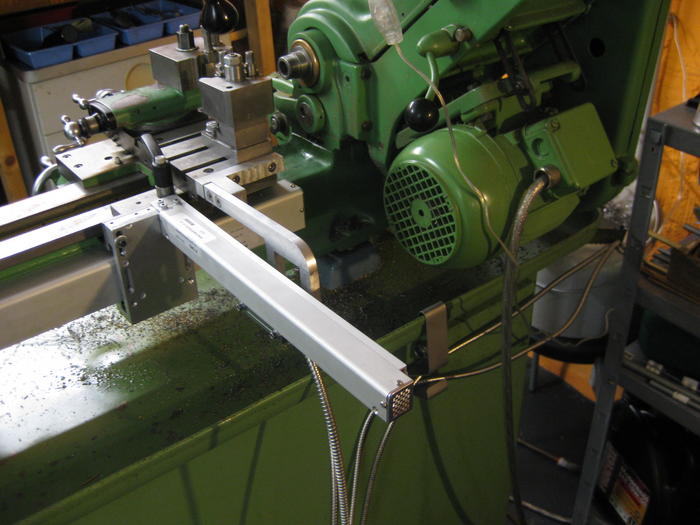

SINO DRO:

I really love that lathe and it´s so sad that the Myford Company is now history.

Cheers,Ralph

It came with a Norton gearbox.

I bought this British beauty in 2009.

Over the last two years I did some modifications to it,making it even more handy

than it has been anyway.

Axa QCTP and a rear toolpost:

SINO DRO:

I really love that lathe and it´s so sad that the Myford Company is now history.

Cheers,Ralph